Rotationally moulded storage tank

A storage tank and rotomolding technology, applied in the field of rotomolding storage tanks, can solve problems such as affecting the service life of rotomolding storage tanks, and achieve the effects of reducing potential safety hazards, reducing impact force, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

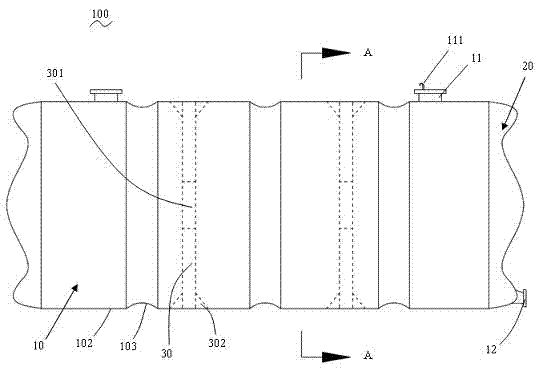

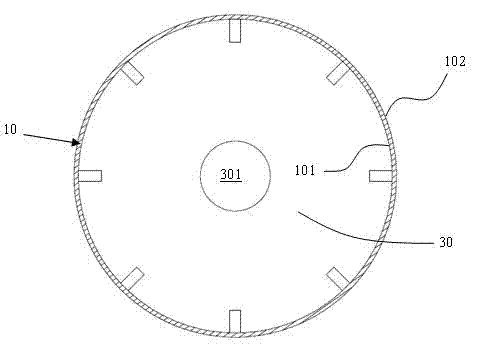

[0022] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of a specific embodiment of the rotomolded storage tank of the invention. In this embodiment, the rotomolded storage tank 100 includes: a cylindrical tank body 10 with a hollow structure inside; and caps 20 arranged at both ends of the tank body 10 . In this embodiment, the rotomolded storage tank 100 further includes at least two partitions 30 having through holes 301 and arranged parallel to each other. As shown in reference 2 , the partit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com