Heating device for casting wax

A heating device and heating tube technology, which can be used in casting molding equipment, lighting and heating equipment, heat exchanger types, etc., can solve problems such as uneven heating, and achieve the effects of simple structure, high efficiency, and uniform and continuous heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

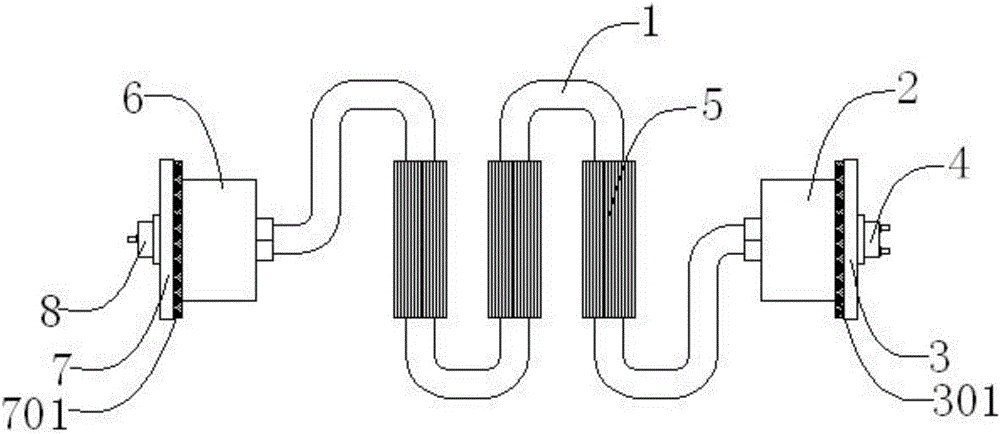

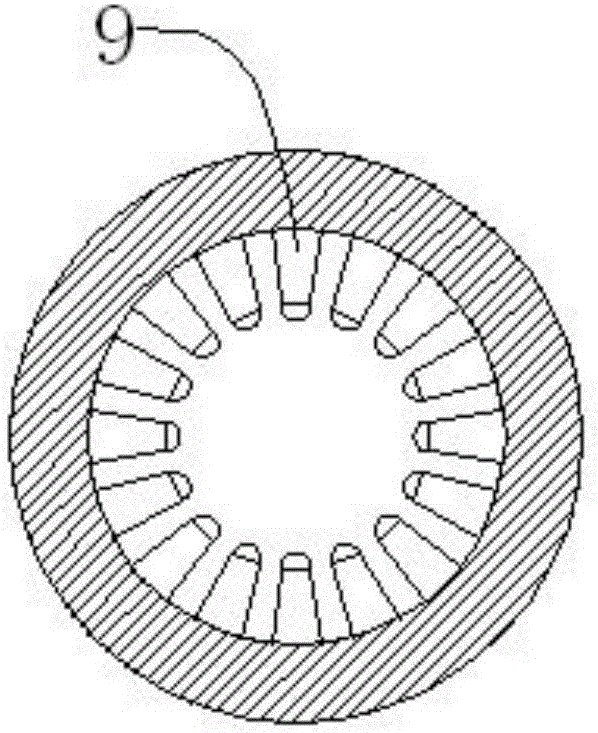

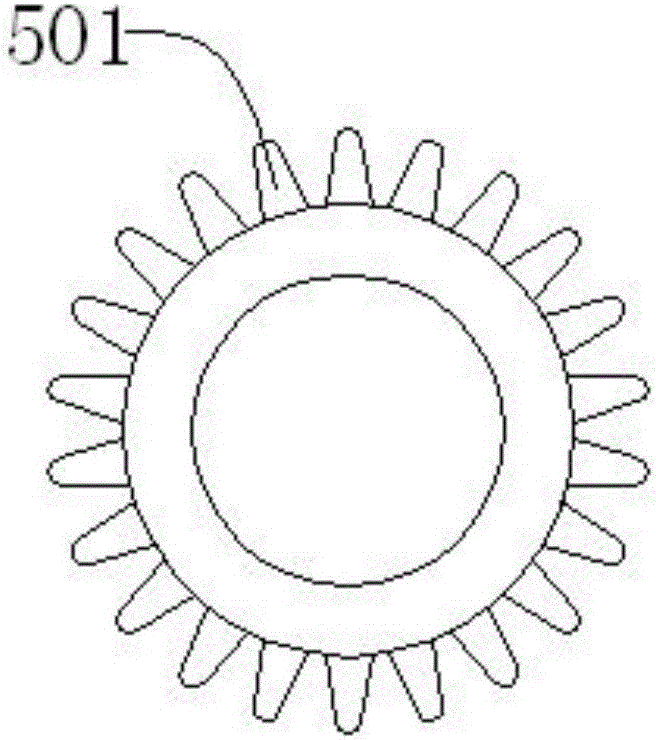

[0021] Such as figure 1 , figure 2 , image 3 As shown, a casting wax heating device includes a serpentine heat pipe 1, a first oil tank 2, a first cover plate 3, a heating pipe 4, no less than two radiators 5, a second oil tank 6, a second Cover plate 7, thermocouple 8, first fin 9, the first oil tank 2 is located on the right side of the serpentine heat pipe 1, the first oil tank 2 is threadedly connected with the serpentine heat pipe 1, and the first A cover plate 3 is located on the right side of the first fuel tank 2, the first cover plate 3 is threadedly connected with the first fuel tank 2, and one end of the heating pipe 4 passes through the first cover plate 3 and extends into the first fuel tank 2, so The heating pipe 4 is threadedly connected with the first cover plate 3 and is movably connected with the first oil tank 2, the radiator 5 is located outside the serpentine heat pipe 1, and the radiator 5 is closely matched with the serpentine heat pipe 1 connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com