Electronic vacuum pump control device, vacuum boosting system and vacuum boosting method

A technology of electronic vacuum pump and control device, which is applied in the direction of brake transmission, liquid tightness measurement using liquid/vacuum degree, brake, etc. It can solve the problem of limited braking force, inability to provide vacuum source, failure to meet brake pressure requirements, etc. problem, to achieve the effect of effective control and overtime fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

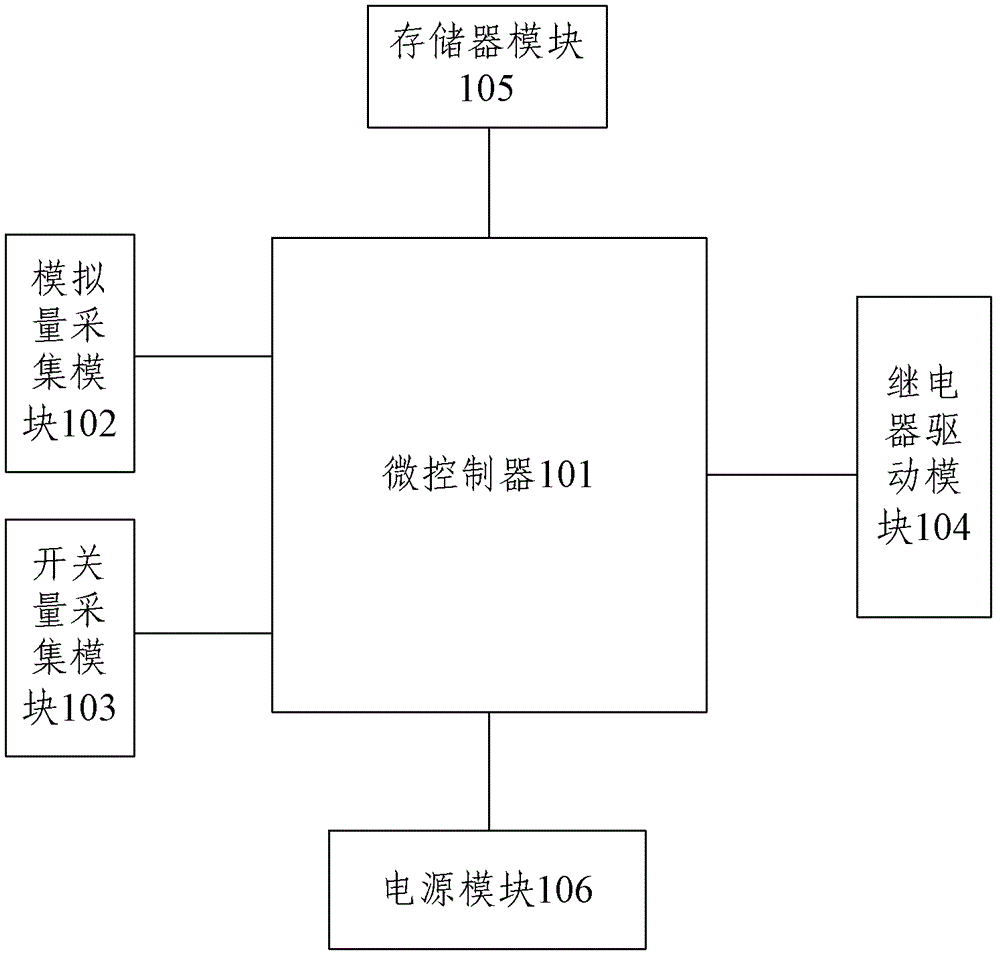

[0053] Such as figure 1 As shown, the electronic vacuum pump control device of the present invention includes: a microcontroller 101 , an analog quantity acquisition module 102 , a switch quantity acquisition module 103 , a relay drive module 104 , a memory module 105 and a power supply module 106 .

[0054] The analog quantity acquisition module 102 is connected with the microcontroller 101, filters and adjusts the analog quantity input by the pressure sensor, and sends the filtered and conditioned analog quantity to the microcontroller 101, wherein the analog quantity includes: voltage analog quantity, current Analog quantity or resistance analog quantity, the pressure sensor collects the pressure in the vacuum tank, that is, the vacuum degree, and converts the vacuum degree into voltage analog quantity, current analog quantity or resistance analog quantity, and filters and adjusts the above analog quantity, micro The A / D conversion module in the controller 101 quantizes the...

Embodiment 2

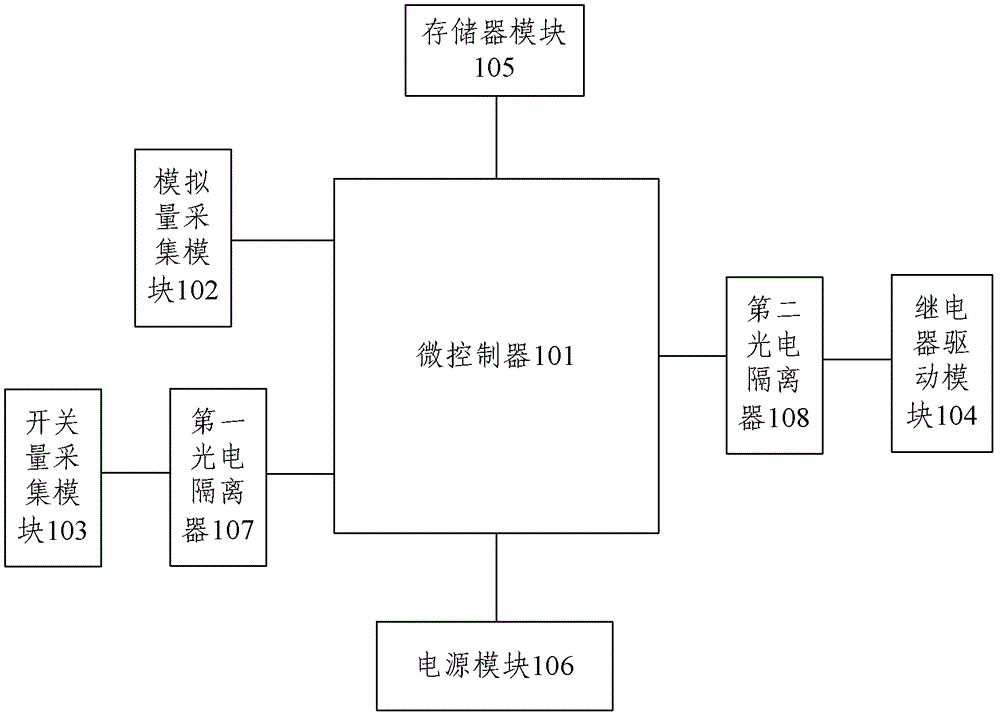

[0062] Such as figure 2 As shown, on the basis of Embodiment 1, a first photoelectric isolator 107 is added to the device, and the switching value acquisition module 103 is connected to the microcontroller 101 through the first photoelectric isolator 107 . A second photoelectric isolator 108 is also added, and the relay driving module 104 is connected to the microcontroller 101 through the second photoelectric isolator 108 .

[0063] The control flow of this embodiment is basically the same as that of Embodiment 1, the difference being that, in order to protect the microcontroller 101 (because the voltage and current that the microcontroller can withstand is relatively small), in case the sign collected by the switching value acquisition module 103 When the voltage or current value in the on / off state is too large, the microcontroller 101 is burned out, and the first photoelectric isolator 107 plays the role of reducing the voltage or current. Similarly, the second photoelect...

Embodiment 3

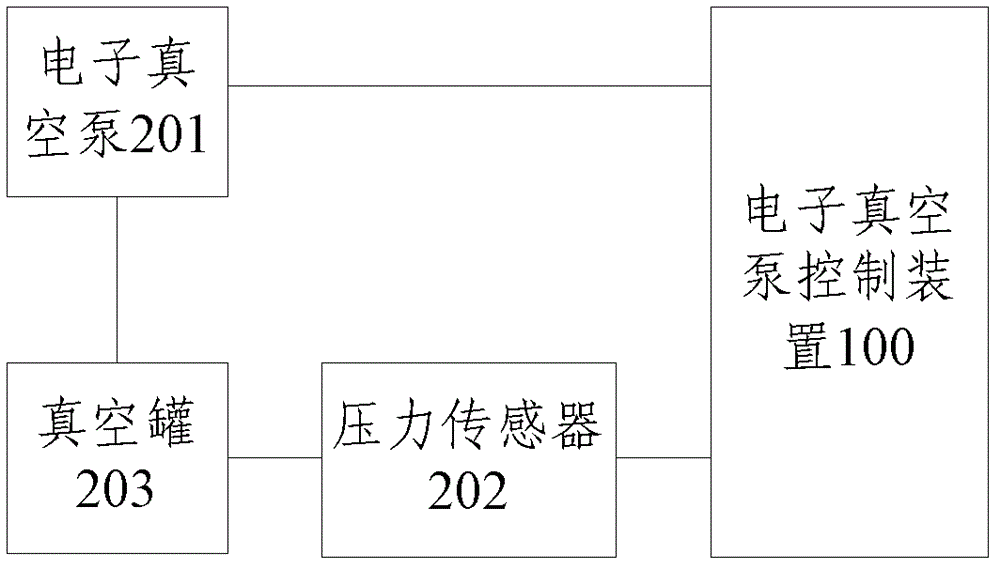

[0065] Such as image 3 As shown, the vacuum boosting system of the present invention includes: an electronic vacuum pump 201 , a pressure sensor 202 , a vacuum tank 203 and the electronic vacuum pump control device 100 of the above-mentioned embodiment 1 or 2. The electronic vacuum pump 201 and the vacuum tank 203 are connected through a vacuum tube; the pressure sensor 202 is connected to the vacuum tank 203 for real-time detection of the vacuum degree in the vacuum tank 203 . The electronic vacuum pump control device 100 is connected with an electronic vacuum pump 201 and a pressure sensor 202 , wherein the microcontroller 101 judges the airtightness of the vacuum tank 203 according to the change of the vacuum degree detected by the pressure sensor 202 .

[0066] The microcontroller 101 specifically includes: a vacuum degree acquisition module and an airtightness detection module, the vacuum degree acquisition module is connected to the analog quantity acquisition module 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap