Y-shaft protective cover for floor-type boring-milling machine

A technology of protective cover, boring and milling machine, applied in maintenance and safety accessories, metal processing mechanical parts, metal processing equipment and other directions, can solve the problems of increased Y-axis lifting power, high production cost, short service life, etc., and achieve increased self-weight The effect of small amplitude, low production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

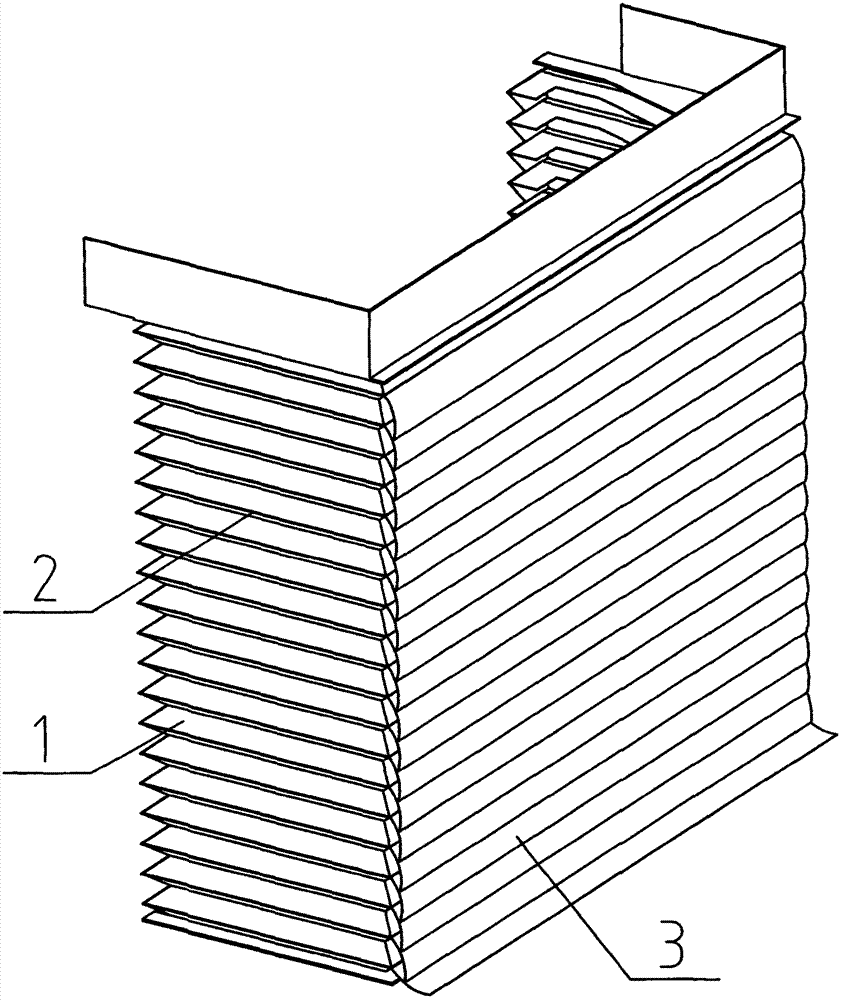

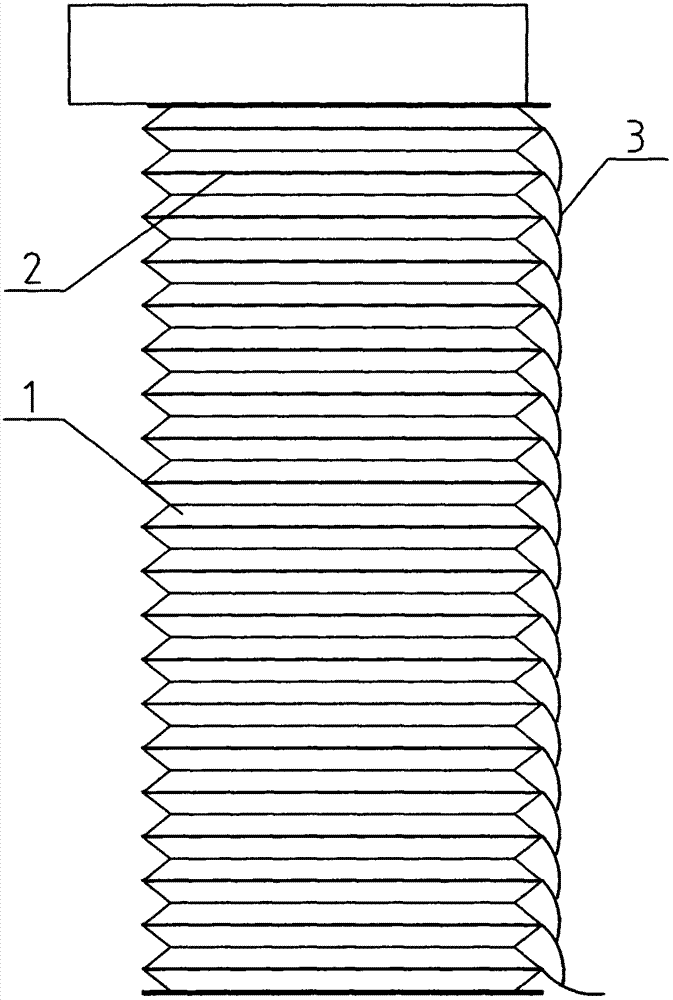

[0012] Embodiment 1: A Y-axis protective cover for a floor type boring and milling machine, the protective cover includes a retractable protective cover body 1, the front end of the protective cover body 1 is provided with 20 folded bones 2, and each folded bone 2 is installed Has metal armor3. The metal protective armor 3 is arranged in an arc-shaped structure, one side of which is fixed on the folding bone 2, and the other sides are freely suspended, and can be stretched or stacked along with the expansion and contraction of the protective cover body 1.

specific Embodiment approach 2

[0013] Embodiment 2: The difference from Embodiment 1 is that in Embodiment 2, there are 10 folded bones 2 .

specific Embodiment approach 3

[0014] Embodiment 3: The difference from Embodiment 1 is that in Embodiment 3, there are 30 folded bones 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com