Method for drawing and forming wide flange panel-shaped parts

A flange face and flange technology, which is applied in the field of drawing forming of wide flange panel parts, can solve the problems of part cracking, failure to form, and influence on material flow, etc., and achieve the effect of sufficient forming and rigidity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

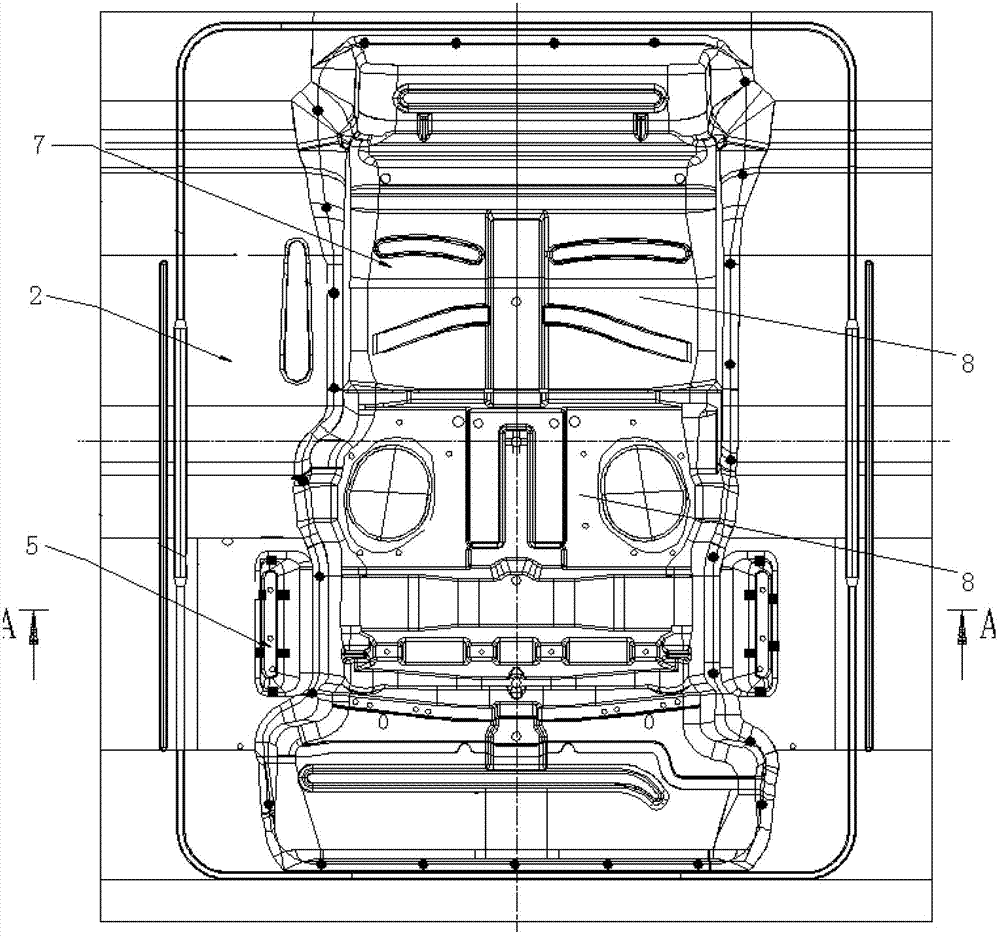

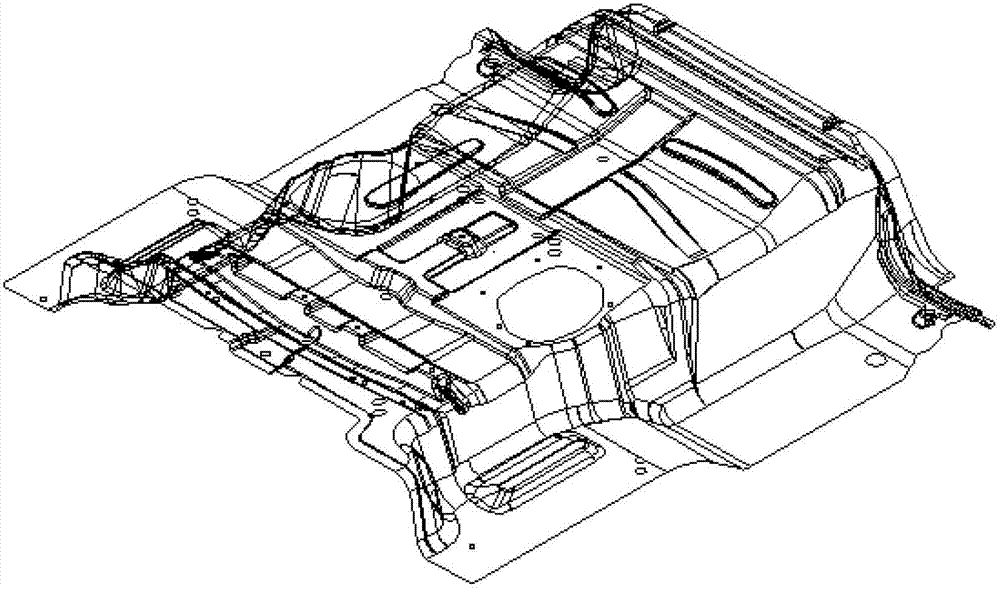

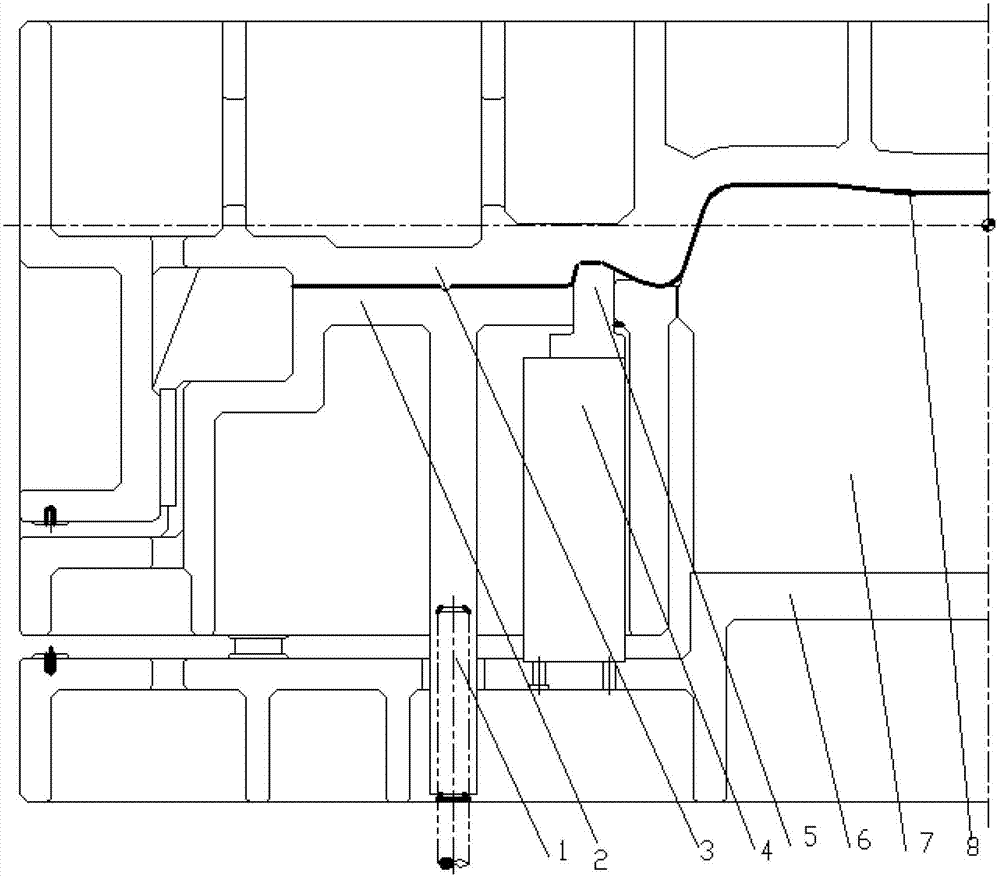

[0018] In this embodiment, there are two rectangular convex hulls of 300*120*30 on the flange surface of the wide flange panel-shaped workpiece. When drawing, the upper part of the wide flange panel-shaped part 8 is the upper mold, and the lower part is the lower mold. , the punch insert 5 is fixed on the punch insert holder 4 of the lower template, and the drawing punch 7 is fixed on the drawing punch holder 6. When working, the ejector rod 1 lifts the blank holder 2, and the top With a height of 250mm (effective working stroke 240mm), the drawing die 3 goes down and begins to stretch. When the stretch is 210mm and 30mm away from the end of forming, the punch insert 5 at the bottom starts to work, and the shape of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com