Cassegrain metamaterial antenna

A technology of metamaterials and antennas, applied in the field of communication, can solve the problems of difficult processing and high cost of Cassegrain antennas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

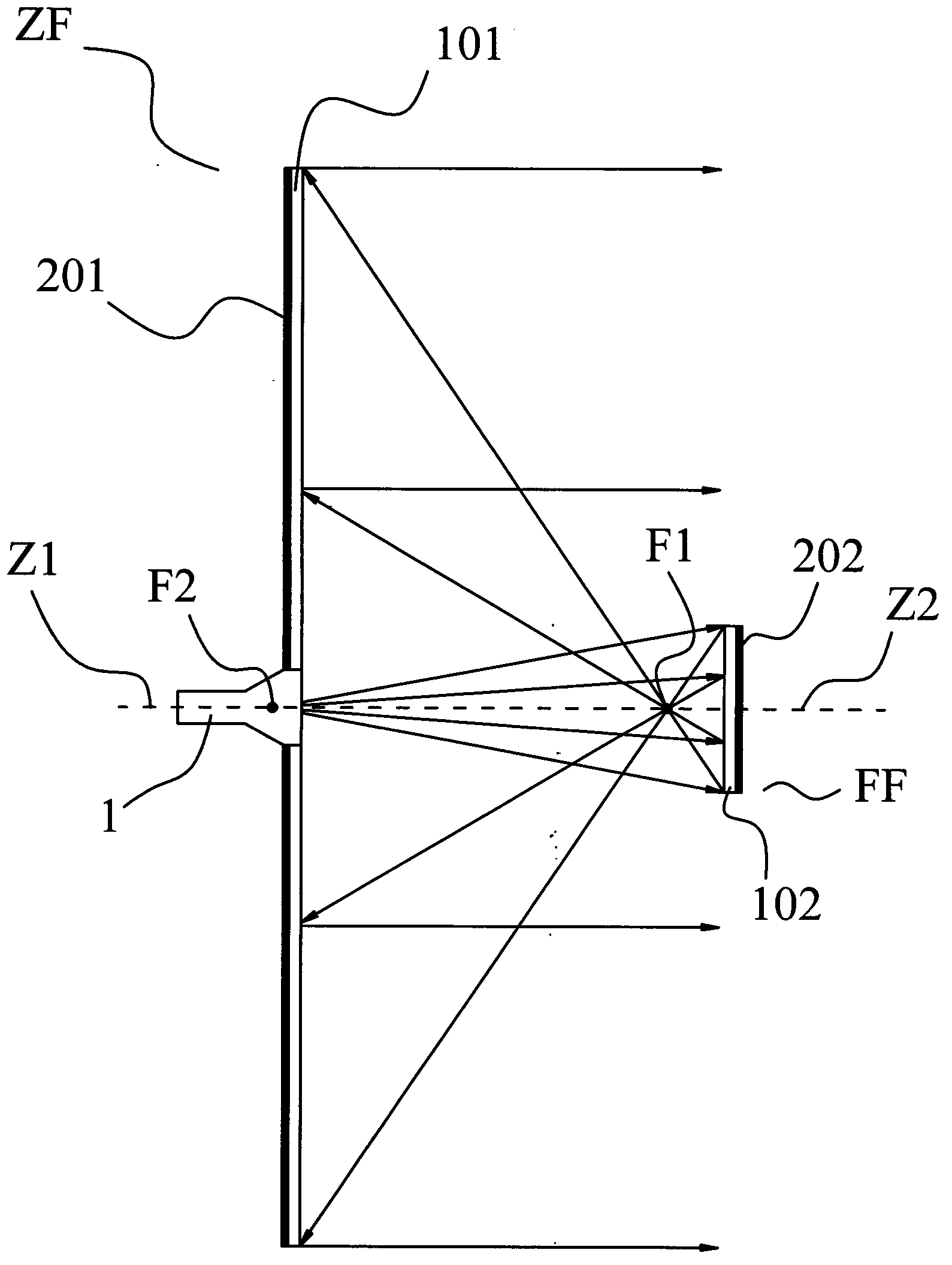

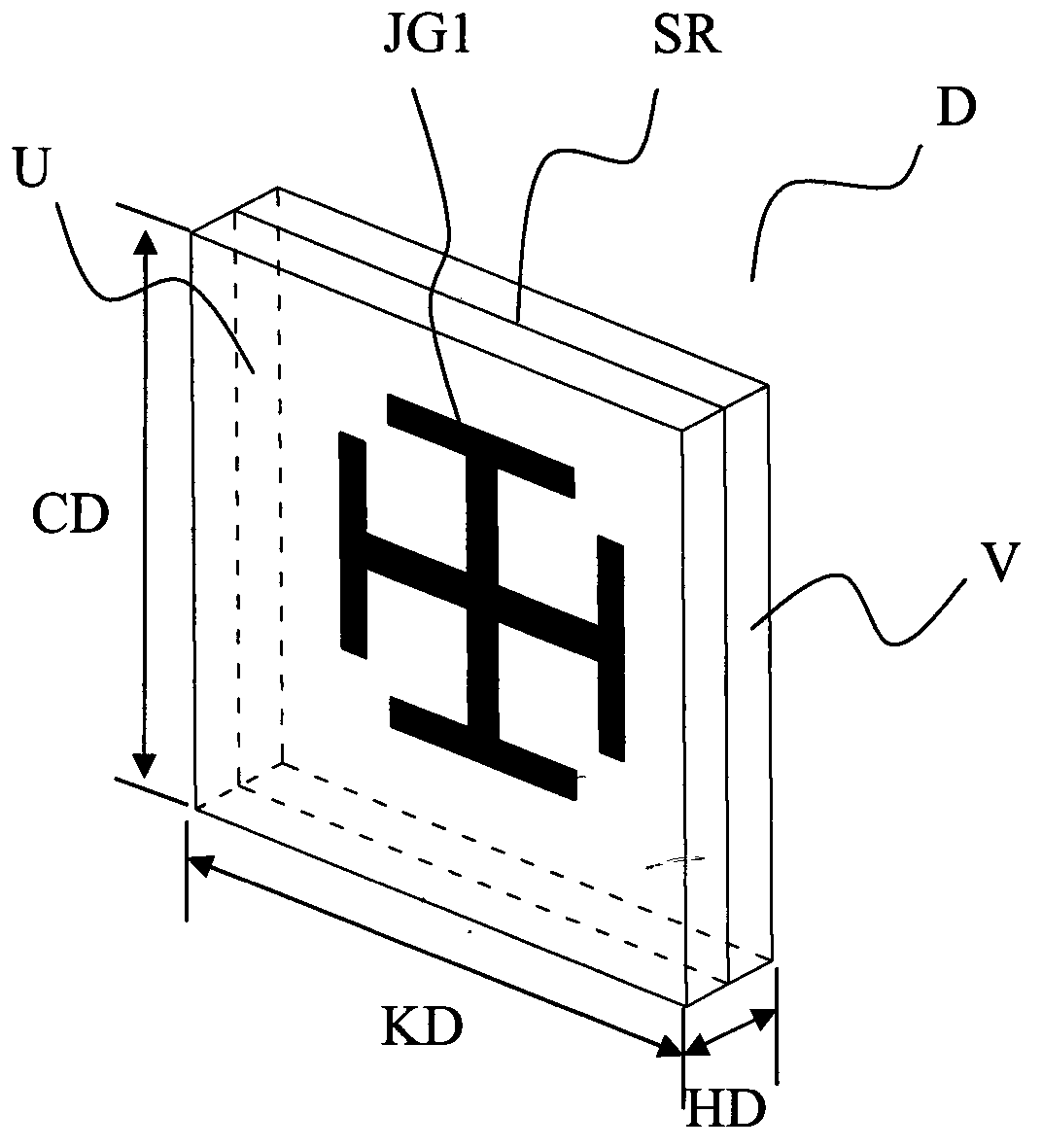

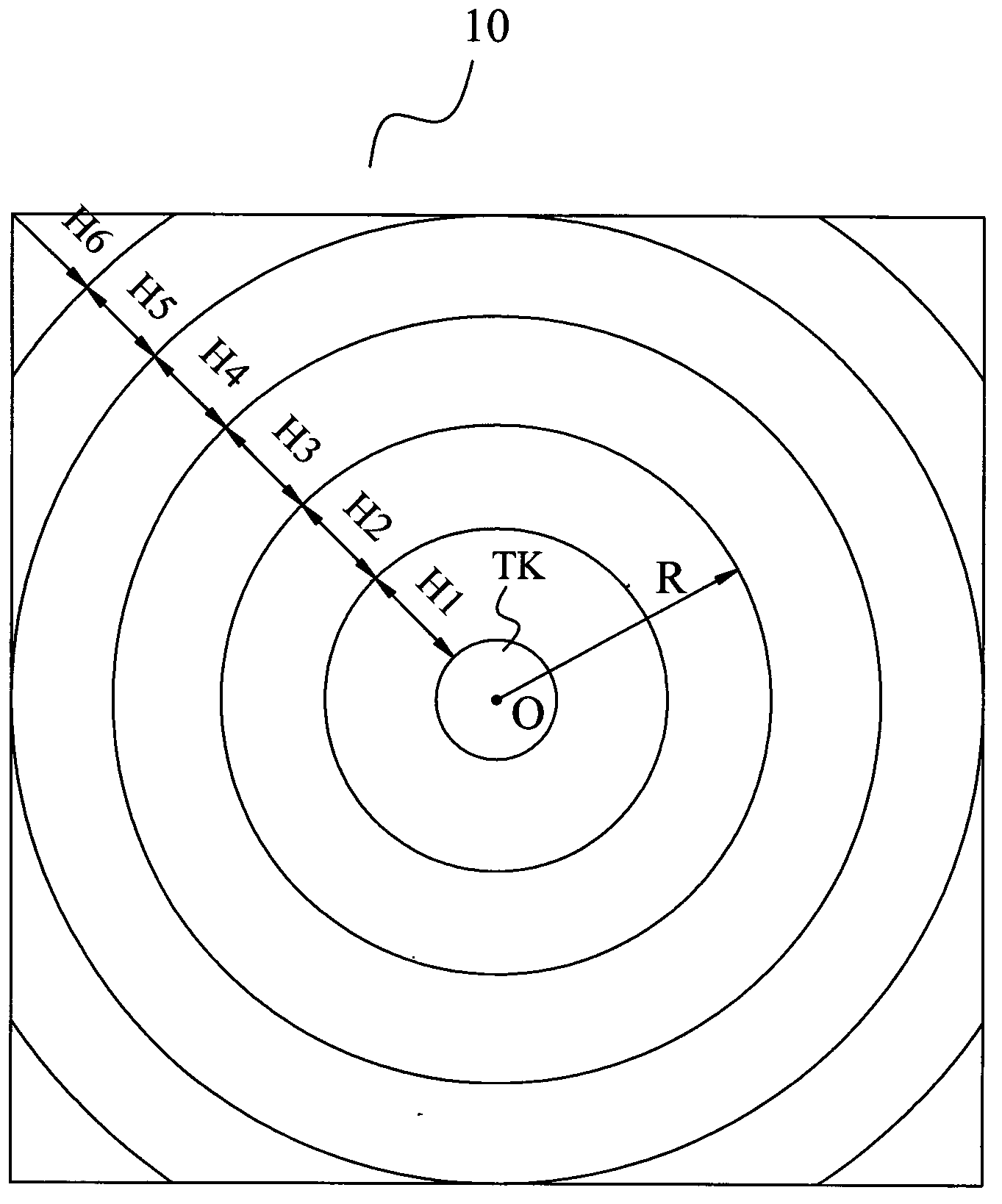

[0048] Such as Figures 1 to 4As shown, the Cassegrain type metamaterial antenna according to the present invention includes a metamaterial main reflector ZF with a central through hole TK, a feed source 1 arranged in the central through hole TK and a metamaterial secondary reflector arranged in front of the feed source 1 The electromagnetic waves radiated by the reflector FF and the feed source 1 are emitted in the form of plane waves after being reflected by the metamaterial sub-reflector FF and the metamaterial main reflector ZF in turn. The metamaterial main reflector ZF includes a first core layer 101 and a set The first reflective layer 201 on the rear surface of the first core layer 101, the first core layer 101 includes at least one first core layer sheet 10, and the first core layer sheet 10 includes a first base material JC1 and a set A plurality of first artificial microstructures JG1 on the first substrate JC1, the metamaterial sub-reflector FF includes a second co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com