Pneumatic tire molding method and molding apparatus

A technology of pneumatic tires and tires, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of surface deformation and sticking difficulties of sidewall parts, and achieve the effect of reliable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

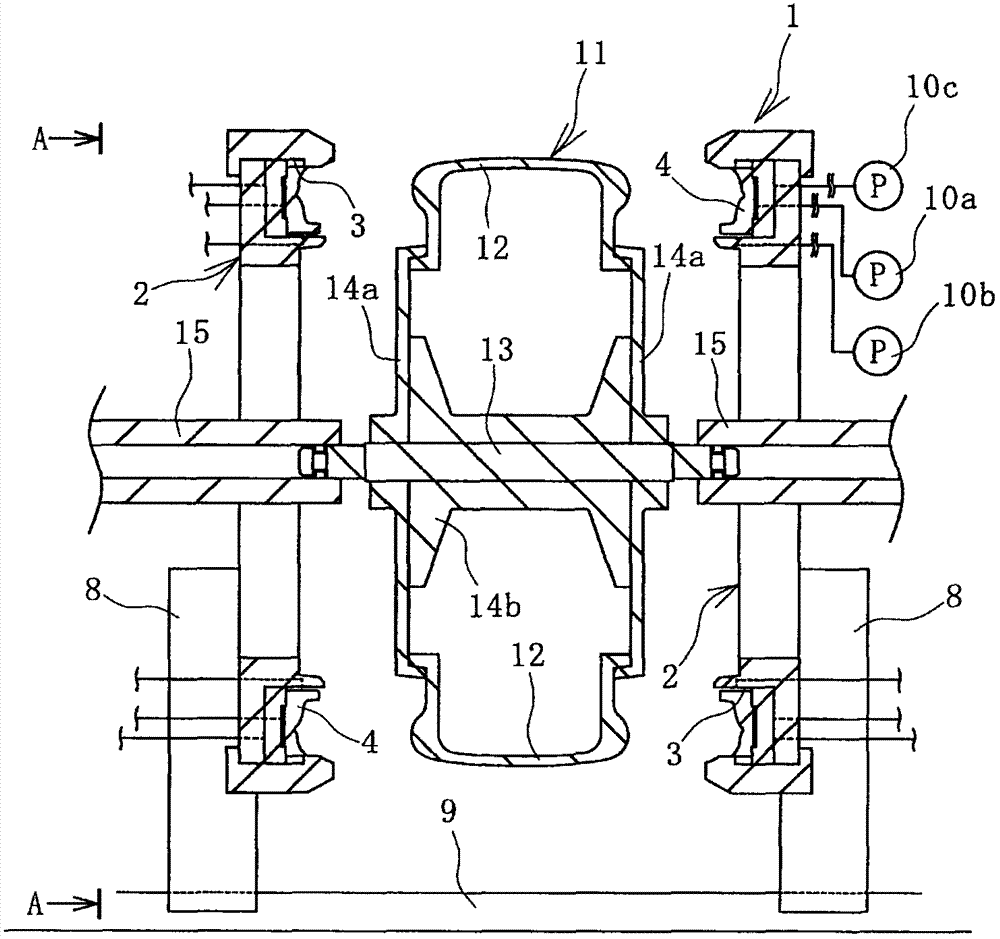

[0048] Hereinafter, the method and apparatus for forming a pneumatic tire of the present invention will be described based on the illustrated embodiment.

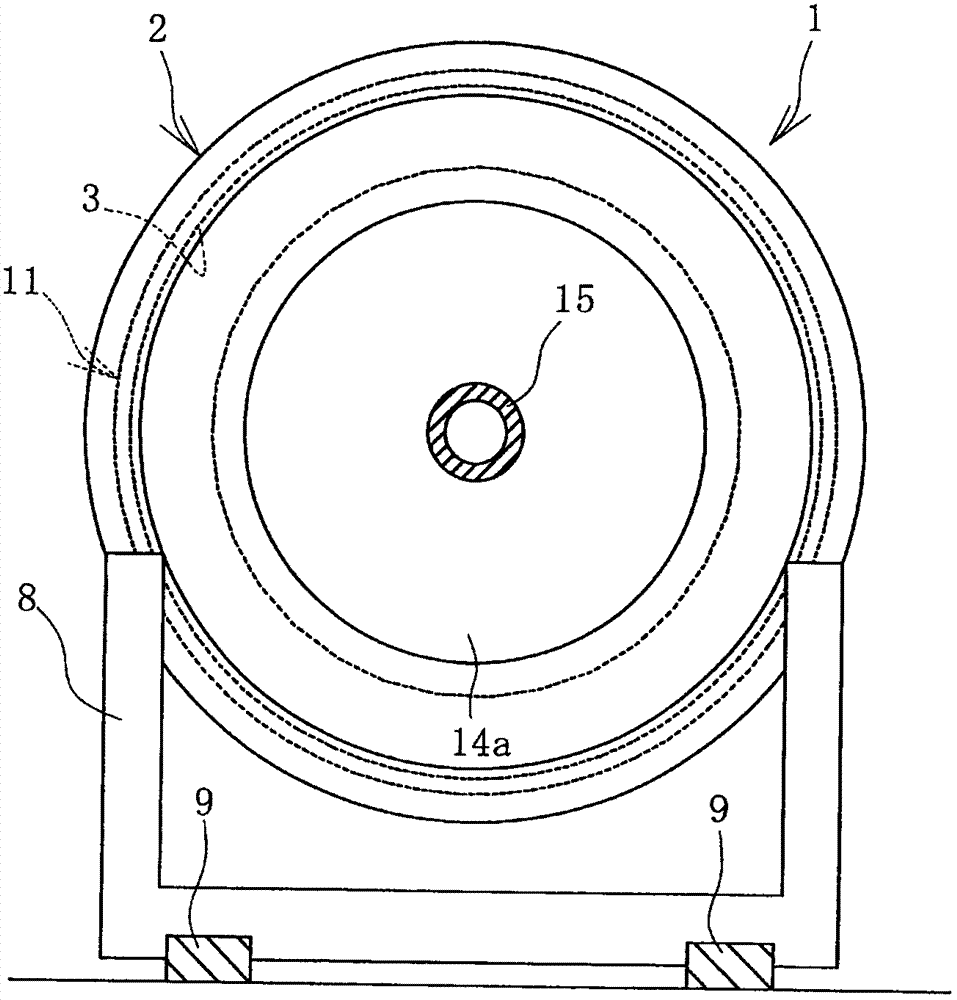

[0049] Such as figure 1 , figure 2 As an example, the pneumatic tire forming apparatus 1 of the present invention (hereinafter referred to as the forming apparatus 1) is an apparatus used when forming a green tire G on the outer periphery of the rigid inner mold 11. Tire components are sequentially laminated on the outer peripheral surface of the rigid inner mold 11 to complete the green tire G.

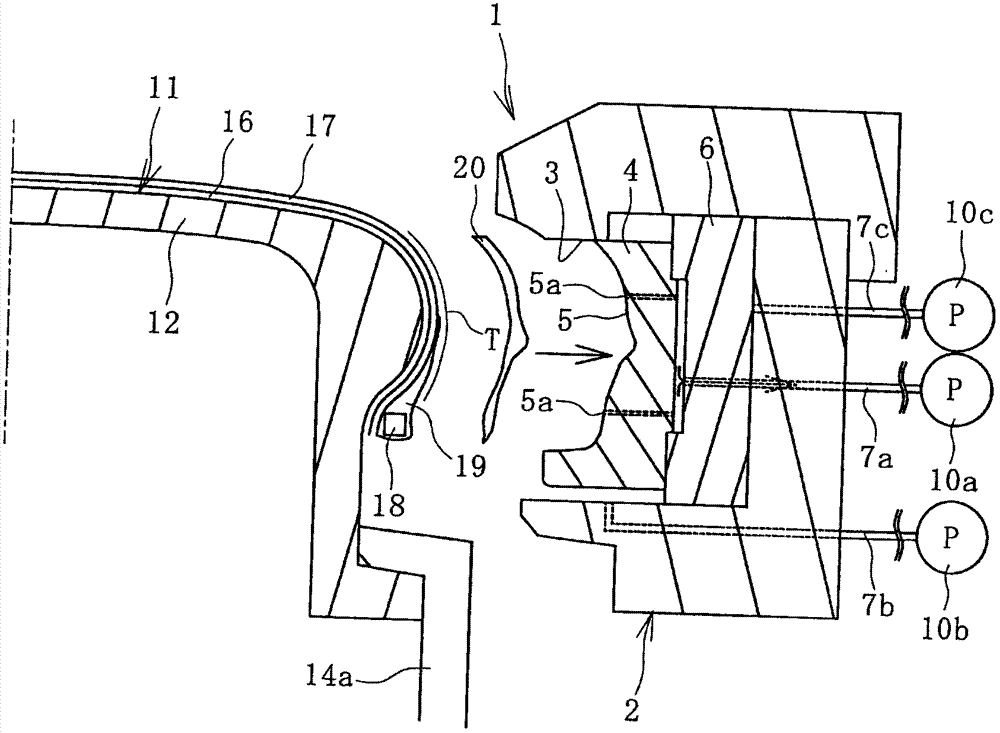

[0050] in image 3 On the outer peripheral surface of the rigid inner mold 11 illustrated in the example, the inner liner 16 and the carcass material 17 are laminated and arranged in this order. The carcass material 17 is erected between a pair of bead rings 18, and the bead rubber 19 is folded back around the bead ring 18 from the inside to the outside.

[0051] The rigid inner mold 11 has a cylindrical shape and is composed of a plur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com