Oil retainer structure of novel three-phase asynchronous motor

A three-phase asynchronous, oil retaining ring technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of difficult assembly, difficult processing, long cycle, etc., and achieve the effect of convenient operation, simple processing and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

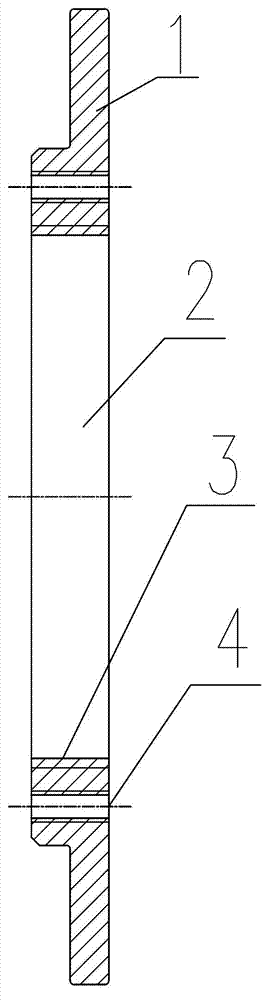

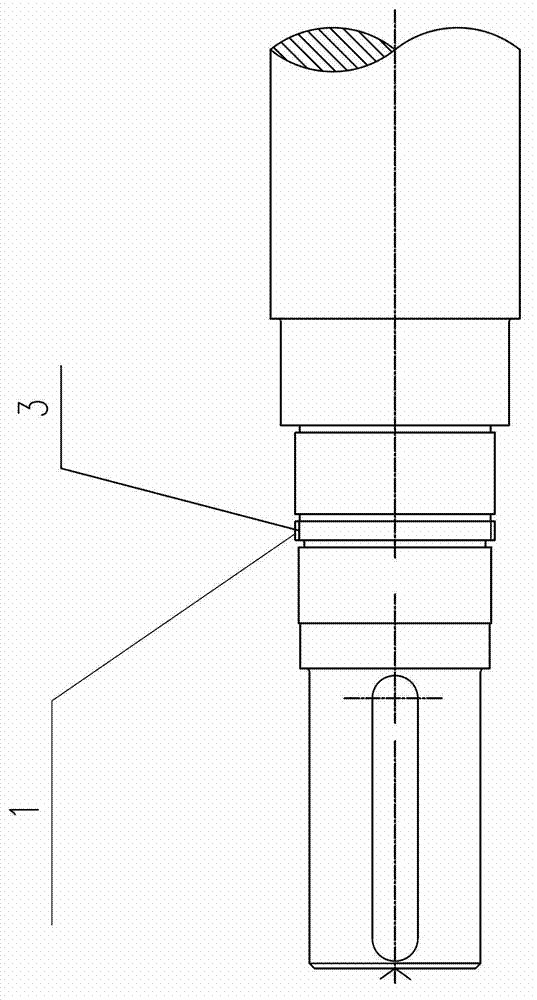

[0010] Such as Figure 1 ~ Figure 2 As shown, it includes an oil deflecting ring body 1, on which the oil deflecting ring body 1 is provided with a central hole 2 of the oil deflecting ring, and a thread 3 is arranged in the central hole 2 of the oil deflecting ring, and on the said oil deflecting ring body 1 is equidistantly provided with small holes 4,

[0011] The present invention only needs to change the fit of the oil deflecting ring, from interference fit to thread fit; the corresponding part shaft is provided with thread. The M140X2 thread is a thread with a diameter of 140 and a pitch of 2.

[0012] The cooperation between the oil retaining ring body 1 and the shaft is replaced by threaded connection M140X2, and the rest remains unchanged. The threaded connection does not need to be heated, as long as it is tightened along the thread, no additional e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com