Hydraulic support roping rigging and roping system

A technology of hydraulic support and rigging, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of large safety threats and easy forward tilt of hydraulic supports, so as to improve work safety and reliability and avoid unsafe transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

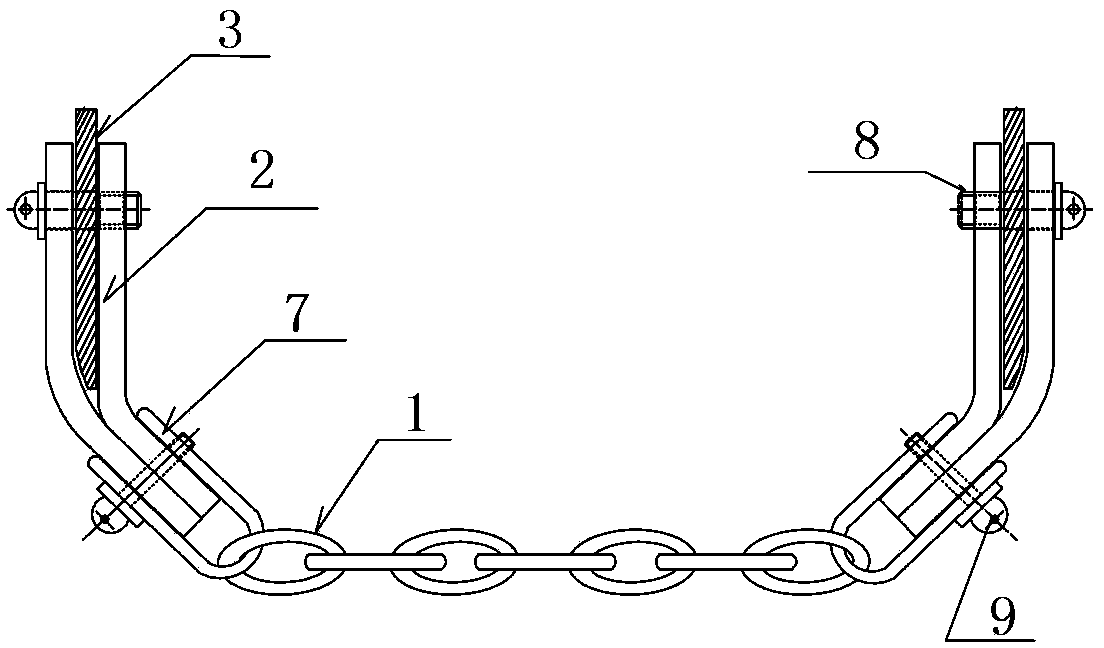

[0016] figure 1 It is a schematic diagram of the structure of the hydraulic support rigging provided in Embodiment 1 of the present invention. The embodiment of the present invention provides a hydraulic support hauling rigging, which is suitable for hauling the hydraulic support in the inclined roadway working face in coal mining, wherein , the hauling sling includes a chain 1 and two connecting assemblies 2, the two connecting assemblies 2 are respectively used to fix the guard plate 3 on the rear side of the hydraulic support; the two ends of the chain 1 are respectively connected to the connecting assemblies 2 for Hooked with the wire rope of the winch to pull the hydraulic support, wherein the hook head connected to the wire rope bypasses the chain 1 and is fixedly connected downward to the flatbed truck, and the hooking position of the wire rope and the chain 1 is higher than the fixed position of the hook head and the flatbed truck.

[0017] figure 2 The front view of...

Embodiment 2

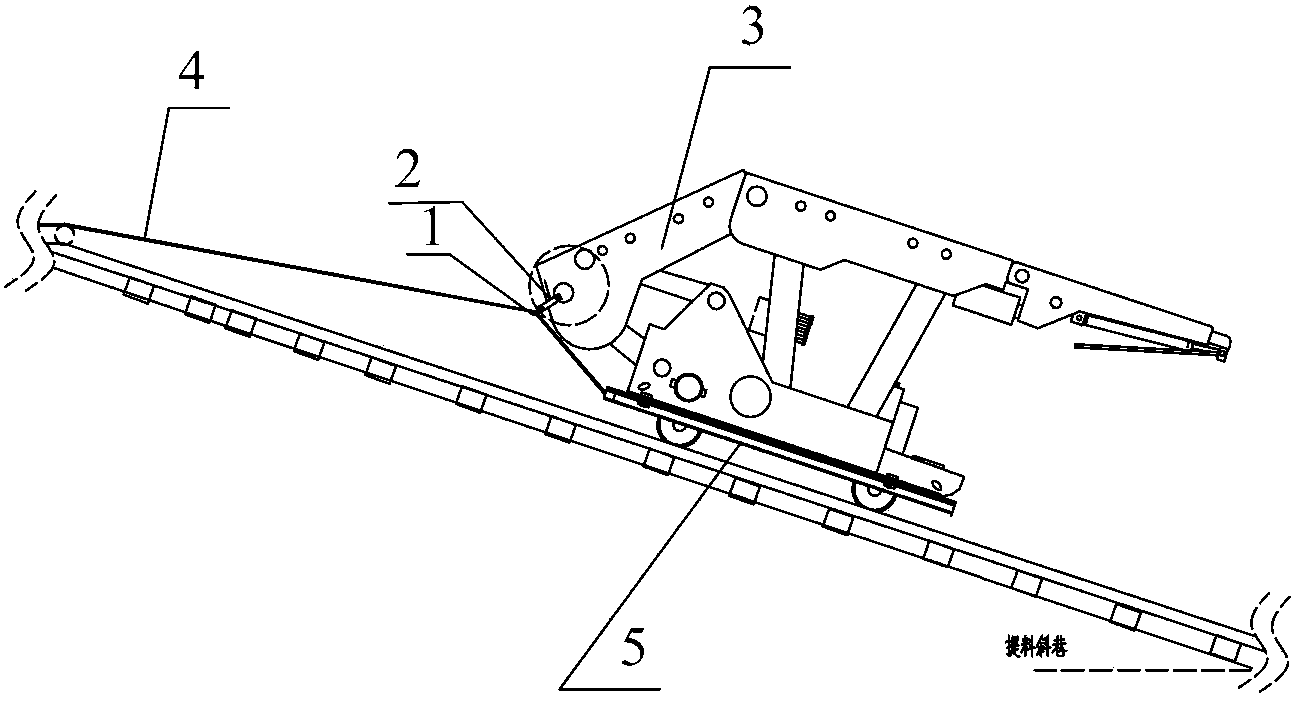

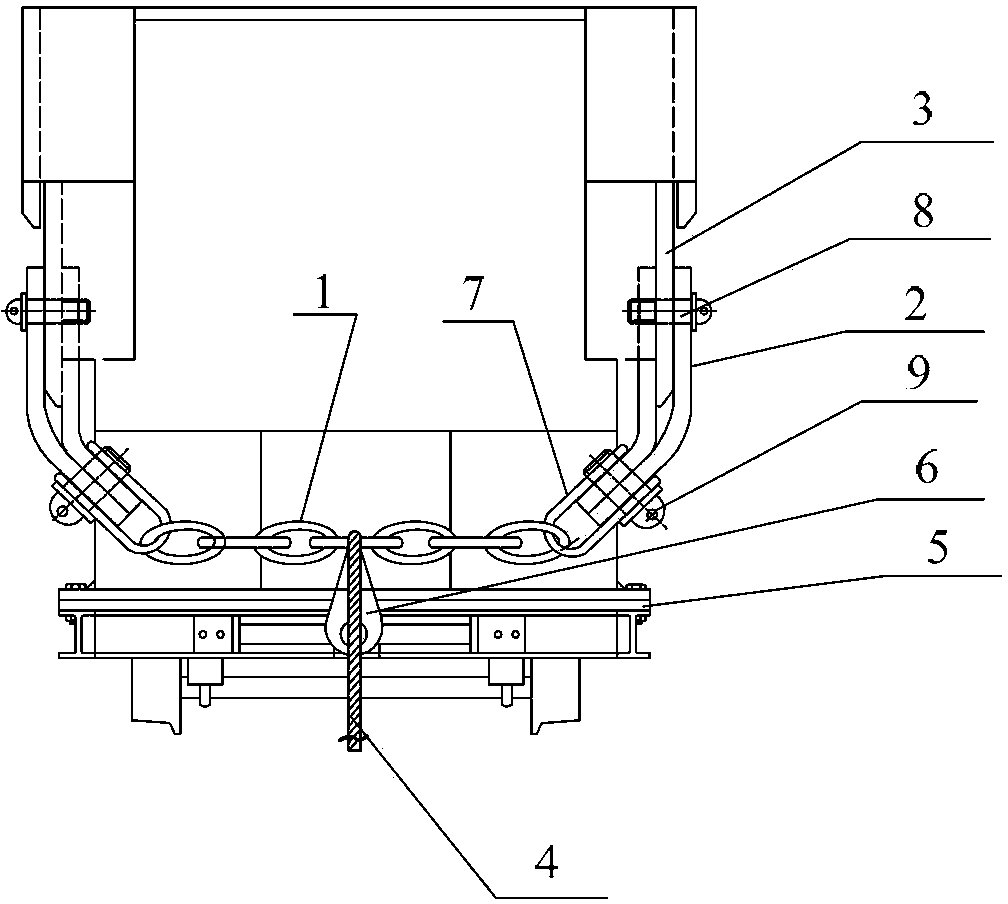

[0023] figure 2 It is a front view of the structure of the hydraulic support hauling system provided in Embodiment 2 of the present invention, image 3 It is a front view of the partial structure of the hydraulic support hauling system provided by Embodiment 2 of the present invention. Embodiment 2 of the present invention provides a hydraulic support hauling system, including a flatbed truck 5 and a winch (not shown), the flatbed truck 5 is used to be fixed with the hydraulic bracket, and carries the hydraulic bracket; the winch includes hooks 6 connected together and steel wire rope 4, wherein, the system also includes the hauling sling provided by any embodiment of the present invention, the connecting assembly 2 of the sling is fixed to the guard plate 3 on the rear side of the hydraulic support; Through the chain 1, the hook head 6 is fixedly connected with the flatbed truck 5, and the steel wire rope 4 is hooked with the chain 1.

[0024] The hydraulic support hauling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com