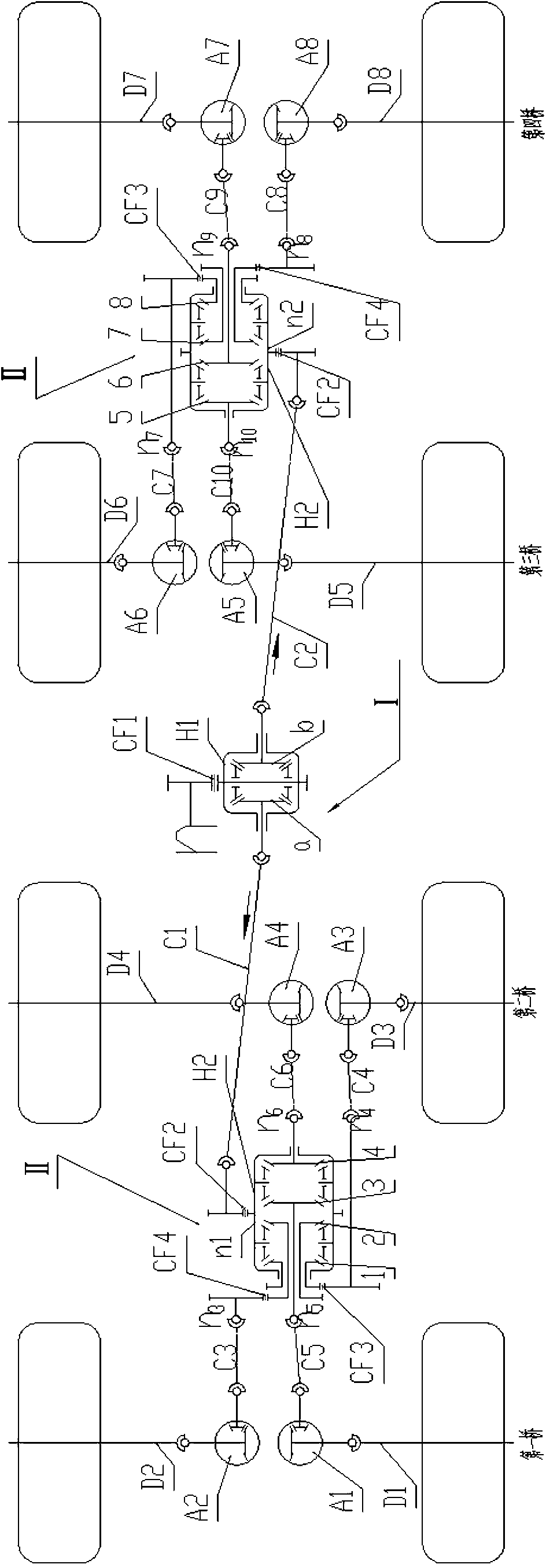

Differential transmission system of full-time eight-wheel drive vehicle

A differential transmission and wheel drive technology, applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problems of low speed, low passing capacity and difficult operation of all-wheel drive, so as to avoid personal safety problems and reduce fuel consumption , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

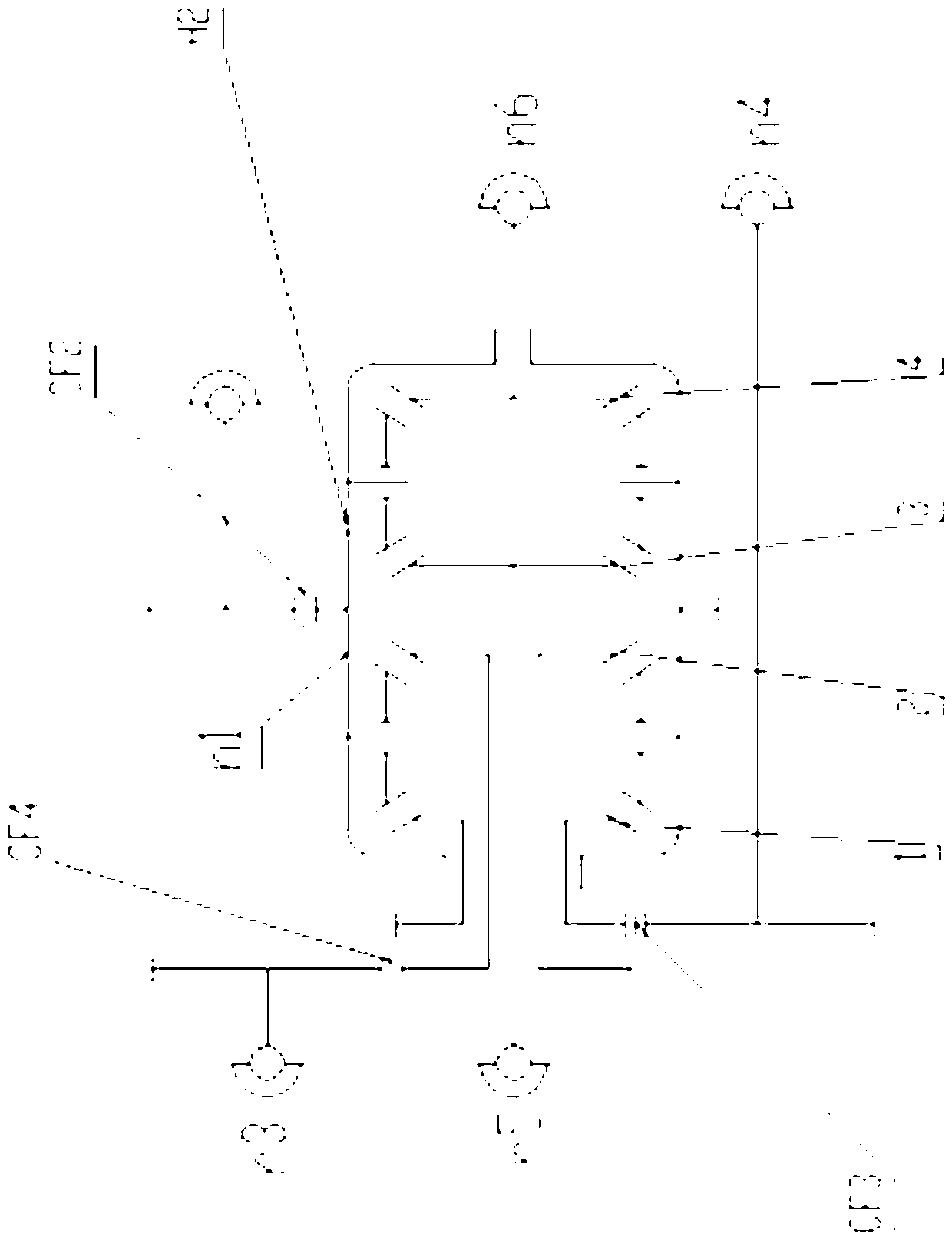

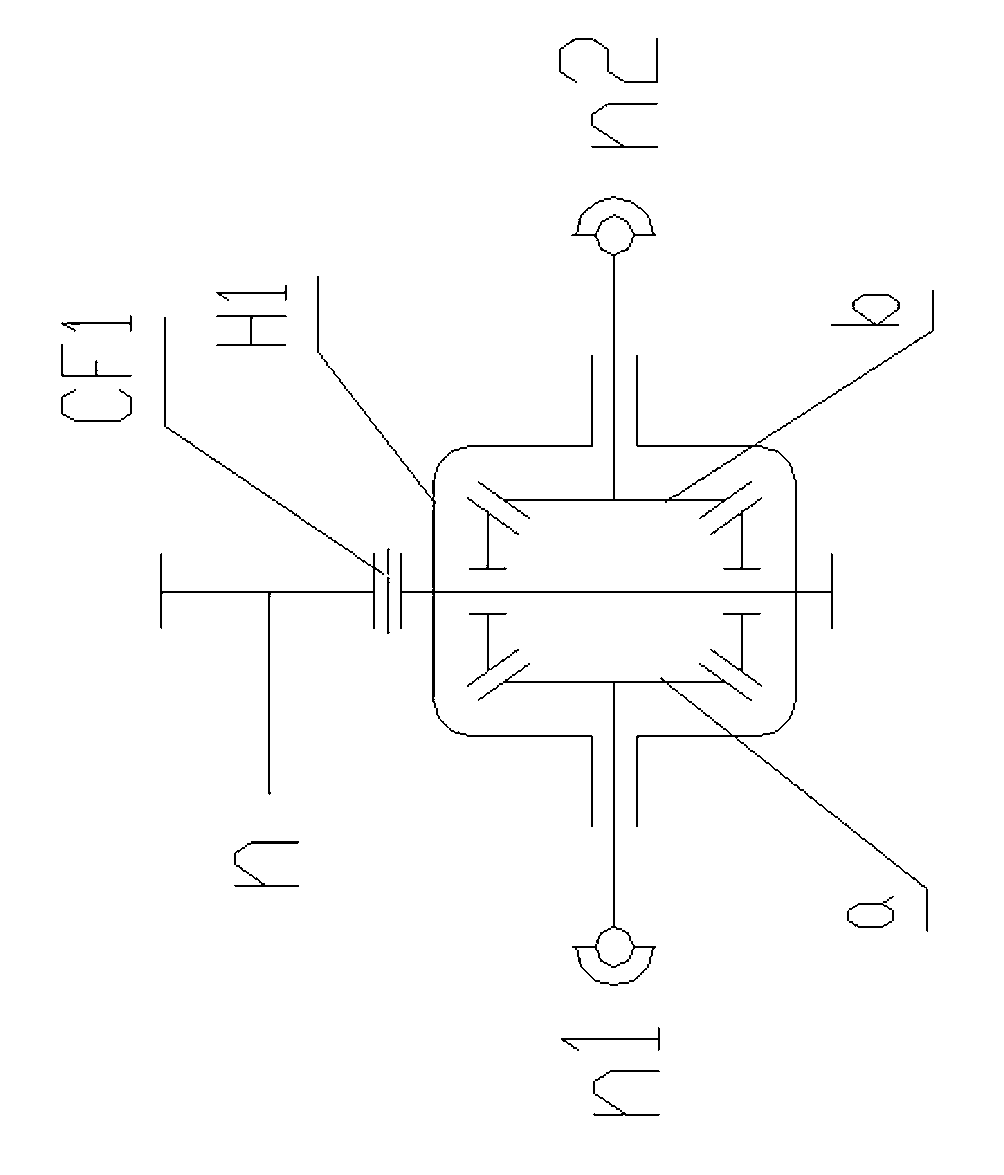

[0016] Such as figure 1 As shown, the engine power is input to the one-input-two-output transfer case assembly I after being shifted by the gearbox, and the planetary carrier H1 is driven by the gear pair CF1, and then the two side gears a and b are driven. The torque is divided into two outputs; one output is output through the drive shaft C1 to the one-input four-output differential transfer case II installed between the first and second axles, and the other is output through the drive shaft C2 to the 3. In the one-input four-output differential transfer case assembly II between the fourth bridge.

[0017] The torque input to the one-input four-output differential transfer case II installed between the first and second axles drives the planetary carrier H2 through the gear pair CF2, and then drives the side gear 1 and the side gear 2 , side gear 3, side gear 4; wherein, side gear 1 and side gear 2 have a mutual differential speed, and side gear 3 and side gear 4 have a mutu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com