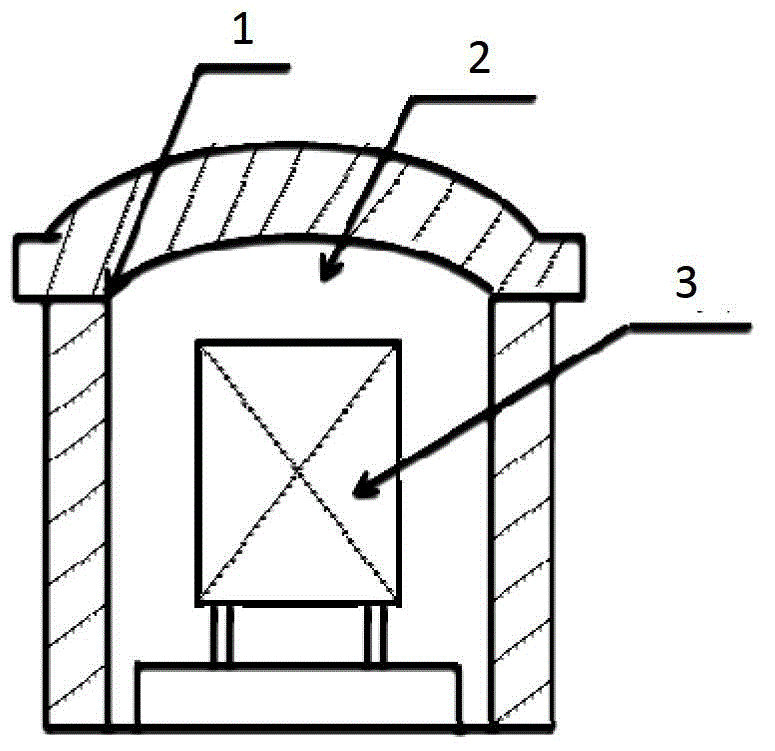

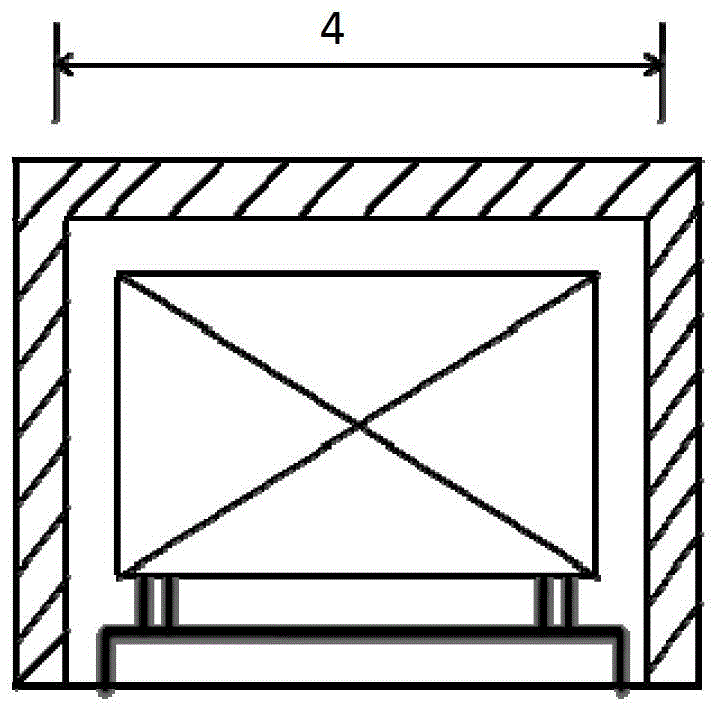

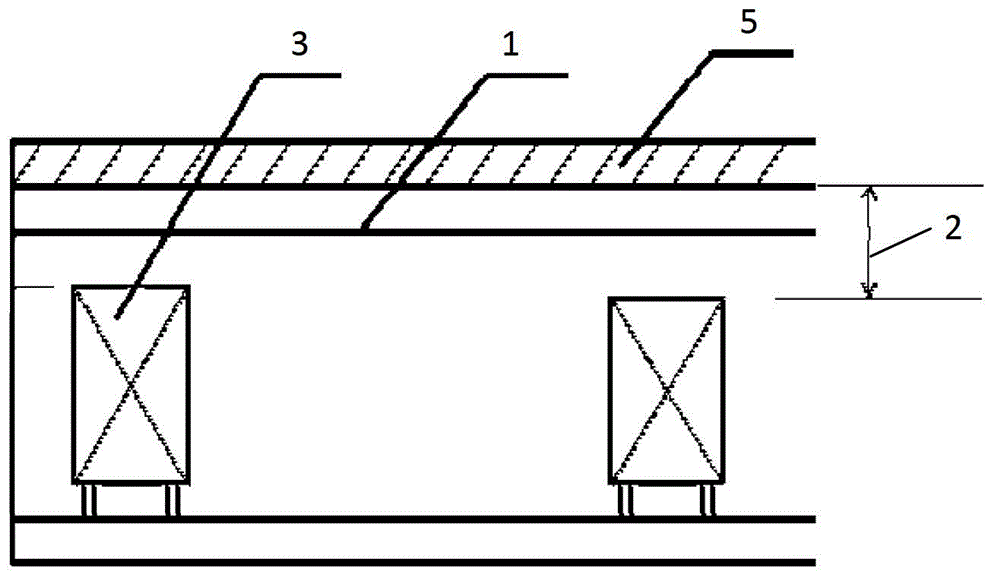

Large-section high-efficiency energy-saving type gas tunnel kiln

A tunnel kiln, large-section technology, applied in furnace types, furnaces, lighting and heating equipment, etc., can solve problems such as increasing energy consumption per unit product, extending the length of the cooling zone, reducing the driving speed, etc., to improve energy utilization efficiency, improve The effect of high firing quality and production thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0039] Example: Using the above plan to transform the existing 2 old 68.5-meter-long daily-use ceramic gas-fired tunnel kilns (with a section of 1 meter), and build a 68.5-meter-long and wide-section (1.8-meter) daily-use ceramic gas-fired tunnel kiln. After reconstruction, the production thermal efficiency of the tunnel kiln is ≥38%, and the annual energy saving of a single kiln is equivalent to 915.3 tons of standard coal, which is 29.3% more energy-saving than the original tunnel kiln. In addition, the wide-body tunnel kiln has the advantages of "high production thermal efficiency, multi-variable coupling intelligent control, fast system response, convenient operation of the whole machine, and suitable for high-temperature combustion", which is conducive to improving the qualified rate of firing products and improving the firing quality of products , Produce more high-end products.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap