Preparation method of catalyst for direct methanol fuel cell and direct methanol fuel cell

A methanol fuel cell and catalyst technology, applied in the field of electrocatalysis, can solve problems such as unfavorable large-scale synthesis and complicated operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a catalyst for a direct methanol fuel cell, including the following steps:

[0031] a) Redox reaction of carbon substrate and potassium permanganate in water to obtain carbon-based catalyst carrier;

[0032] b) Mixing the carbon-based catalyst carrier obtained in the step a) and the active material precursor, and after the reaction, the catalyst for the direct methanol fuel cell is obtained.

[0033] In the present invention, the carbon substrate and potassium permanganate are used as raw materials, and the redox reaction is carried out in the water phase to realize the modification of the carbon substrate and obtain the carbon substrate catalyst carrier.

[0034] In the present invention, it is preferable to first disperse the carbon substrate in water to obtain a suspension of the carbon substrate; then add potassium permanganate to the suspension of the carbon substrate to perform the oxidation-reduction reaction to obtain a carbo...

Embodiment 1

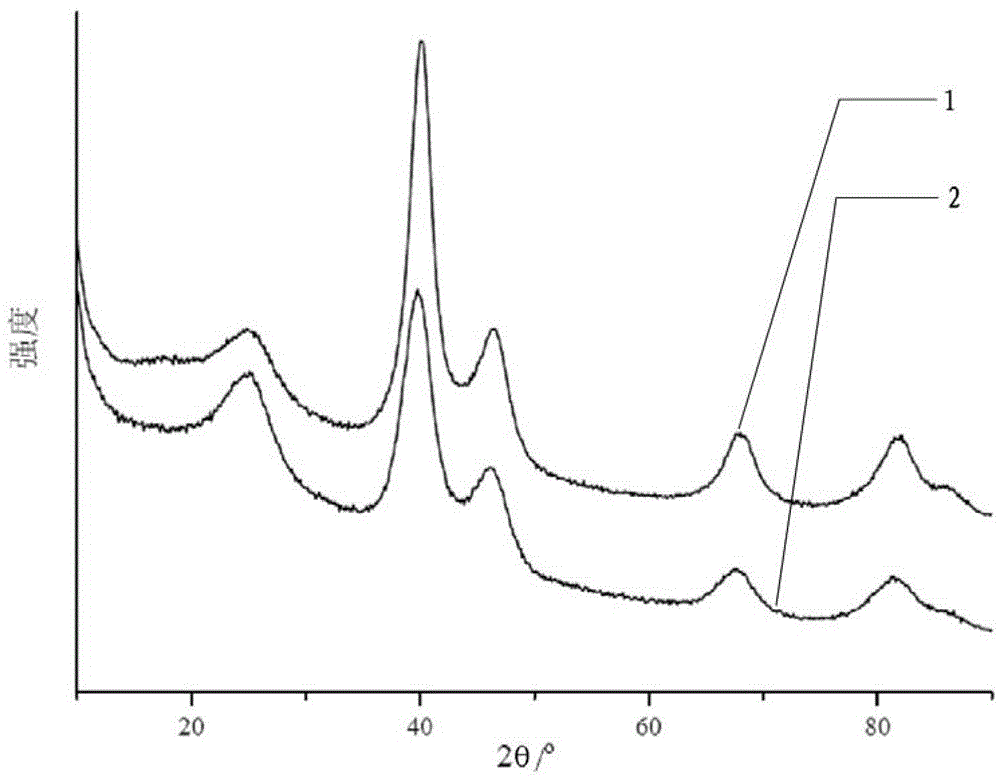

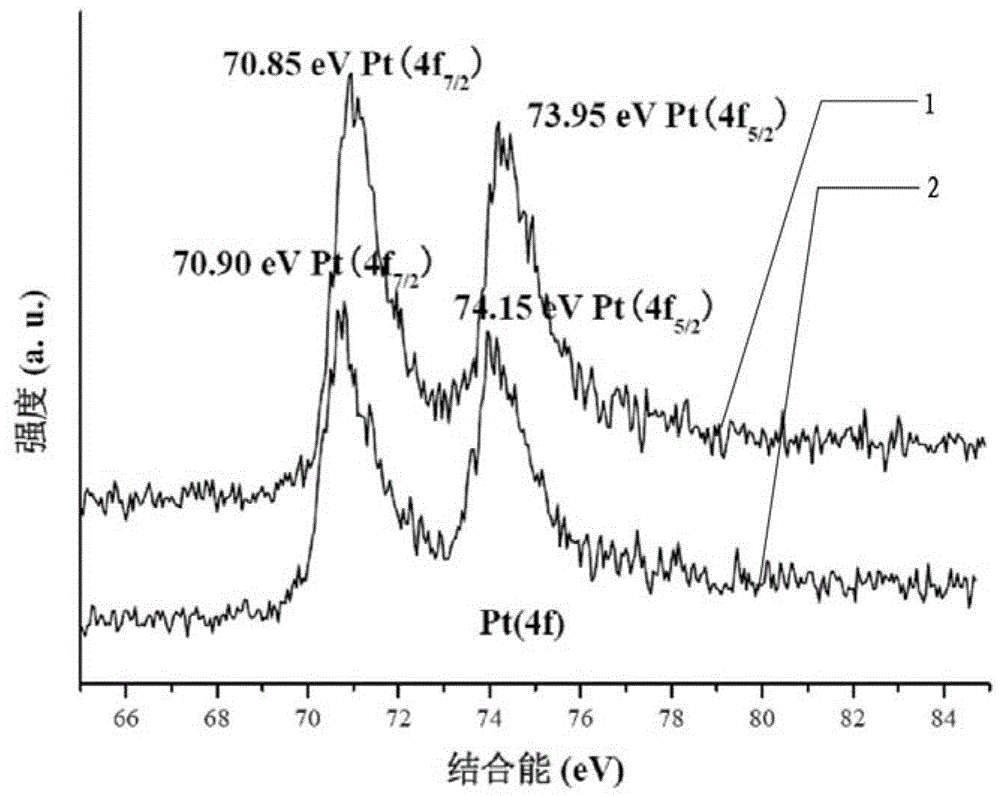

[0061] Disperse 80 mg of conductive carbon black of model Vulcan XC-72R in 200 mL of deionized water by ultrasound to obtain a dispersion of conductive carbon black. The resistivity of the deionized water is 18.2 MΩ·cm. 1.4mg KMnO is added to conductive carbon black 4 , And react for 6h under stirring to obtain a carbon-based catalyst carrier.

[0062] After the above reaction is completed, add 1.105 mL of a chloroplatinic acid aqueous solution with a mass concentration of 18.105 mgPt / mL to the resulting reaction solution, and after stirring for 4 hours at room temperature, dropwise add NaBH with a mass concentration of 1 mg / mL to it. 4 After stirring the solution for 5 hours, the obtained reaction solution was suction filtered and washed with deionized water. The resistivity of the deionized water was 18.2MΩ·cm, and it was suction filtered until there was no Cl - Exist, the final solid was vacuum dried at 80°C to obtain platinum-supported carbon-based catalyst carrier, that is, a ...

Embodiment 2

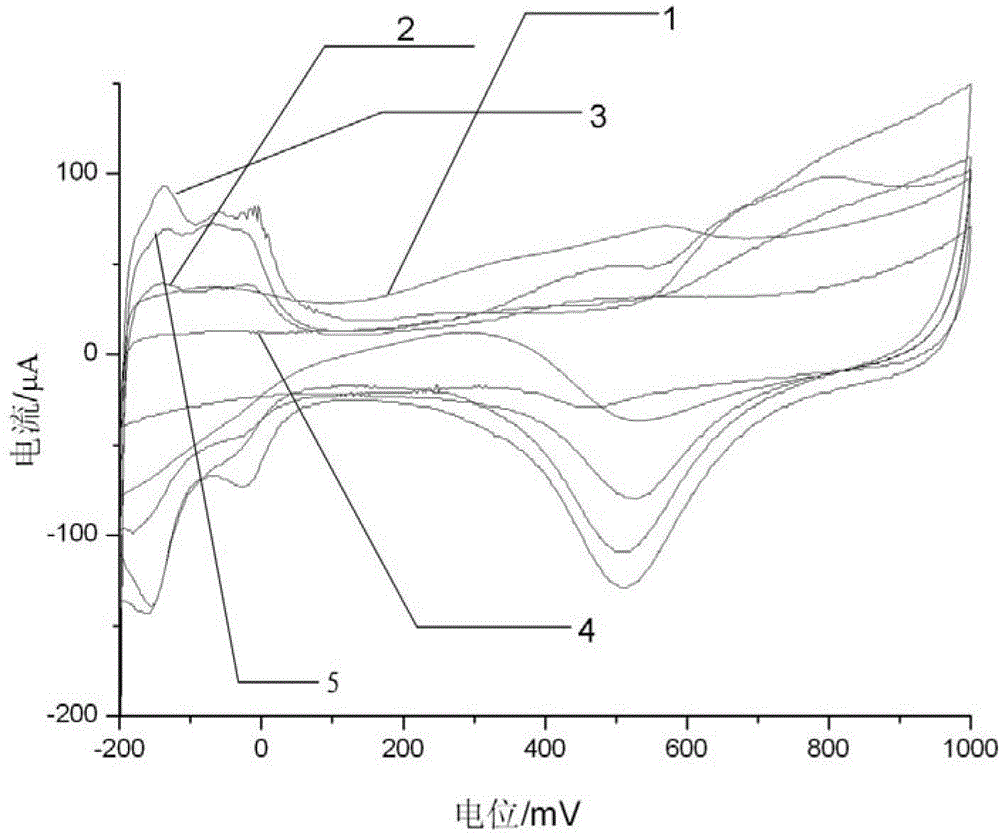

[0070] Take 80mg of conductive carbon black model Vulcan XC-72R and 2.7mg KMnO 4 As a raw material, a carbon-based catalyst support was obtained according to the method described in Example 1, and catalytic platinum was deposited on the carbon-based catalyst support according to the method described in Example 1, to obtain a catalyst for a direct methanol fuel cell. The obtained 5 mg of catalyst was added to 50 μL of Nafion solution and 1 mL of ethanol for ultrasonic dispersion for 30 minutes to obtain a dispersion solution of the catalyst; 10 μL of the dispersion solution of the catalyst was dripped on the glassy carbon electrode and dried at room temperature to obtain a modified electrode.

[0071] The modified electrode is used as the working electrode, the Ag / AgCl electrode is used as the reference electrode, the Pt sheet is used as the counter electrode, and the three-electrode system is used to remove oxygen with a molar concentration of 0.5 mol / L H 2 SO 4 Carry out cyclic vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com