Device and method for multi-stage layering sand prevention and well completion by one-step pipe column

A technology for pipe strings and sand control pipes, applied in the field of multi-stage layered sand control completion devices for one trip string, can solve the problems of increased risk, small well diameter, and difficulty in unsealing, so as to reduce the risk of later operations , The process operation method is simple, and the sealing effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

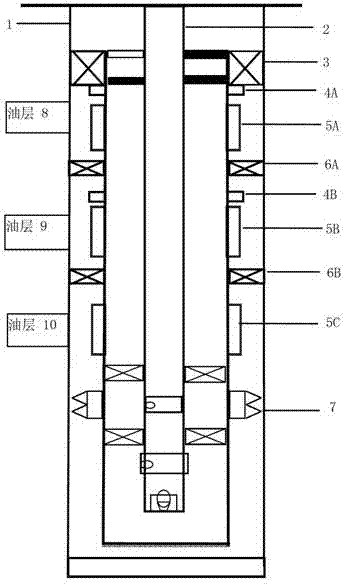

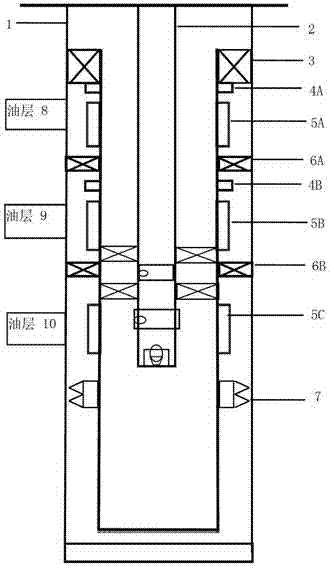

[0032] The multi-stage layered sand control completion device and method for one trip string of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

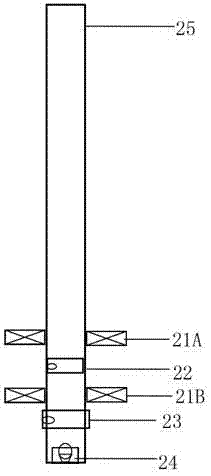

[0033] Such as figure 1 As shown, the multi-layer layered sand control completion device for one string of the present invention includes the oil layer casing 1 inserted into the first oil layer 8, the second oil layer 9 and the third oil layer 10 in sequence, and the oil layer casing 1 A blind pipe 11 is arranged inside, and the inside of the blind pipe 11 is provided with an integrated pipe string 2 for setting and sealing. Safety joint 4A, first sand control string 5A, first isolation packer 6A, second safety joint 4B, second sand control string 5B, second isolation packer 6B, third sand control string 5C and support slips 7. Wherein, the upper part of the integrated tubing string 2 for setting and sealing inspection is connected to the standard tubing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com