Bending device for plastic pipeline and using method

A technology of bending device and plastic pipe, which is applied in the field of pipe processing, can solve problems such as difficult to control the bending angle, troublesome disassembly, uncontrollable bending point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

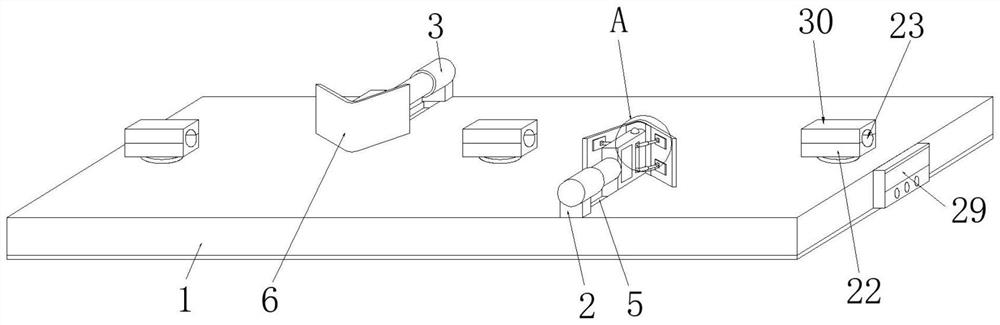

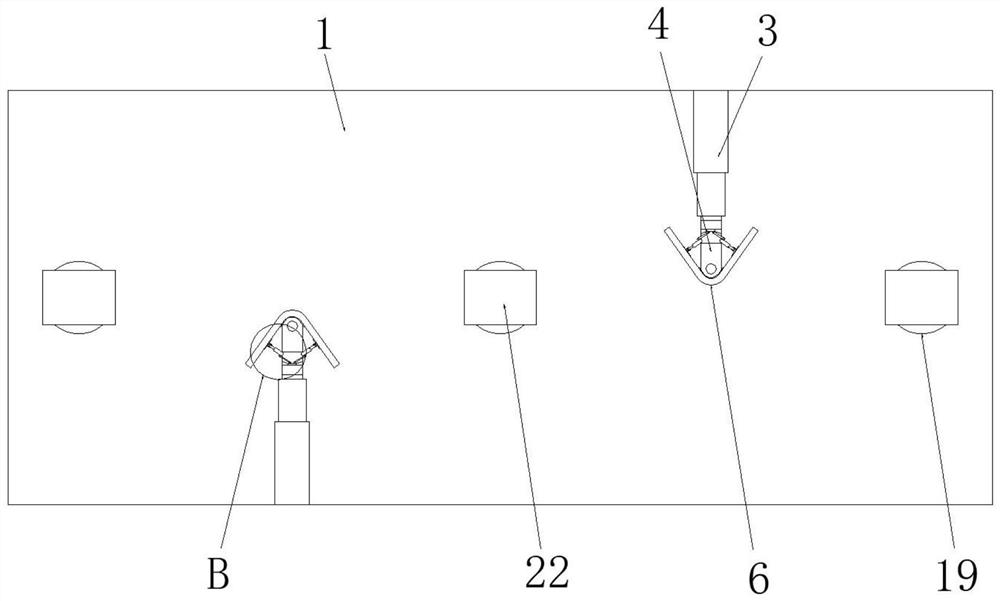

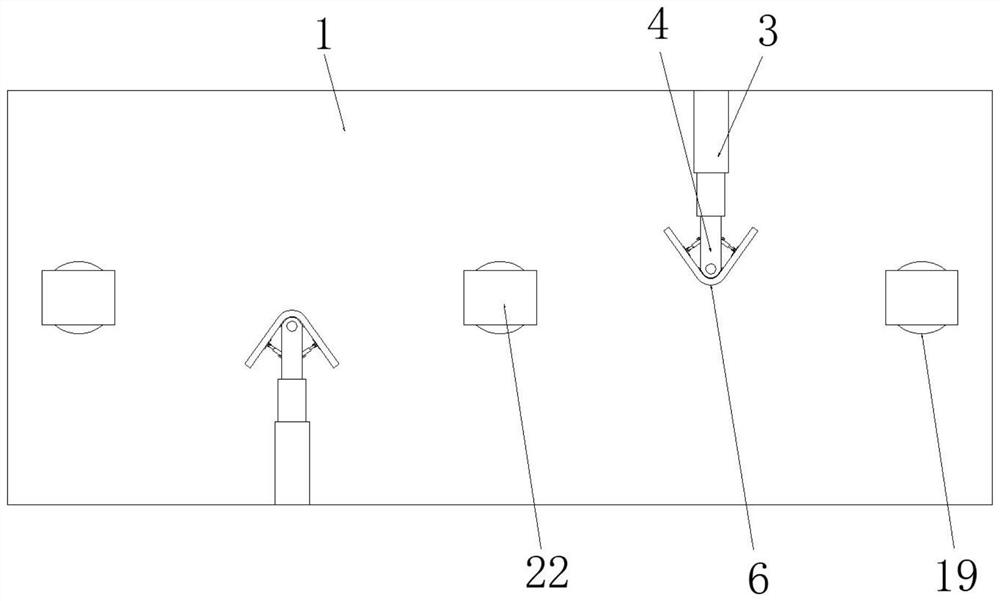

[0037] see Figure 1-8 , the present invention provides a technical solution: a bending device for plastic pipes, including a fixed bottom plate 1, both sides above the fixed bottom plate 1 are fixedly connected with support rods 2, and above the support rod 2 is fixedly connected with a first Electric push rod 3, the other end of the first electric push rod 3 is fixedly connected with a corner plate pushing block 4, the bottom of the first electric push rod 3 is provided with a pushing block chute 5, and the corner plate pushing block 4 is located in the pushing block chute 5 The other end of the angle plate pushing block 4 is fixedly connected with the adjustable pipe angle plate 6, and the first electric push rod 3 is started to extend the adjustable pipe angle plate 6, which can realize the alignment of the straight pipe between the two support rods. A section between 2 is bent, and the adjustable pipe angle plate 6 is composed of the bending end in the middle and the angl...

Embodiment 2

[0040] see Figure 1-8 , the present invention provides a technical solution: a bending device for plastic pipes, including a fixed bottom plate 1, both sides above the fixed bottom plate 1 are fixedly connected with support rods 2, and above the support rod 2 is fixedly connected with a first Electric push rod 3, the other end of the first electric push rod 3 is fixedly connected with a corner plate pushing block 4, the bottom of the first electric push rod 3 is provided with a pushing block chute 5, and the corner plate pushing block 4 is located in the pushing block chute 5 The other end of the angle plate pushing block 4 is fixedly connected with the adjustable pipe angle plate 6, and the first electric push rod 3 is started to extend the adjustable pipe angle plate 6, which can realize the alignment of the straight pipe between the two support rods. A section between 2 is bent, and the adjustable pipe angle plate 6 is composed of the bending end in the middle and the angl...

Embodiment 3

[0046] see Figure 1-8 , the present invention provides a technical solution: a bending device for plastic pipes, including a fixed bottom plate 1, both sides above the fixed bottom plate 1 are fixedly connected with support rods 2, and above the support rod 2 is fixedly connected with a first Electric push rod 3, the other end of the first electric push rod 3 is fixedly connected with a corner plate pushing block 4, the bottom of the first electric push rod 3 is provided with a pushing block chute 5, and the corner plate pushing block 4 is located in the pushing block chute 5 The other end of the angle plate pushing block 4 is fixedly connected with the adjustable pipe angle plate 6, and the first electric push rod 3 is started to extend the adjustable pipe angle plate 6, which can realize the alignment of the straight pipe between the two support rods. A section between 2 is bent, and the adjustable pipe angle plate 6 is composed of the bending end in the middle and the angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com