Fuel cell stack capable of being started at low temperature and operated at high temperature

A fuel cell stack, high temperature operation technology, used in fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of polluted electrodes, unusable, easy leakage of cooling fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

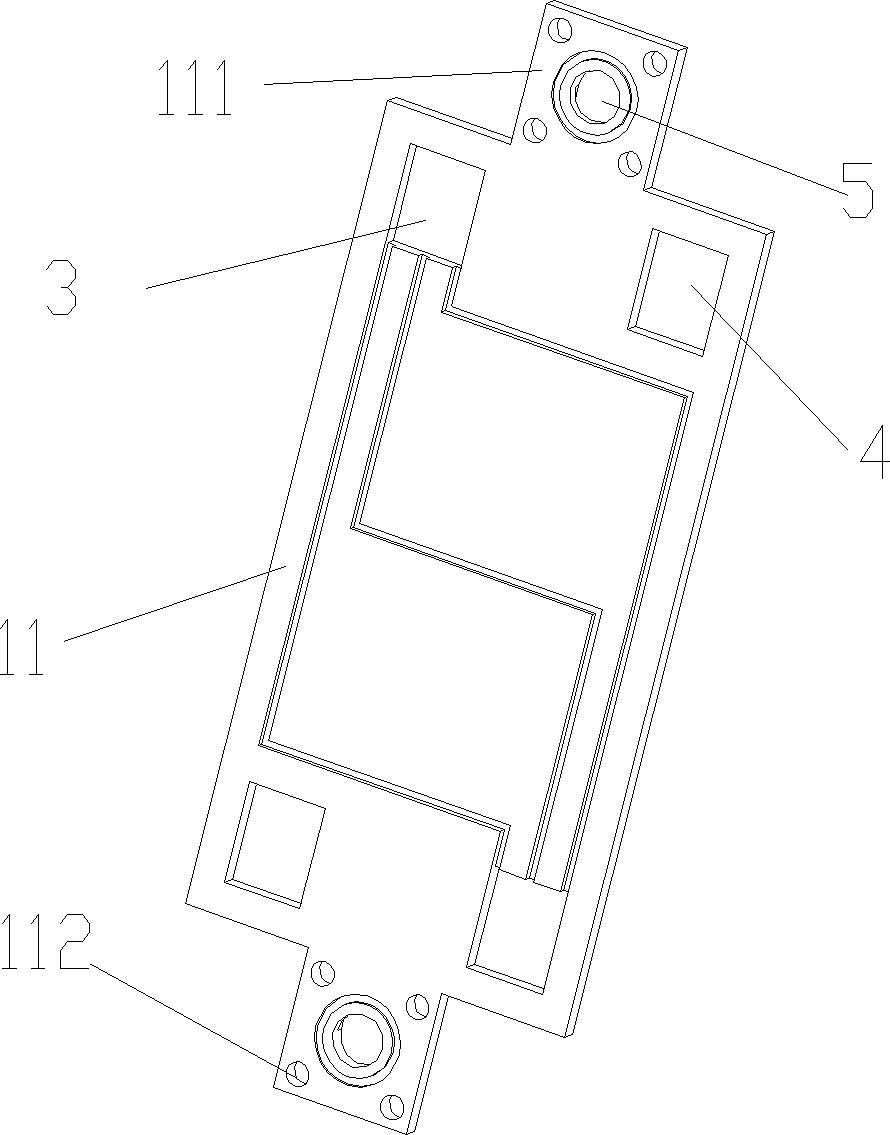

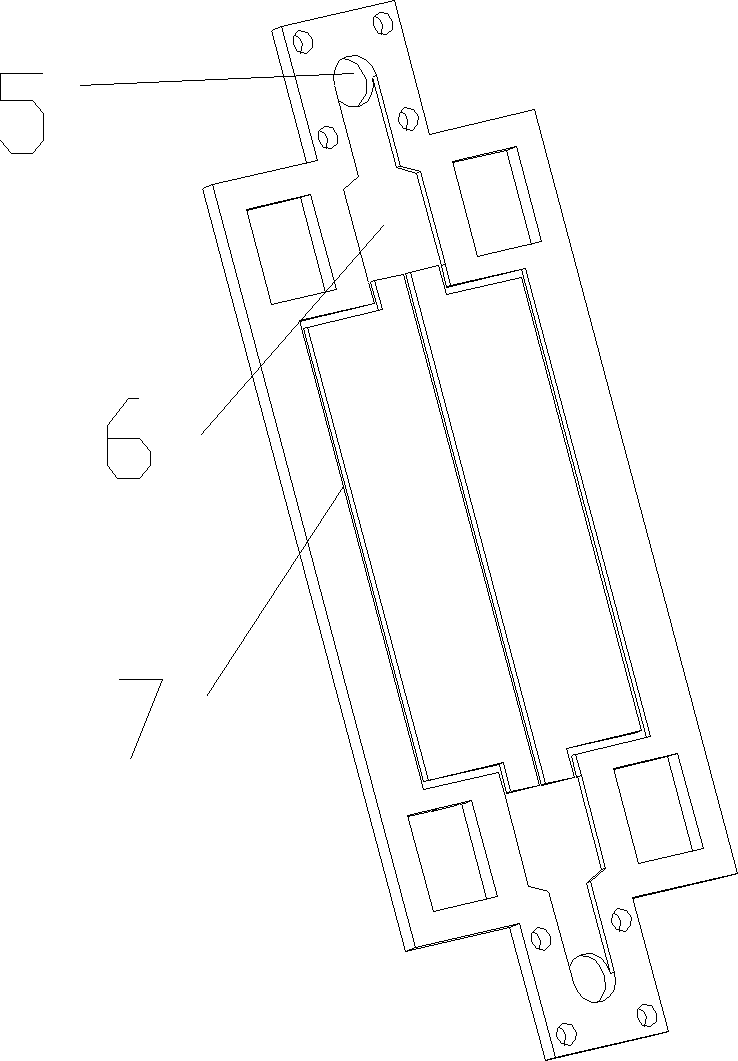

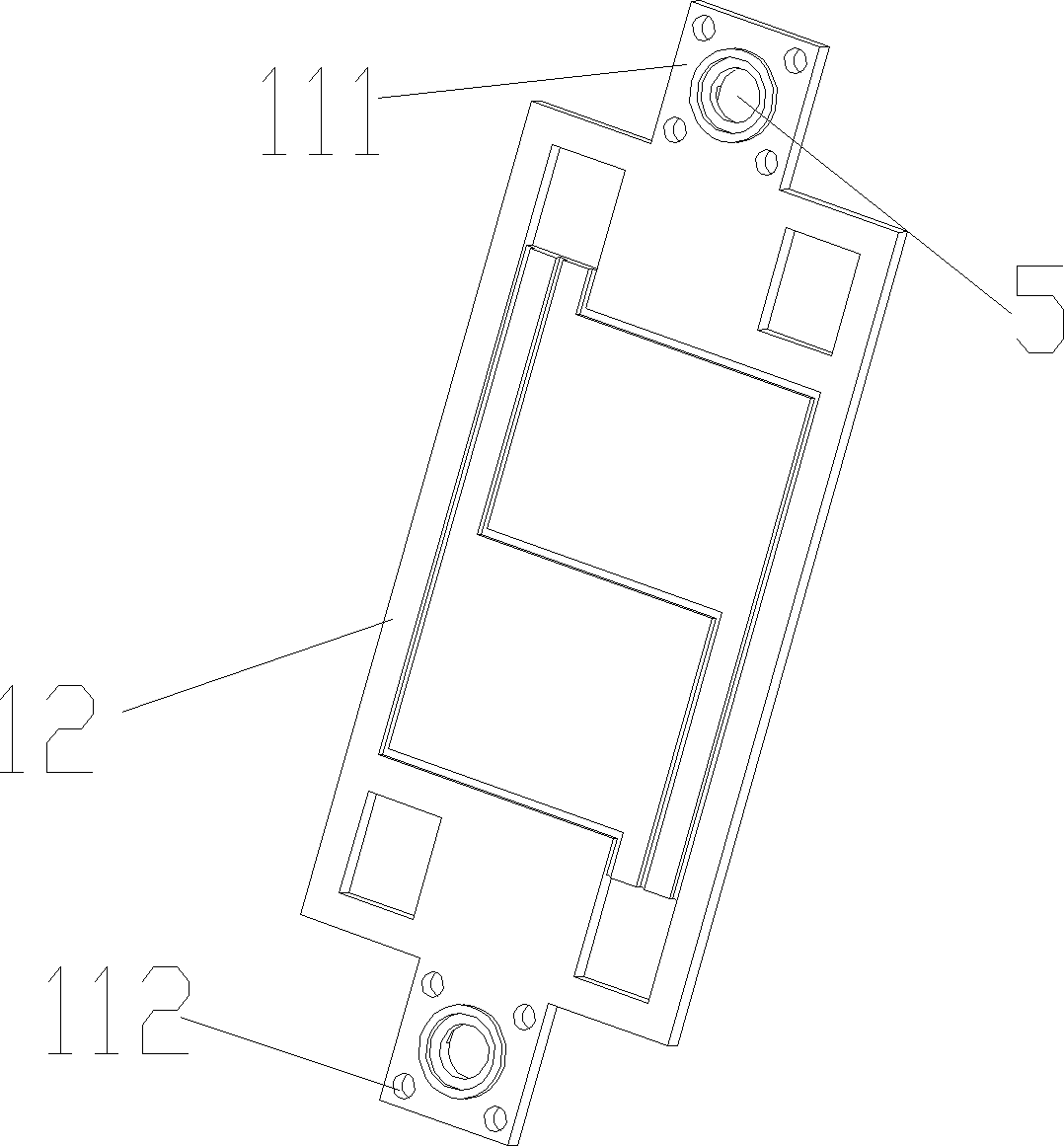

[0032] Such as Figure 1-9As shown, a fuel cell stack capable of starting at low temperature and operating at high temperature includes a deflector, electrodes, a front end plate, and a rear end plate. , its size length × width × thickness is 400mm × 100mm × 2.5mm (such as Figure 5 shown) and ordinary bipolar plate, its size length × width × thickness is 400mm × 100mm × 1.2mm (such as Image 6 shown), the described flow-guiding bipolar plate 1 with a cooling fluid groove includes a front-guiding airflow groove plate 11 (such as Figure 3-4 Shown), reverse side hydrogen guide air flow groove plate 12 (as Figure 1-2 Shown), the air-guided flow channel plate 11 and the hydrogen-guided air flow channel plate 12 are bonded to form a cooling fluid interlayer in the middle, and the air-guided flow channel plate 11 is provided with an air inlet and outlet fluid hole 3, a hydrogen inlet and outlet fluid hole 4, and The guide groove connecting the air in and out of the fluid hole, ...

Embodiment 2

[0040] see Figure 1-6 The flow-guiding bipolar plate with the cooling fluid groove and the common bipolar plate can also be of other shapes and sizes, and the flow-guiding bipolar plate with the cooling fluid groove can extend a protrusion in the middle, or two The end extends out of the protrusion, and a cooling fluid inlet and outlet hole is provided. Two or three ordinary bipolar plates can be arranged between two adjacent flow-guiding bipolar plates with cooling fluid grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com