Material level structure of screw workpiece composite washers

A technology of composite gaskets and parts, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult hooks and process obstacles, and achieve the effects of accurate and smooth fitting, improved production efficiency, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

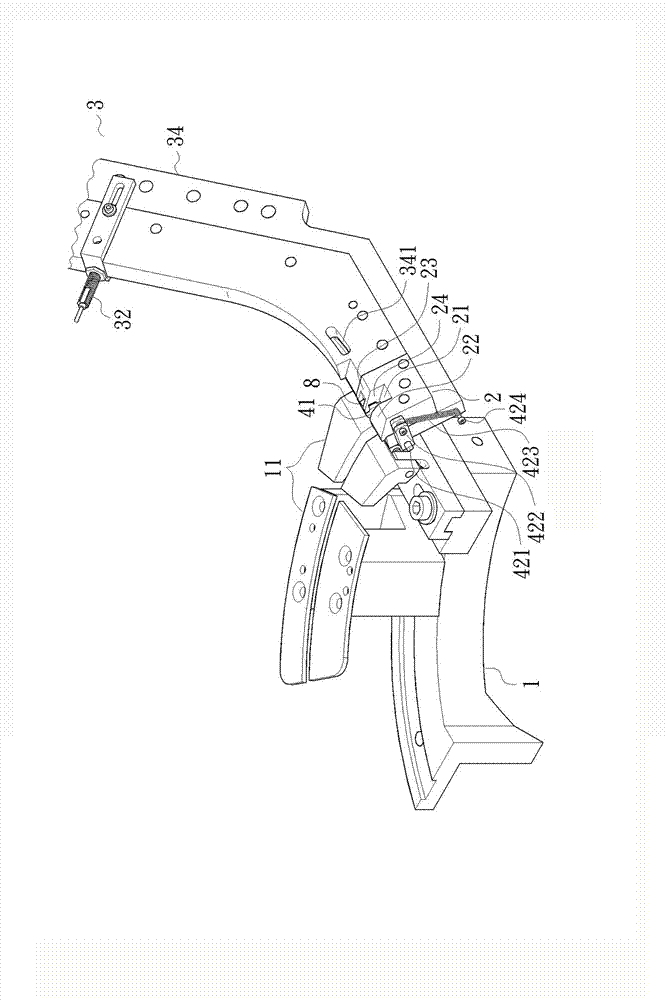

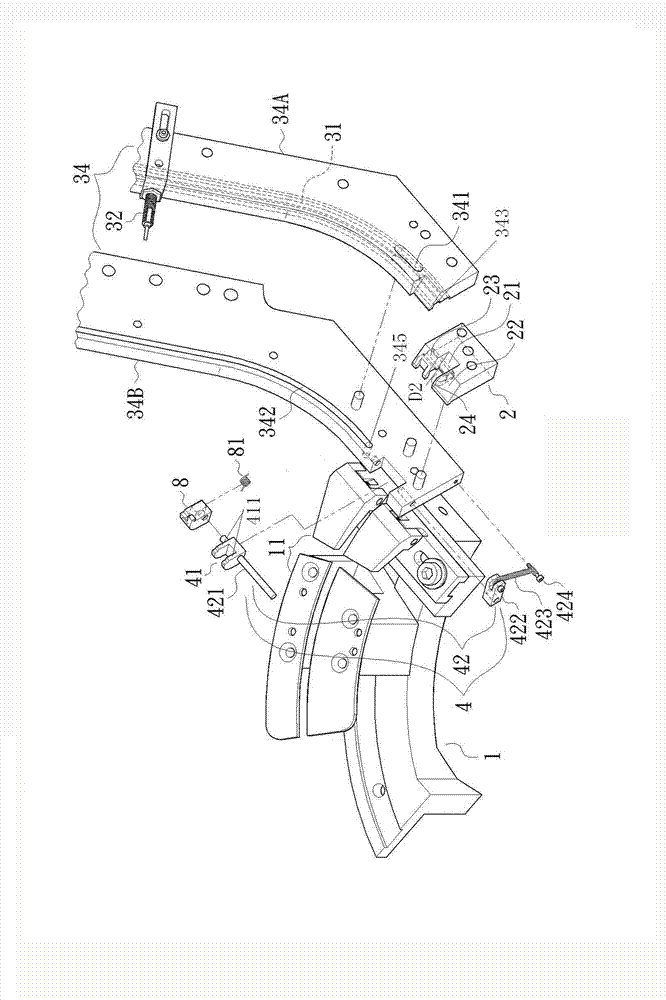

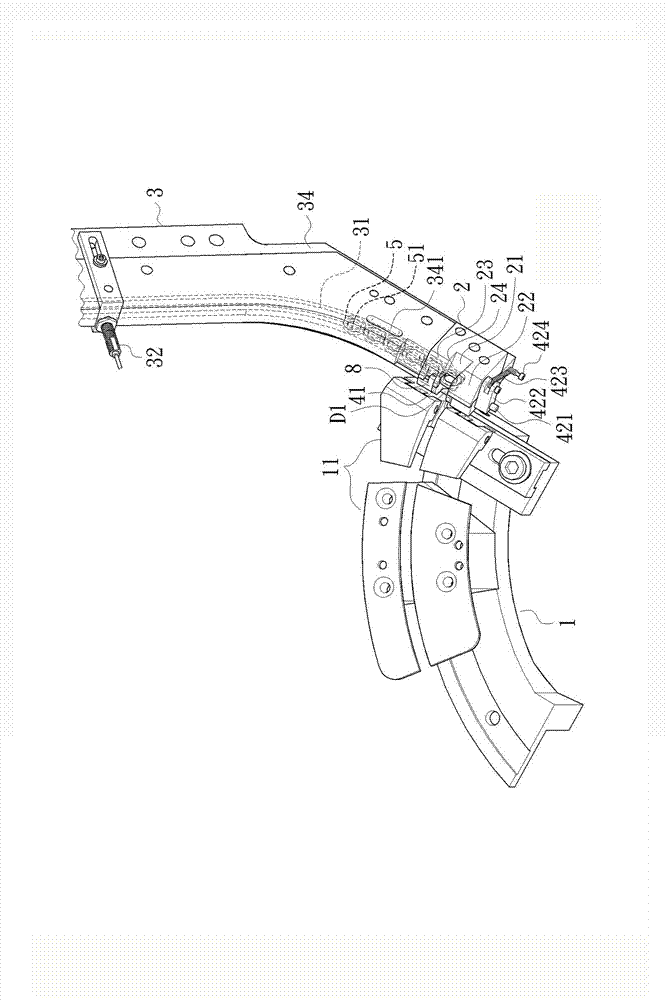

[0015] The content, characteristics and embodiments of the present invention are described below with the help of drawings.

[0016] In the figure, 1 is the machine body, 11 is the track, 2 is the feeding mechanism, 21 is the bottom wall, 22 is the first side wall, 23 is the second side wall, 24 is the screw channel, 3 is the guide rail, 31 is the rail groove , 32 is a detection device, 34 is a frame body, 34A is a first rail flap, 34B is a second rail flap, 341 is a window hole, 342 is a first strip groove, 343 is a second strip groove, 345 is a through hole, 4 is a rear contact mechanism, 41 is a first rear contact block, 411 is a rear contact surface, 42 is an elastic mechanism, 421 is a linkage rod, 422 is a pull lever, 423 is a spring, and 424 is a fixed rod , 5 is a washer, 51 is an annular hole, 6 is a screw workpiece, 7 is a pressing plate, 8 is a second back block, and 81 is an elastic assembly.

[0017] The invention relates to a material position structure of a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com