Differential pressure switch

A differential pressure switch, switch contact technology, applied in electrical switches, electrical components, circuits, etc., can solve problems such as connection problems, functional failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

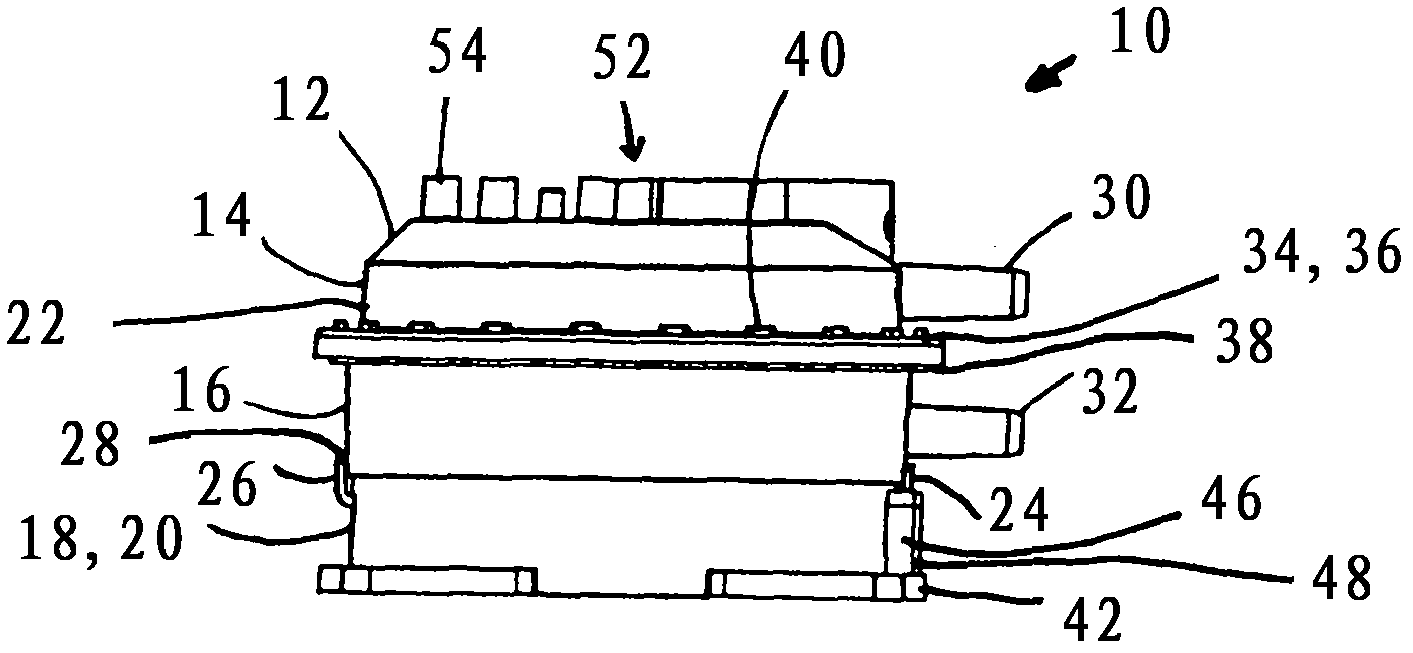

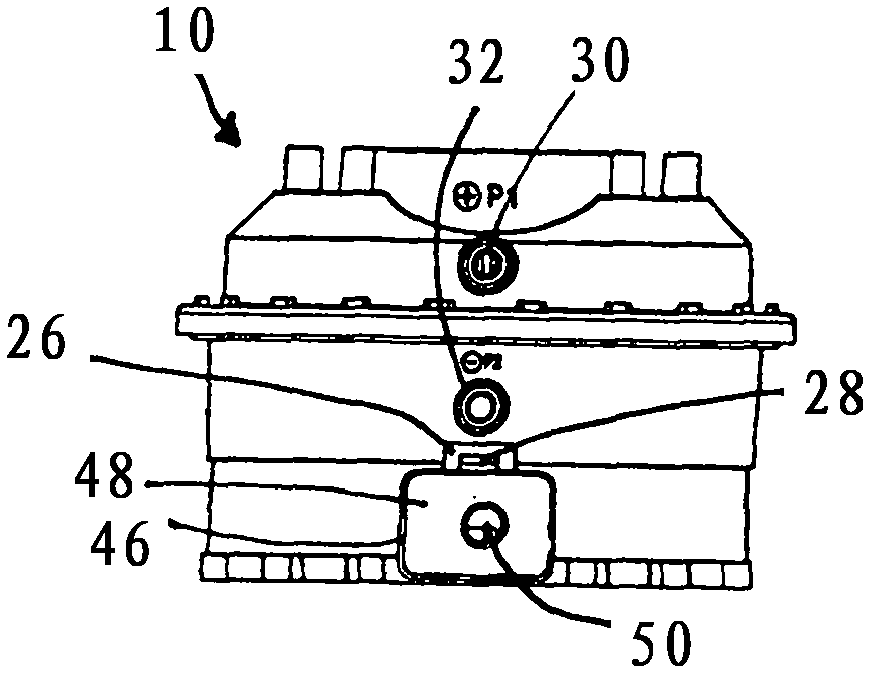

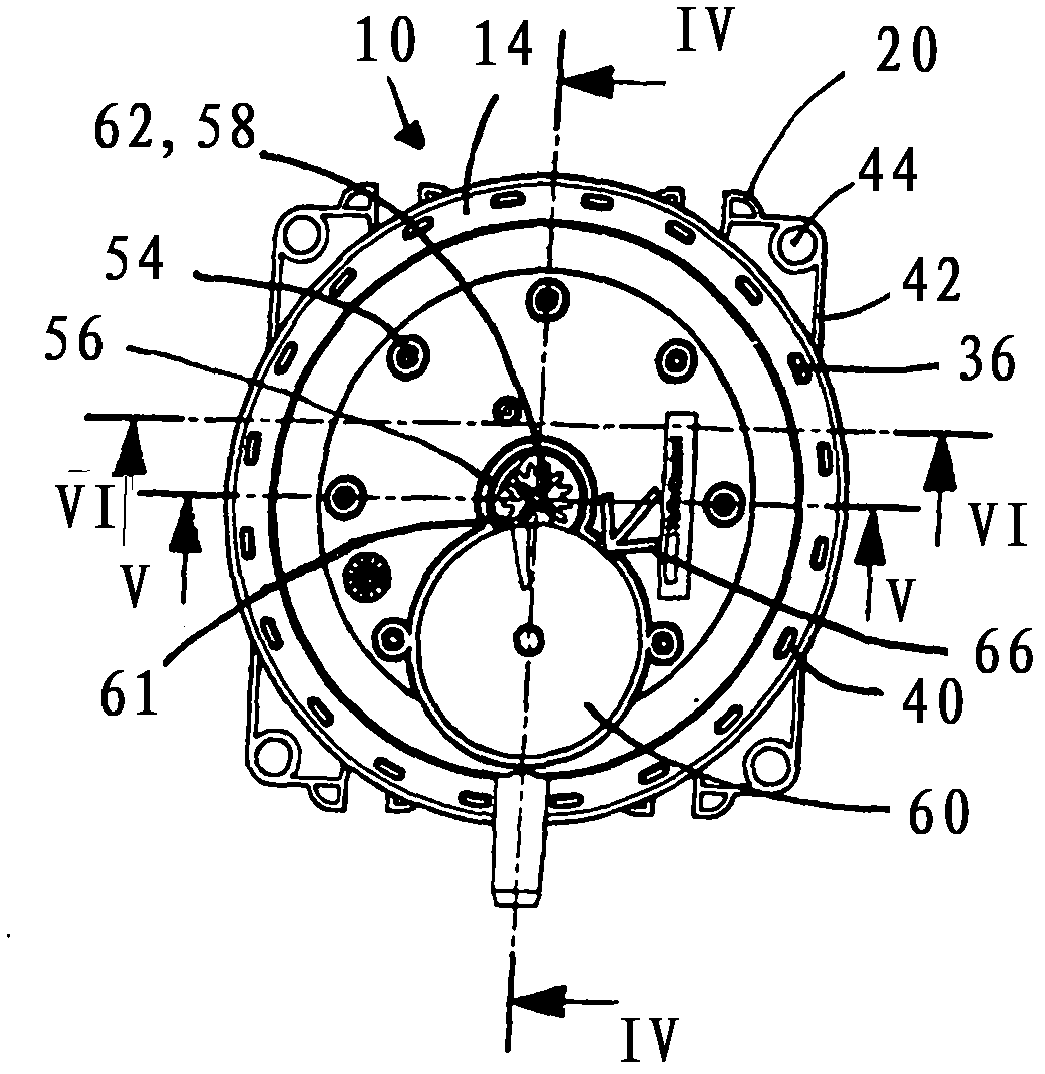

[0063] figure 1 A side view of a differential pressure switch 10 is shown. The housing 12 comprises a first housing part 14 , a second housing part 16 and a third housing part 18 which at the same time forms the base 20 . The first housing part 14 and the second housing part 16 together form a structural unit 22 which is attached to the third housing part 18 by means of a snap connection 24 . The first and second housing members 14, 16 jointly define an interior cavity 25 (see Figure 4 ). The snap-in connection 24 has two opposite jaws 26 which are formed on the third housing part 18 . These lugs 26 hook onto correspondingly shaped and provided projections 28 formed on the second housing part 16 . The snap-fit connection 24 can be detached by pushing apart the clamping plates 26 in a direction away from the third housing part 18 .

[0064] The first housing part 14 has a first pressure connection 30 and the second housing part 16 has a second pressure connection 32 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com