Unit module mechanism of modular reconfigurable robot

A technology for reconstructing robots and unit modules, applied in the field of robots, can solve the problems of inaccurate adjustment of rotation angle, insufficient movement ability, and low movement efficiency, and achieves the effect of simple structure, convenient reconstruction and combination, and ensuring flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

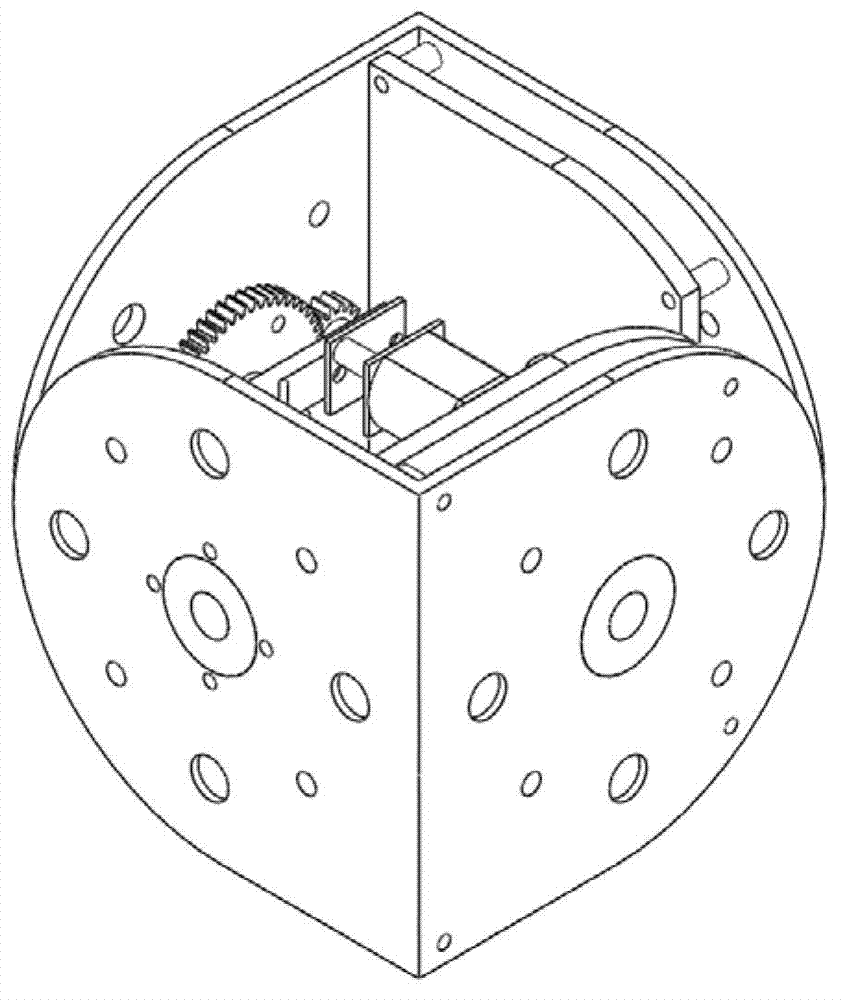

[0024] Such as figure 1 As shown, the unit module mechanism of the present invention consists of two L-shaped front and rear arms with identical structures, and a link device.

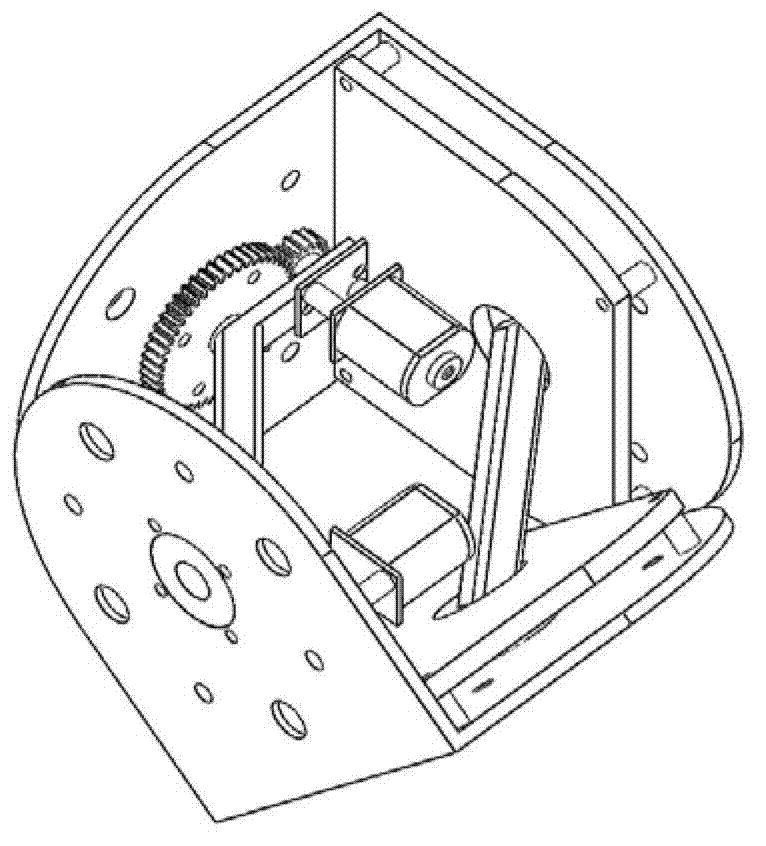

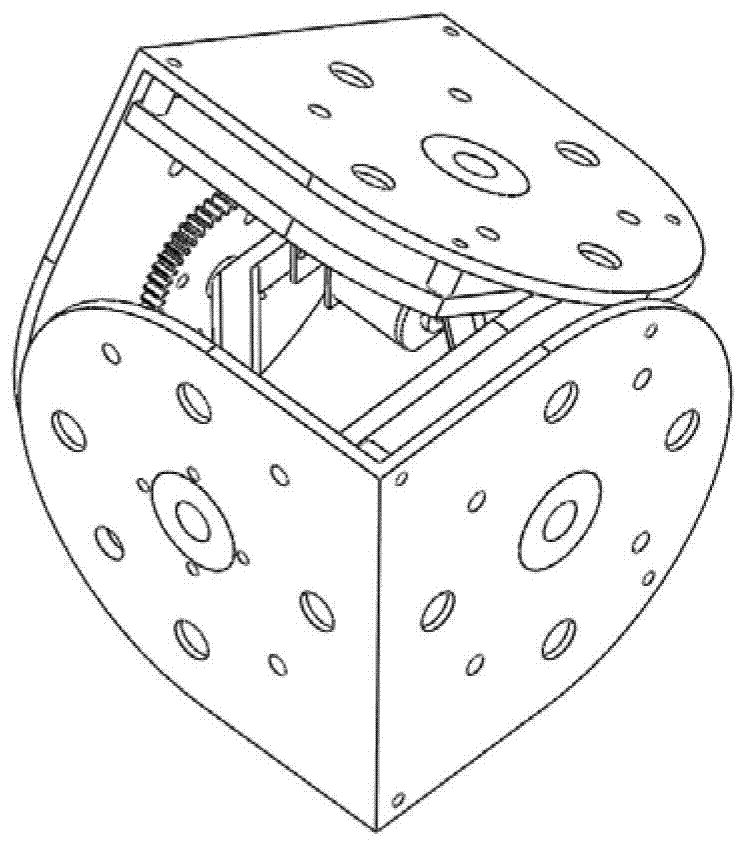

[0025] Such as figure 2 and image 3 As shown, the forearm and the rear arm of the unit module mechanism can be rotated up and down along their respective semicircular arc edges under the drive of the link device, so as to realize the precise adjustment of the interface angle of the forearm or the rear arm.

[0026] Such as Figure 4 and Figure 5 Shown is the overall rotation view and top view of the unit module mechanism. L-shaped forearm comprises forearm L-shaped semicircle outer plate 116, forearm circuit board 112, forearm copper pillar 111,115, forearm bearing 113,117 and forearm rotating gear 119; L-shaped rear arm comprises rear arm L-shaped semicircle outer plate 105 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com