Methods for attaching thermoplastic profile to roofing membrane and dual welding device

A thermoplastic film and thermoplastic technology, applied in the direction of roofing, roofing, and roof coverings using flexible materials, can solve the problems of cost reduction advantages, disadvantages, and increased roofing costs, and achieve novel cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

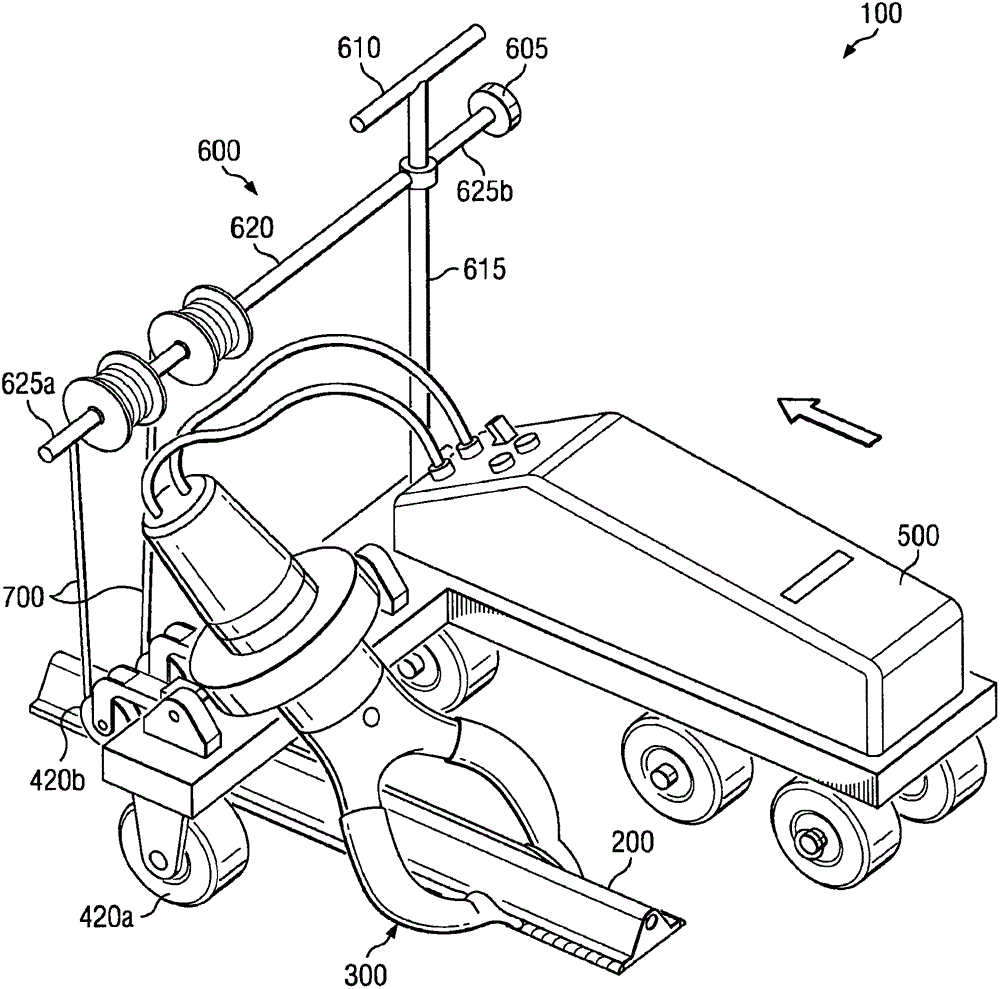

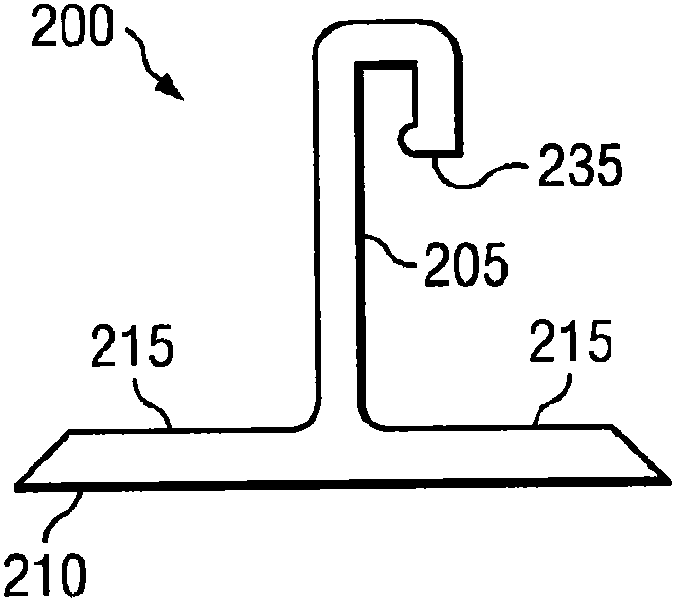

[0028] figure 1 A first exemplary embodiment of a dual welding machine 100 for welding thermoplastic profile strips 200 to thermoplastic roofing membranes is shown. The dual splicer 100 includes a split nozzle 300 , a splicer platform 400 , a splicer drive unit 500 , and a splicer supply device 600 . Throughout the drawings, the same reference numerals are used to describe similar components of the dual fusion splicer 100 .

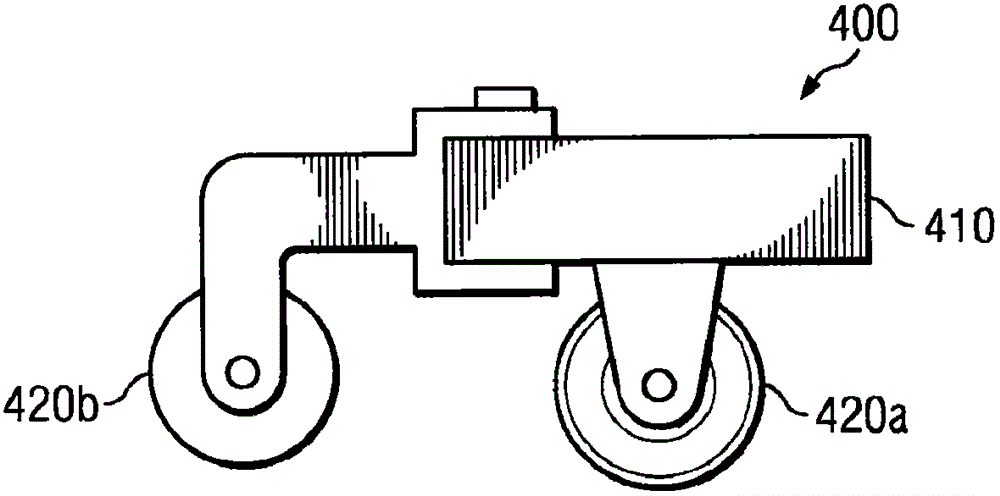

[0029] Figure 1Ais a side view of the fusion splicer platform 400 . In one embodiment, the splicer platform 400 includes a platform 410 and one or more wheels 420 . In some embodiments, there is a first wheel 420a and a second wheel 420b. In some embodiments, there is a pair of first wheels 420a and a pair of second wheels 420b. In some embodiments, the pair of wheels 420a straddles the strip of thermoplastic profile 200 , while in other embodiments, the pair of wheels 420a does not straddle the strip of thermoplastic profile 200 . In some embodim...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap