Tool for loading protective sleeve to automobile drag cable and loading method thereof

A tooling and sheathing technology, which is applied in the field of automobile cables, can solve the problems of unreliable fixing of protective tubes and sheaths, low production efficiency, and high production costs, and achieve the effects of convenient sheathing, high production efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

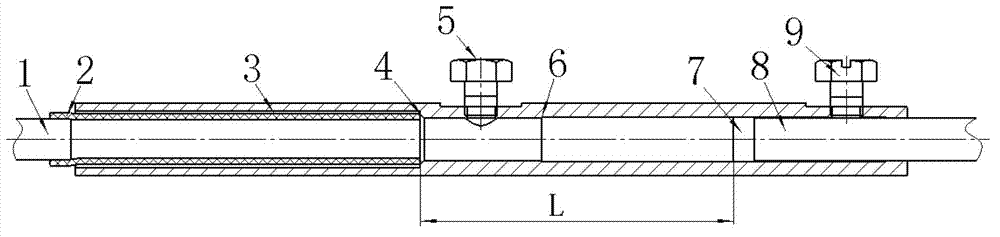

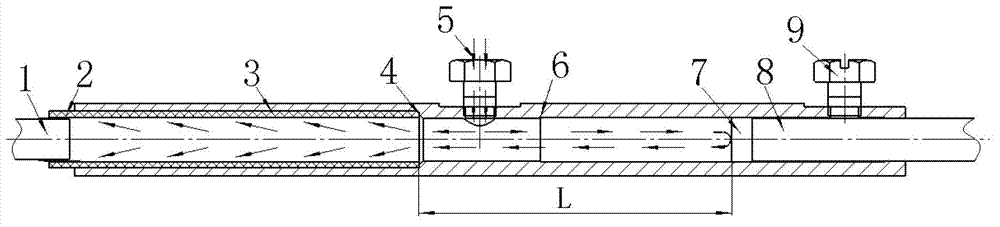

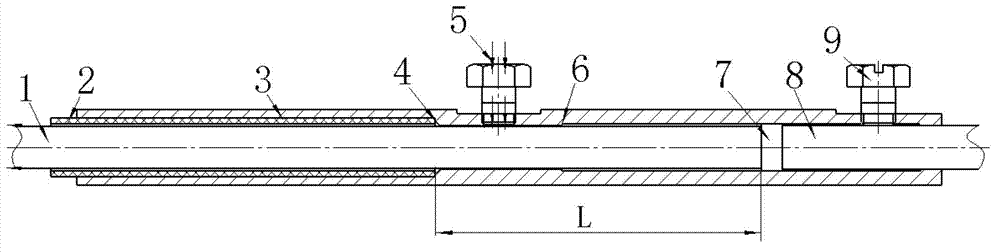

[0019] Such as figure 1 As shown, a kind of automobile cable protection tube wearing tooling, including a tubular tooling body, the inner diameter of a section of the end of the tooling body is greater than the outer diameter of the protective tube 2 in the natural state, and the protective tube 2 is placed in the tooling body, leaving a gap between Expansion gap 3. The other end of the tooling body is a sealed end, and an air inlet 5 is arranged on the tooling body.

[0020] Preferably, the sealing end is sealed by an airtight piston 7 arranged in the tooling body, and the airtight piston 7 is arranged at the end of the adjusting rod 8, and the adjusting rod 8 is fixed by a locking bolt 9 on the tooling body. By adjusting the position of the adjusting rod 8 , the length L of the sheath 1 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com