Dynamic positioning and dynamic tracking system of drag suction dredger and control method thereof

A trailing suction dredger, dynamic tracking technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problem of reducing the efficiency and accuracy of dredging operations, the inability to realize the control of the position and trajectory of the trailing suction dredger, and no positioning Problems with the dynamic tracking system to achieve the effect of improving dredging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

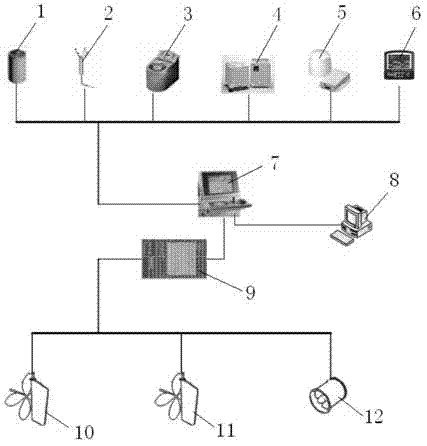

[0028] Dynamic positioning and dynamic tracking system of trailing suction dredger, including console, programmable logic controller, heading measuring device, position measuring device, wind direction and wind speed measuring device, ship motion attitude measuring device, propeller and steering gear; console connection Control the programmable logic controller, course measuring device, position measuring device, wind direction and wind speed measuring device, ship motion attitude measuring device, propeller and steering gear, carry out dynamic positioning and dynamic tracking of the ship, and accurately control the dredging operation of the trailing suction dredger.

[0029] The specific structure of this embodiment is described in detail as follows:

[0030] The dynamic positioning and dynamic tracking system of trailing suction dredger consists of console, programmable logic controller (PLC), ship attitude movement measurement unit, wind direction and wind speed measurement ...

Embodiment 2

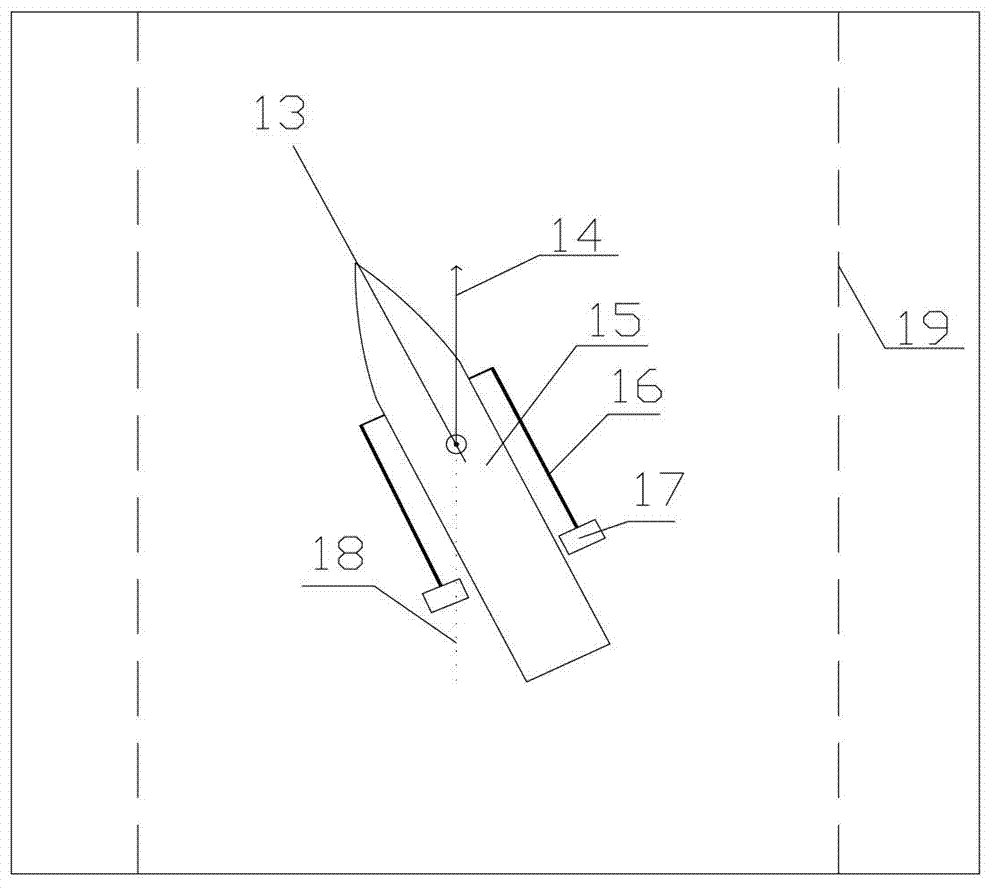

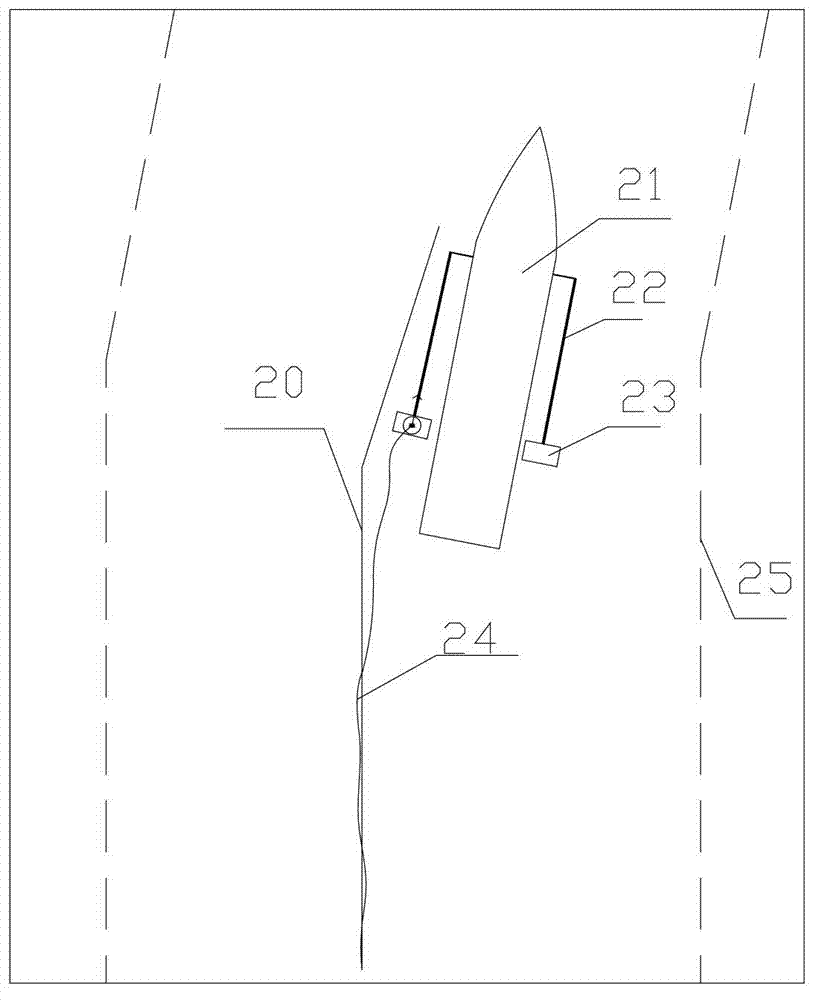

[0039] For the dynamic positioning and dynamic tracking control method of the trailing suction dredger, refer to the components of Embodiment 1, the console is connected to control the programmable logic controller, the heading measuring device, the position measuring device, the wind direction and wind speed measuring device, the ship motion attitude measuring device, Propeller and steering gear; the console collects the information of heading measuring device, position measuring device, wind direction and wind speed measuring device, and ship motion attitude measuring device, and detects the actual position and target position, actual moving direction and target of trailing suction dredger and rake head According to the influence of wind, wave and current external disturbance force, calculate the thrust required to return to the target position, and the programmable logic controller controls the thruster on the dredger to generate corresponding pitch and rudder angle command s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com