High-equilibrium fly roll

A technology for balancing pressure and paper rollers, which is applied in the field of paper pressure rollers, and can solve the problems of unprocessable inner diameters and poor balance of pressure paper rollers, and achieve the effects of improving the phenomenon of overweight, facilitating processing, and consistent inner diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

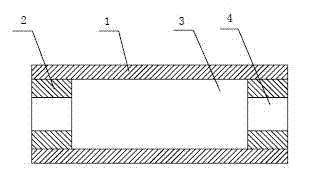

[0008] like figure 1 As shown, the high-balance platen roller includes a roller body 1 and a fixed bushing 2. The roller body is provided with an inner hole 3 along the axis, and the fixed bushing 2 is fixed on the inside of the two ends of the roller body 1. In the hole 3, an interference fit is adopted, and the middle part of the fixed shaft sleeve 2 is provided with a through hole 4 matched with the fixed shaft. Since the diameter of the inner hole 3 of the roller body 1 is consistent, the inner diameter 2 of the roller body 1 can be finished after the casting of the roller body 1, which can not only reduce the weight of the roller body 1 but also improve the problem of eccentricity of the roller body 1. Both ends are installed with fixed bushings 2 through interference fit, which are matched with the shaft to be installed. At the same time, the fixed bushings 2 are small in size and easy to process, and can well ensure that their own center of gravity does not shift, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com