Electric mechanism riveting mould

An electrical and riveting technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of long riveting time, increased labor cost, poor consistency and standardization of operating procedures, etc., to reduce labor The cost of expenditure, the effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

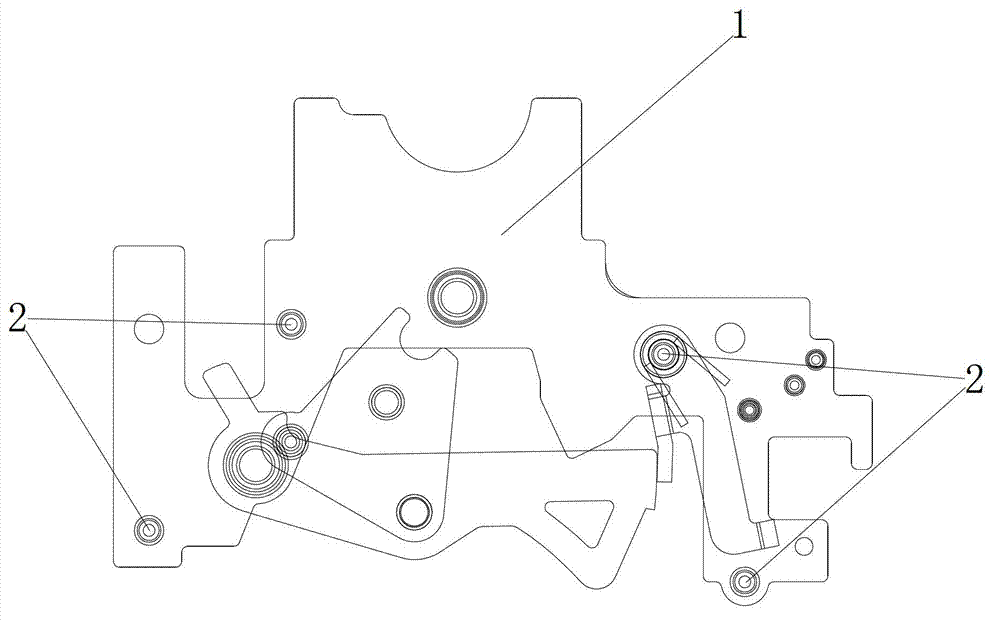

[0016] attached figure 1 It is a structural schematic diagram of an electric mechanism in the prior art, which has four connecting shafts 2, and the shaft ends of the connecting shafts 2 are connected to the electric mechanism 1 by riveting.

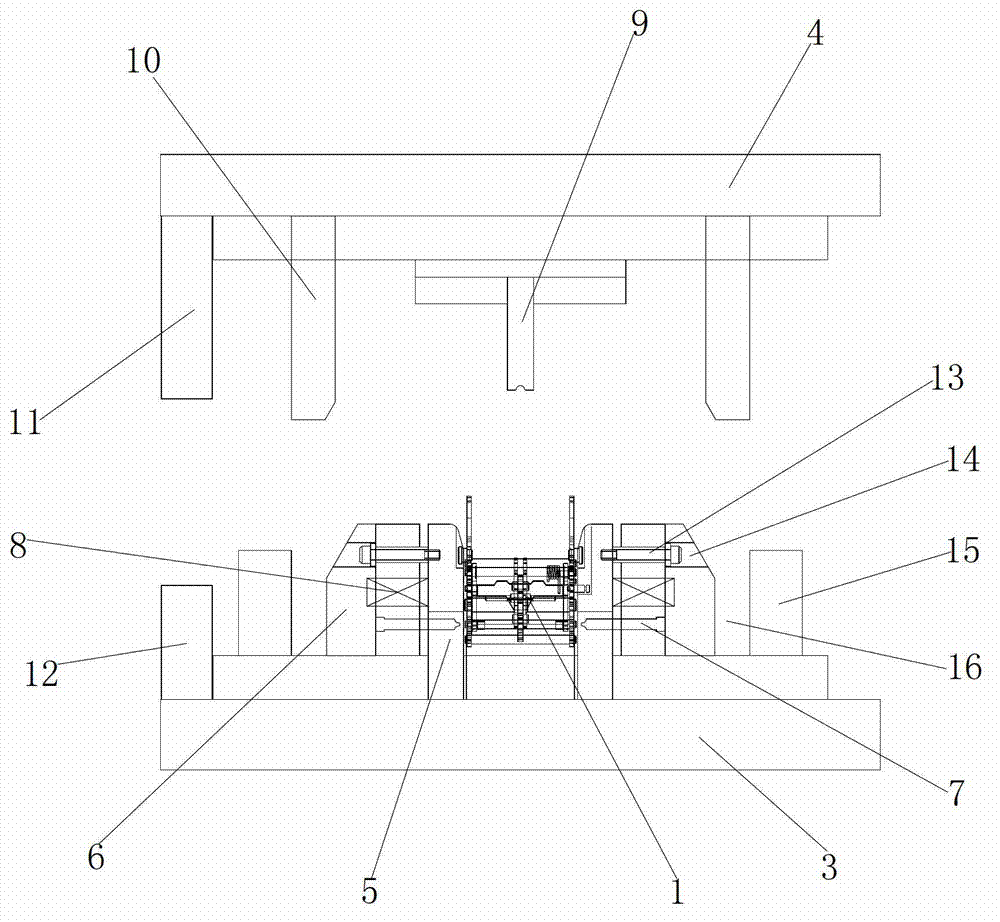

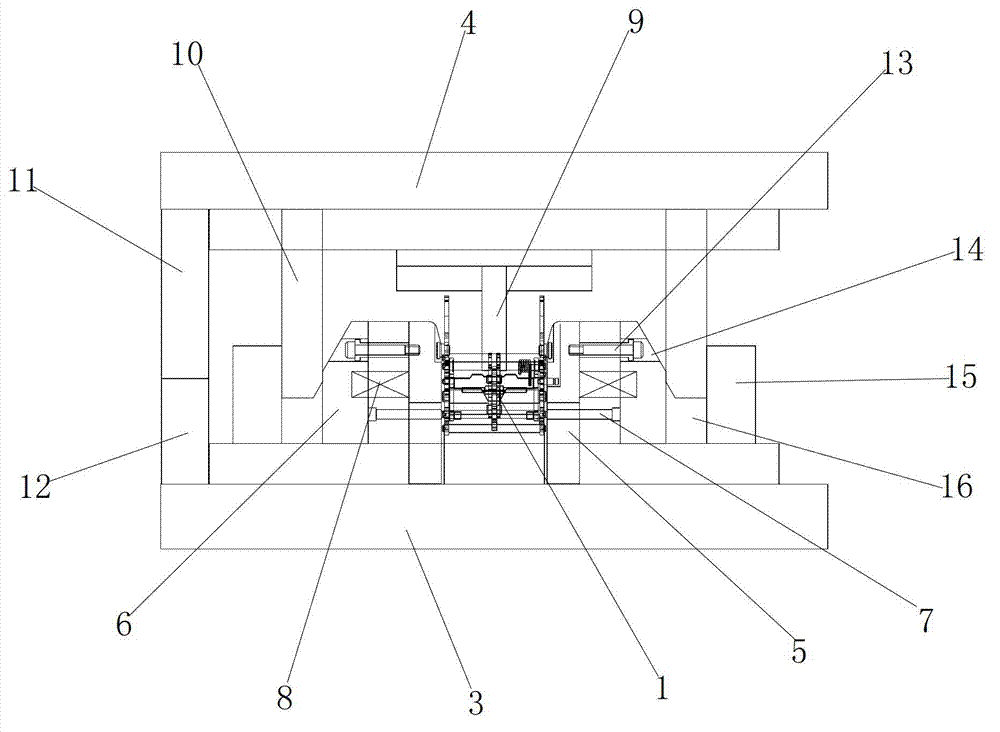

[0017] attached figure 2 , 3 It is a kind of electric mechanism riveting die described in the present invention, comprises bottom mold base 3 and the upper mold base 4 used in conjunction with it; Bottom mold base 3 is provided with electric mechanism positioning block 5, and electric mechanism positioning block 5 has four groups , which are respectively vertical plate-shaped bodies and in a rectangular array on the middle part of the bottom mold base 3, the electrical mechanism 1 is installed on the four sets of electrical mechanism positioning blocks 5, and the two sets of electrical mechanism positioning blocks 5 on the opposite side are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com