Heating device for flat glass

A heating device, flat glass technology, applied in glass tempering, glass production, glass manufacturing equipment and other directions, can solve the problems of increased inner cavity pressure, large energy loss, increased glass production cost, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

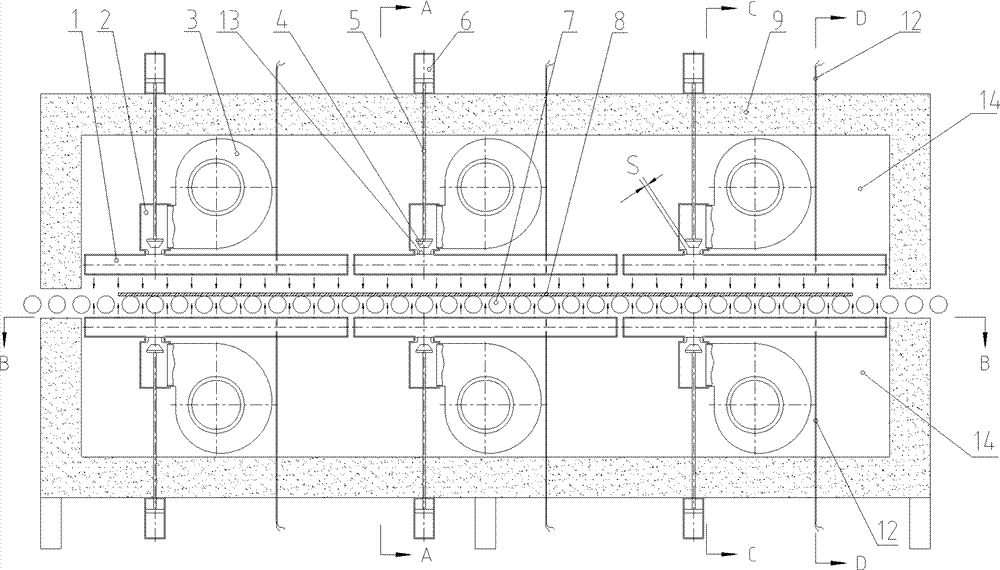

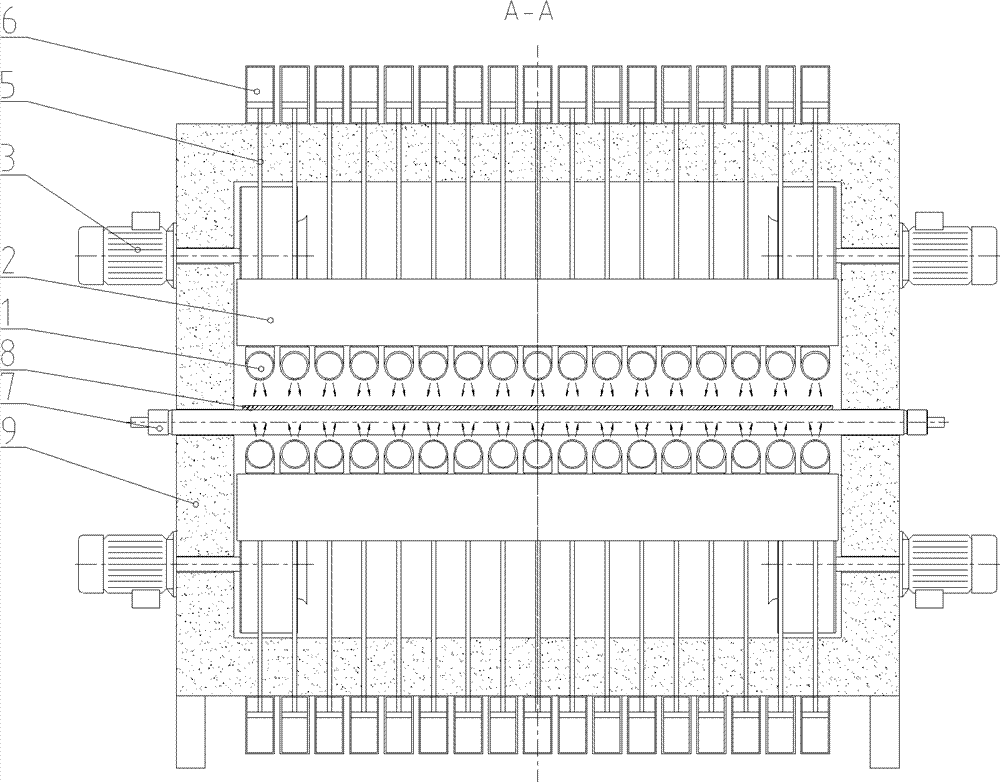

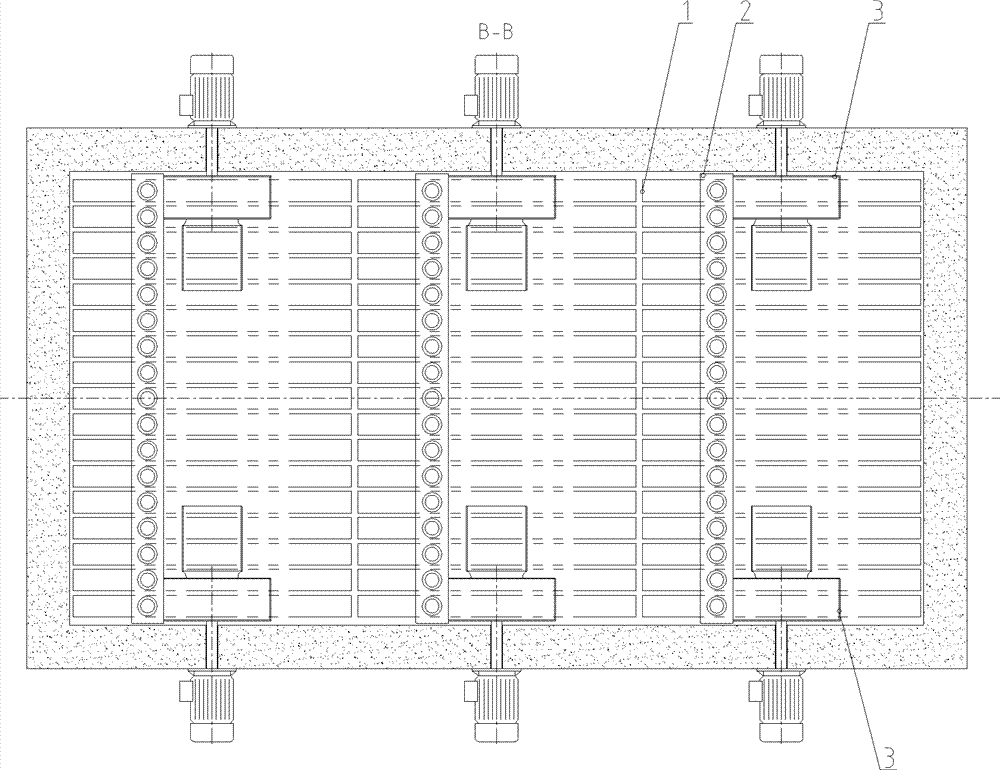

[0019] In order to better understand the shape, structure and characteristics of the present invention, preferred embodiments will be listed below and described in detail with reference to the accompanying drawings.

[0020] The core of the present invention is that the heating temperature inside the furnace cavity 14 is controlled by the temperature of the heater 11 arranged at the air inlet of the thermal circulation fan 3, and the temperature of each radiation convection tube 1 and the convective heating intensity to the glass 8 can be controlled by the inflow The high temperature gas flow rate (or pressure) in each tube is controlled. Each radiation convection tube 1 is arranged near the upper and lower surfaces of the glass 8 along the longitudinal direction (that is, the conveying direction of the glass), forming a continuous and uniform radiation convection belt to uniformly heat the entire upper and lower surfaces of the glass 8 .

[0021] Wherein, the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com