Anti-overflow moisture-preserving electric cooker and cooking control method thereof

A control method and technology of an electric rice cooker, applied in the direction of preventing overflow, steam cooking utensils, cooking utensils, etc., can solve the problems of energy waste, unfavorable cooking food, etc., and achieve the effect of reliable anti-overflow function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

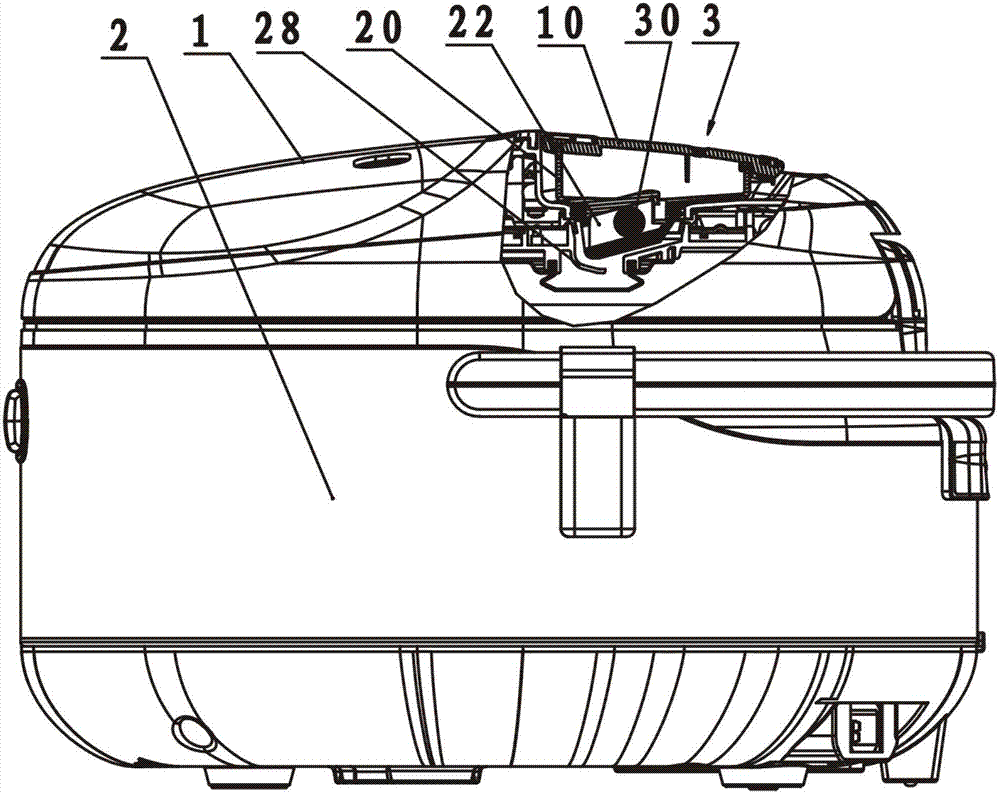

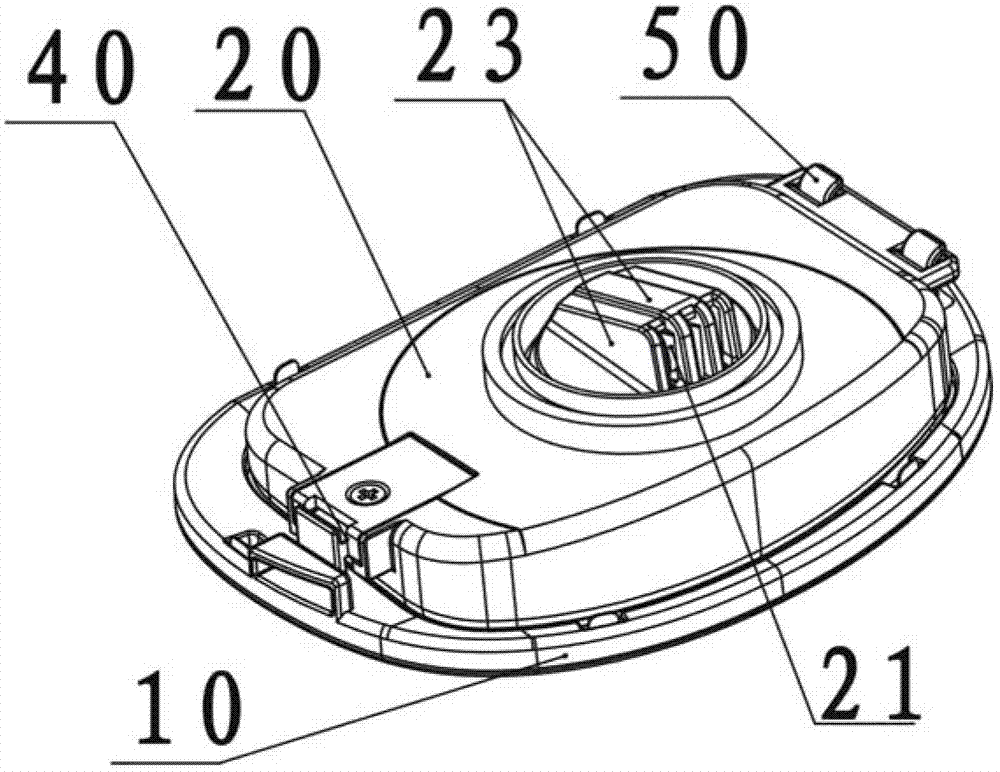

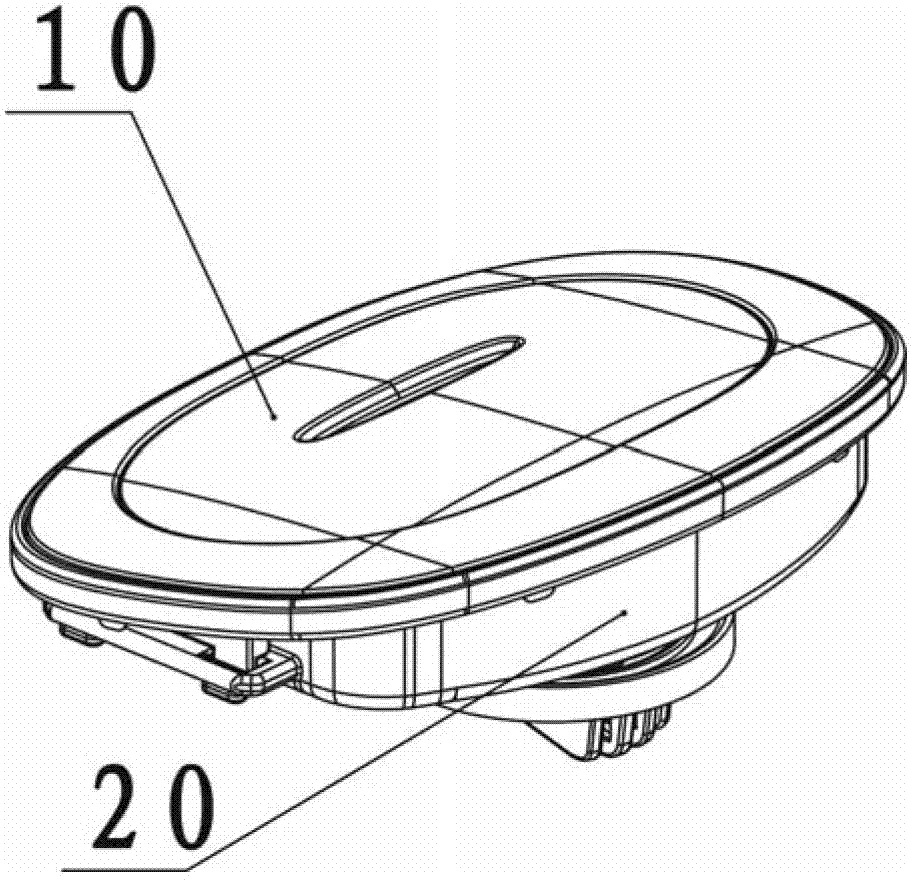

[0062] The embodiment of the present invention provides an electric rice cooker, which includes a pot cover 1 and a pot body 2, and the pot cover 1 is provided with a steam valve 3, so that a certain humidity can be maintained in the electric rice cooker, such as figure 2 and image 3 As shown, the steam valve 3 provided by the embodiment of the present invention includes an upper valve cover 10 and a lower valve cover 20 fitted together, and an exhaust hole 21 is provided on the lower valve cover 20; in order to maintain a certain humidity in the pot, Such as figure 2 As shown, the exhaust valve of the embodiment of the present invention is provided with an accommodating space ( figure 2 not shown in), the accommodating space in the figure 2 The center is surrounded by the plate 23 in the figure, and a valve body 30 that blocks a part of the exhaust hole 21 is placed in the accommodating space (see figure 1 As shown), after part of the exhaust hole 21 is blocked, the s...

Embodiment 2

[0083] The embodiment of the present invention provides a cooking control method for an electric rice cooker. The electric rice cooker adopts the structure provided in Embodiment 1, which can refer to the description in Embodiment 1, and will not be repeated here. The cooking control method for an electric rice cooker includes Detection step A: within the first predetermined time after starting the cooking function of the electric rice cooker, if the sensor detects that the valve body is far away from the exhaust hole, stop heating; It will not stay away from the exhaust hole due to the push of water vapor, so it can be determined that the steam valve is missing or the lid is not closed in place, so the heating needs to be stopped; of course, the user can also be prompted in other ways at this time, such as alarm prompts or Indicates the status of heating stop, etc.

[0084] Of course, in order to prevent overflowing during the cooking process, the cooking process of the rice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com