Method for producing a plastic article and blow molding tool

A technology of blow molding molds and plastic products, which can be applied to household appliances, other household appliances, applications, etc., and can solve problems such as high equipment costs and non-diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

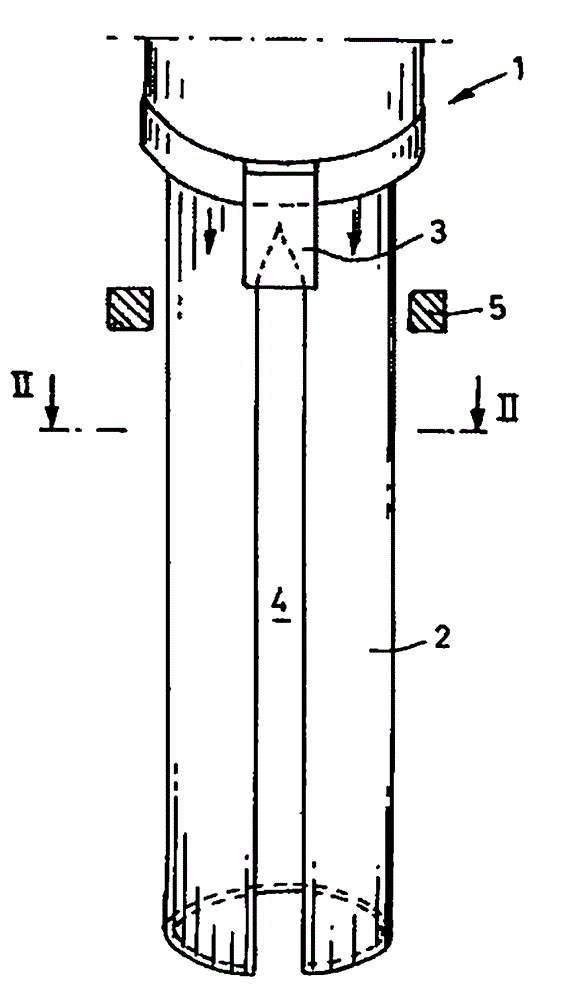

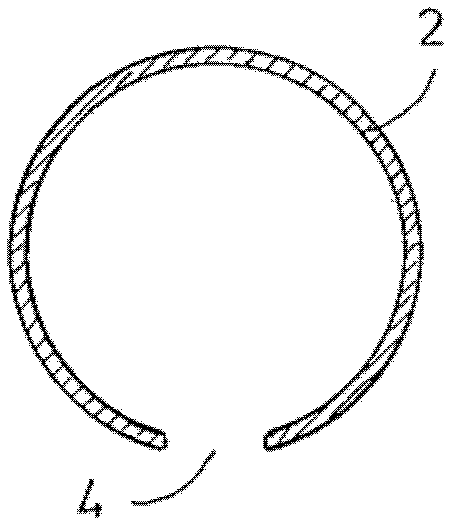

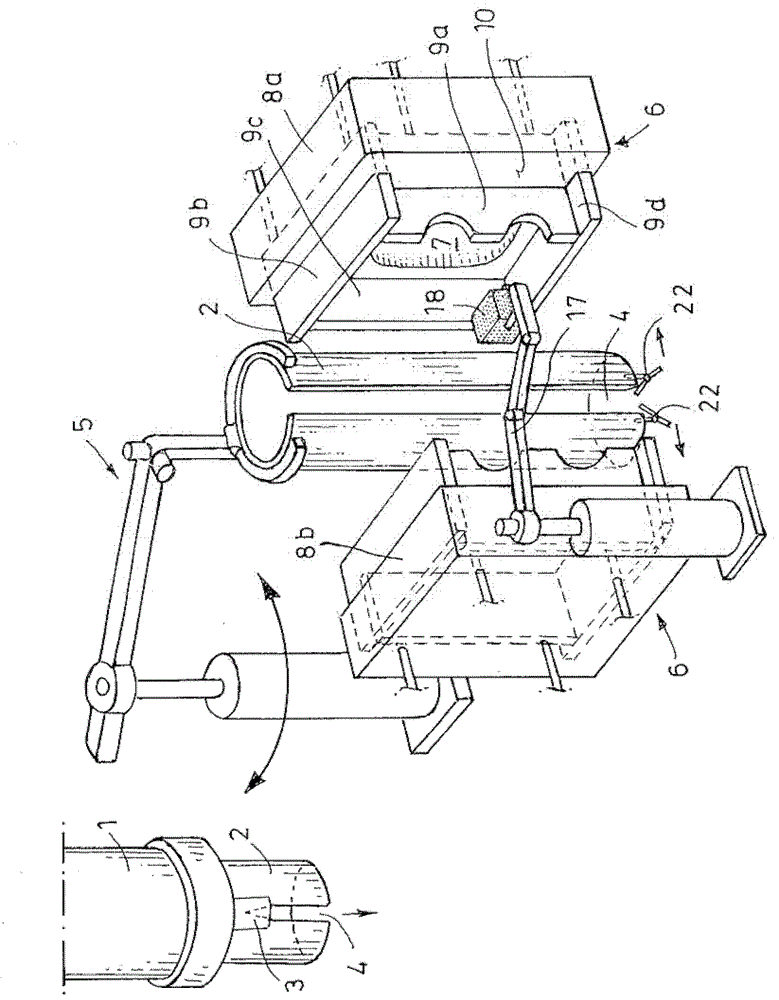

[0053] exist figure 1 The steps of extruding a substantially tubular preform according to the invention are first shown in . Firstly, a tubular preform made of thermoplastic material emerges from the extrusion head denoted by the reference numeral 1 in a molten state, passing through an annular gap of the extrusion head 1 in a known manner. Nozzle discharge. The extrusion can be carried out continuously or discontinuously. In the illustrated embodiment, the preformed tube (Vorformlingschlauch) 2 is separated on one side according to the length by means of the separating device 3, so that the preformed tube has figure 2 The cross-sectional shape shown in , ie provided with longitudinal slits 4 . For example heat-sealing knives, movable blades, lasers or the like are considered as the separating means.

[0054] The separation of the preformed tube 2 can, as in the illustrated embodiment, be performed outside the extrusion head after or during the exit of the preformed tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com