Piercing needle semi-movable semi-fixed extrusion method

An extrusion method and piercing needle technology, which is applied in the semi-following and semi-fixed extrusion field of piercing needles, can solve the problems of lengthening the length of the ingot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

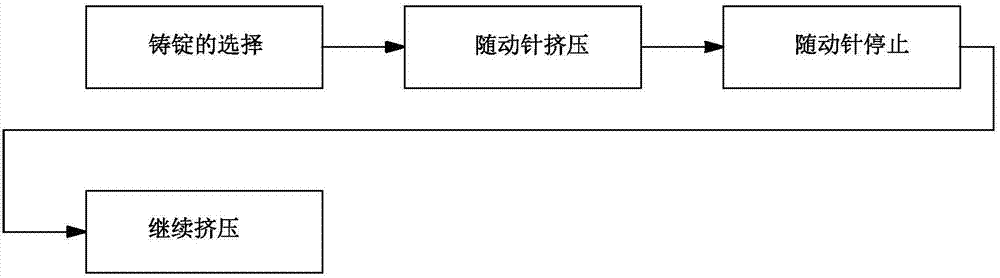

[0018] combine figure 1 As shown, a perforating needle semi-following semi-fixed extrusion method disclosed in this embodiment includes the following steps:

[0019] a. Selection of ingot: the length of the ingot is greater than 650mm;

[0020] b. Follower pin extrusion: select the follower pin as the piercing pin, move the selected ingot forward for a certain distance while keeping the follower pin relatively stationary, and then the follower pin stops moving;

[0021] c. The follower needle stops: After the follower needle moves a certain distance with the ingot, it remains fixed relative to the mold;

[0022] d. Continue to extrude: Since the follower needle remains still, the inner diameter of the product at the extruded position will remain the same.

[0023] Specifically, the moving distance of the follower needle in step b is 100mm-200mm.

[0024] Specifically, the follow-up speed in step b above is 0.2 mm / s.

[0025] Specifically, the extrusion temperature in step ...

Embodiment 2

[0028] Use a 25mn horizontal reverse double-action extrusion machine to extrude 7059 alloy. The extrusion specification is 140*5mm pipe. According to the tensile stress of the extrusion needle and the maximum pressure that the equipment can withstand, a semi-following and semi-fixed extrusion is adopted. Pressing method, adjust the follow-up distance to 150mm long, the ingot size used is φ252*132*650mm, the extrusion temperature is 400°C, the extrusion speed is 0.2mm / s; the diameter of the follow-up pin is 129mm at the head end, 131mm.

Embodiment 3

[0030] Use a 25mn horizontal reverse double-action extrusion machine to extrude 7059 alloy. The extrusion specification is 140*5mm pipe. According to the tensile stress of the extrusion needle and the maximum pressure that the equipment can withstand, a semi-following and semi-fixed extrusion is adopted. Pressing method, the ingot specification used is φ252*132*650mm, the extrusion temperature is 400°C, and the extrusion speed is 0.2mm / s. The maximum extrusion force in the entire extrusion is 24.5mn, and in the subsequent inspection process, the inner diameter of the pipe is 129 to 129.2 at the head end, and the mm tail end is 129.6 to 129.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com