Automatic automotive diesel engine fuel pipe intake air exhaust mechanism

An automatic emptying, diesel engine technology, applied in the direction of machines/engines, electrical components, electromechanical devices, etc., can solve the problems of waste, pollution, increase labor intensity and difficulty, and achieve the effect of eliminating labor intensity and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

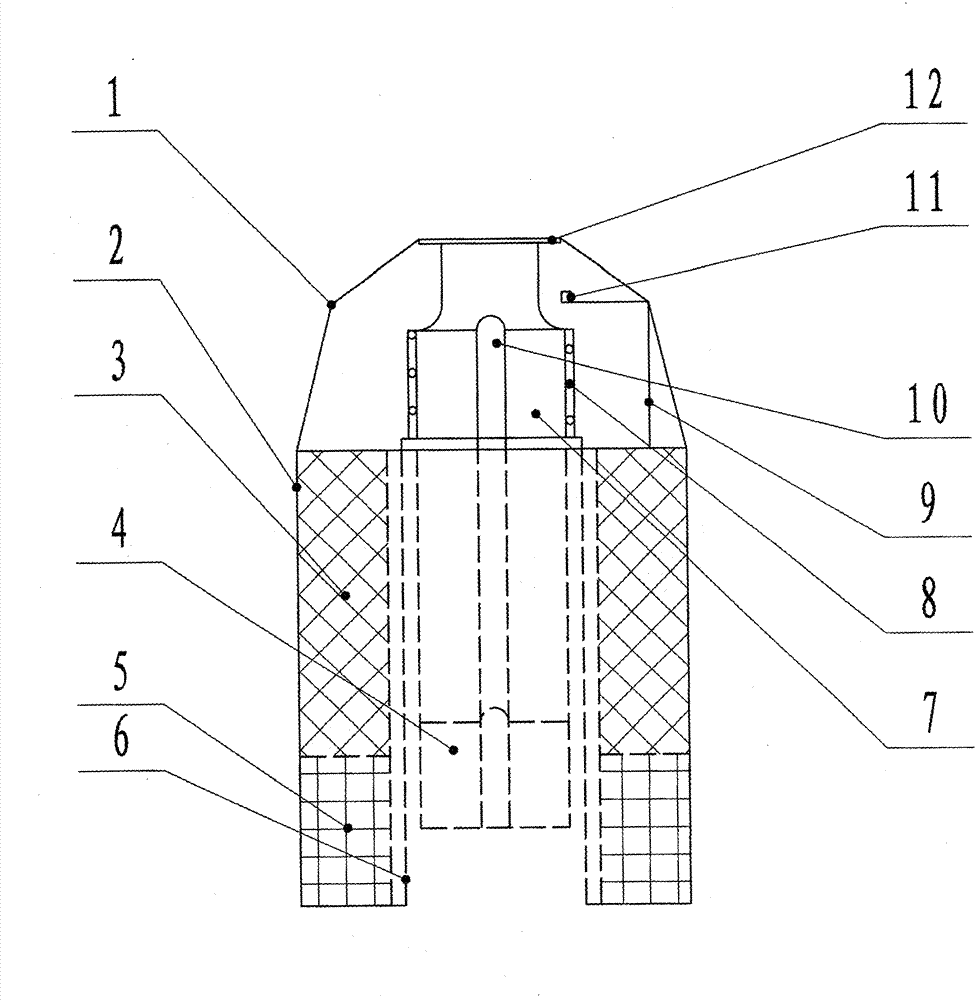

[0018] Refer to attached figure 1 , the thrust generating device is composed of: sealing cap (1), housing (2), starting coil (3), push body (4), stroke coil (5), inner sleeve (6), spool (7), traction Spring (8), bracket (9), air groove (10), travel switch (11), pressing table (12) are used to generate the thrust of the vehicle manual fuel pump; adjust the position of the thrust generating device and the manual fuel pump, Make the pushing body (4) contact with the manual fuel pump accordingly, when the starting coil (3) is energized, the spool (7) will start to move downward under the action of the electromagnetic force generated by the starting coil (3). After the spool (7) moves for a certain stroke, press the table (12) to make the stroke switch (11) fixed on the bracket (9) act, thereby turning on the power supply of the stroke coil (5) and cutting off the power supply of the starting coil (3). Power supply, because the start coil (3) and stroke coil (5) adopt a certain po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com