Axial-loading biconical traction drive device

A technology of traction transmission and axial loading, which is applied in the direction of transmission devices, friction transmission devices, belts/chains/gears, etc., can solve the problem of fewer continuously variable transmissions, and achieve large power transmission, high transmission efficiency, and wide transmission range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

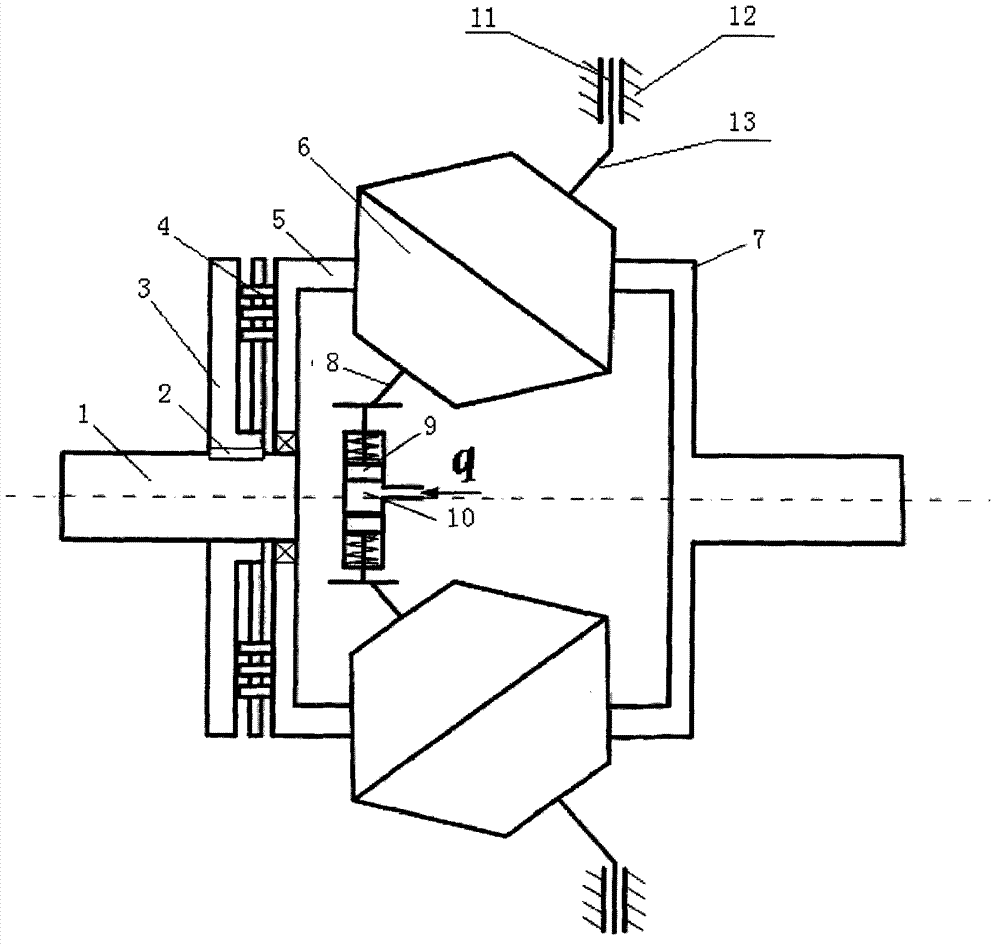

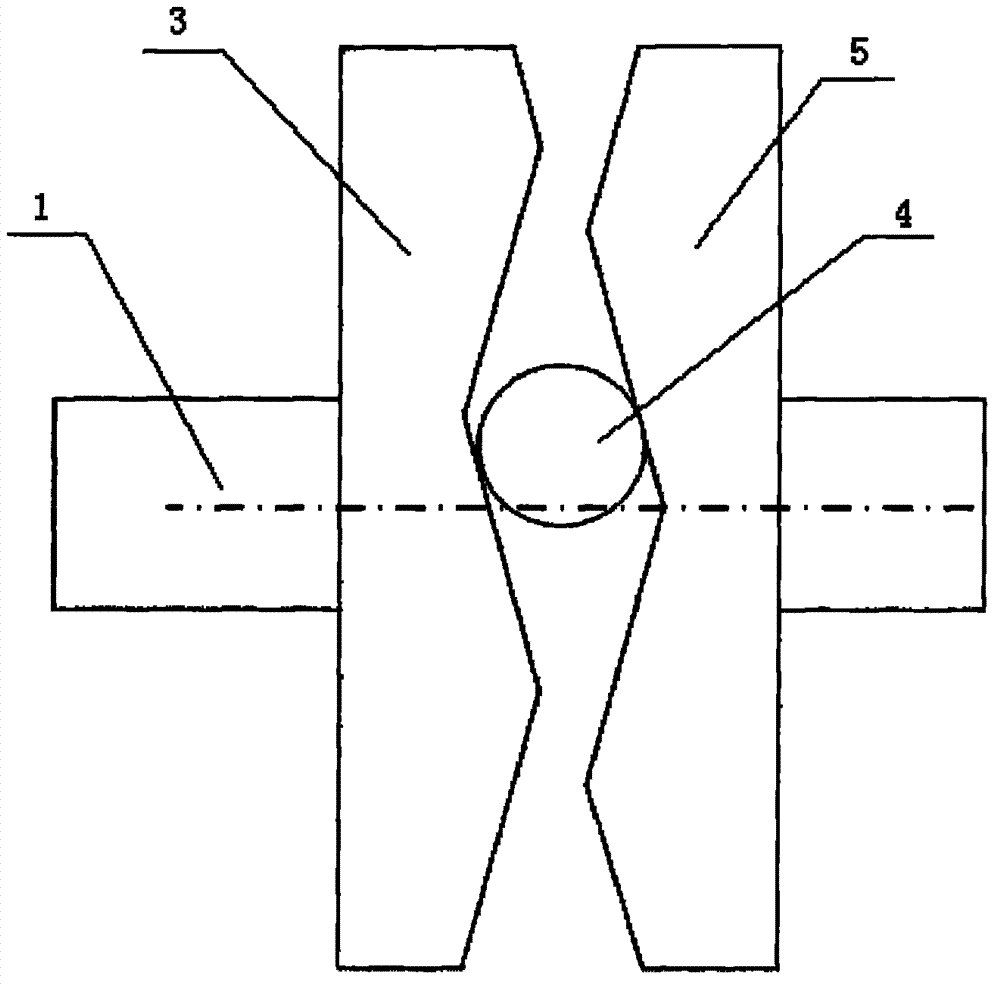

[0016] Such as figure 1 , figure 2 As shown, the technical solution of the present invention is: an axially loaded double-cone traction transmission device, which is characterized in that it includes an input shaft 1, a spline 2, a cam loading mechanism, more than one set of speed regulating mechanisms, a hydraulic pressure Tightening mechanism, inner support shaft 8 and output wheel 7; its peripheral equipment is a box;

[0017] Wherein, the cam loading mechanism is composed of loading wheel 3, rolling body 4 and input wheel 5;

[0018] The speed regulating mechanism is composed of a double cone 6, an outer support shaft 13, a moving rod 11 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com