Patents

Literature

41results about How to "Reasonable processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

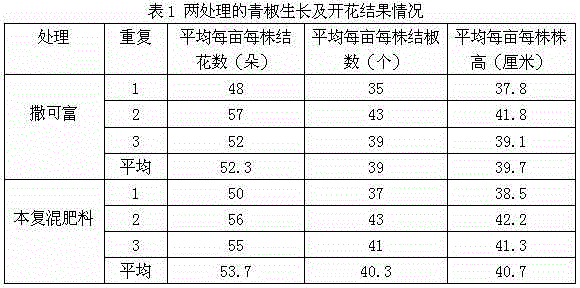

Humic acid type functional compound fertilizer and preparation method thereof

InactiveCN104447009APromote absorptionImprove disease resistanceSuperphosphatesMagnesium fertilisersVitamin B12Pantothenic acid

The invention discloses a humic acid type functional compound fertilizer and a preparation method thereof and relates to the technical field of compound fertilizers. The humic acid type functional compound fertilizer comprises a basic fertilizer nitrogen, phosphorus and potassium and auxiliary raw materials including humic acid, attapulgite powder, a granulating solution and granulating powder, wherein the granulating solution comprises the following ingredients in percentage by mass: 0.1-3 percent of an animal amino acid, 1-20 percent of urea, 0.3-3 percent of zinc sulfate, 0.1-2.5 percent of manganese sulfate, 0.1-0.8 percent of boric acid, 0.1-0.3 percent of sodium molybdate, 0.1-1 percent of magnesium sulfate, 0.1-0.3 percent of compound sodium nitrophenolate and the balance of water; the granulating powder comprises the following ingredients in parts by mass: 0.3-25 parts of ferrous sulfate, 0.1-0.5 part of copper sulfate, 0.1-0.3 part of vitamin B12, 0.1-0.3 part of para aminobenzoic acid, 0.1-0.3 part of cobalt chloride, 0.1-1 part of calcium pantothenate, 0.1-1 part of EDTA-2Na and 0.1-0.3 part of sodium selenite. The fertilizer disclosed by the invention is high in utilization rate and can be used for increasing the yield of crops.

Owner:王意强 +1

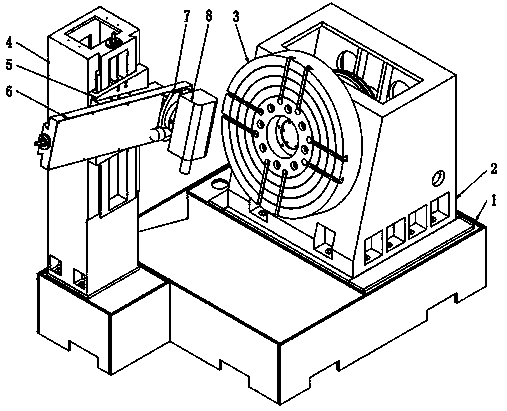

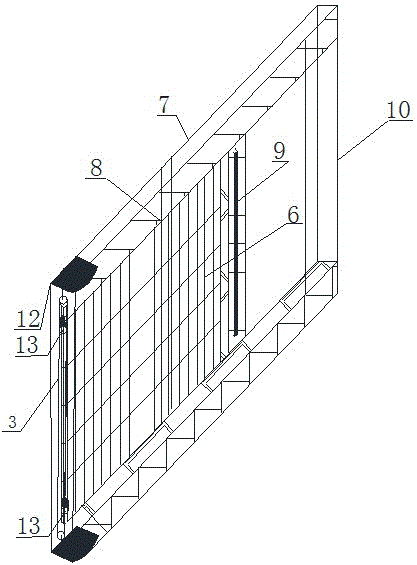

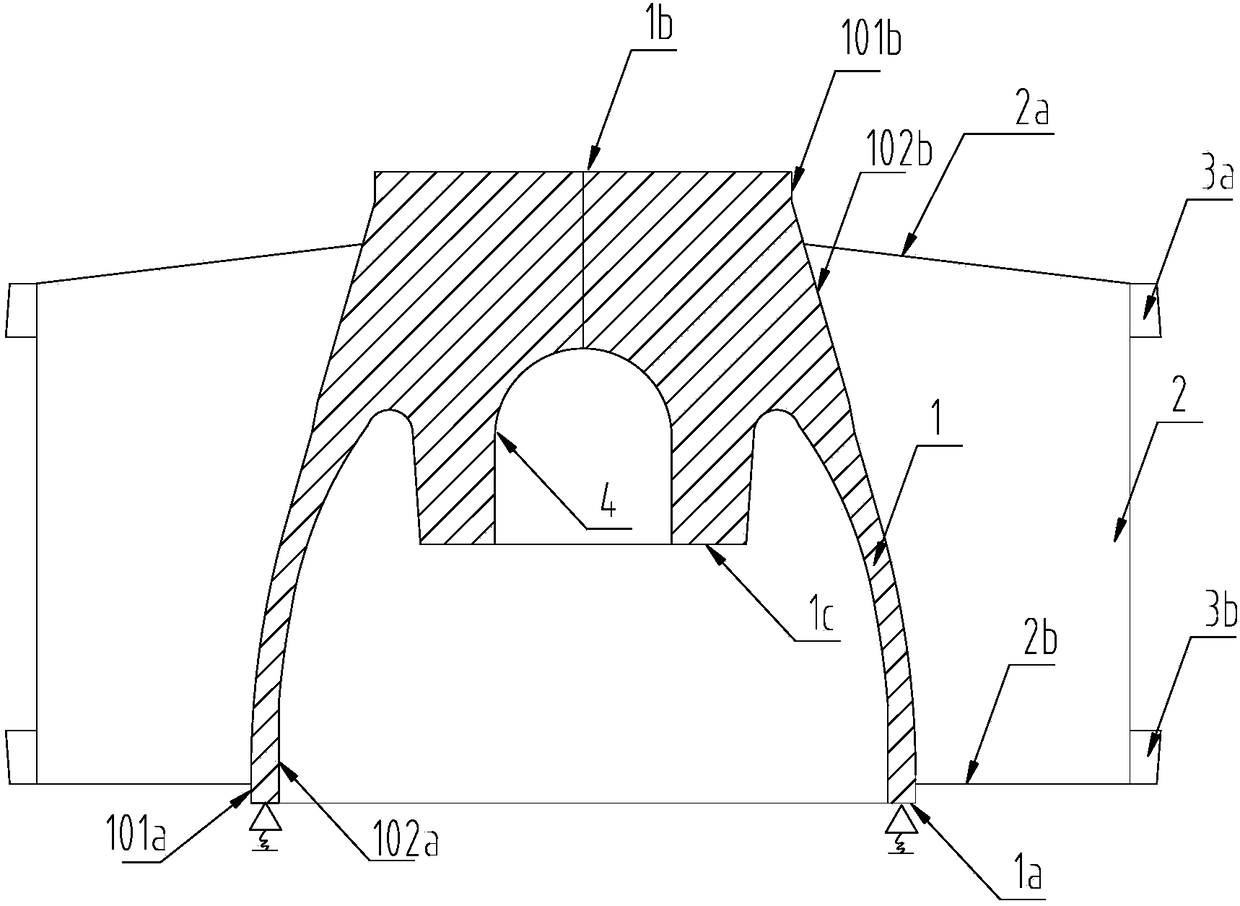

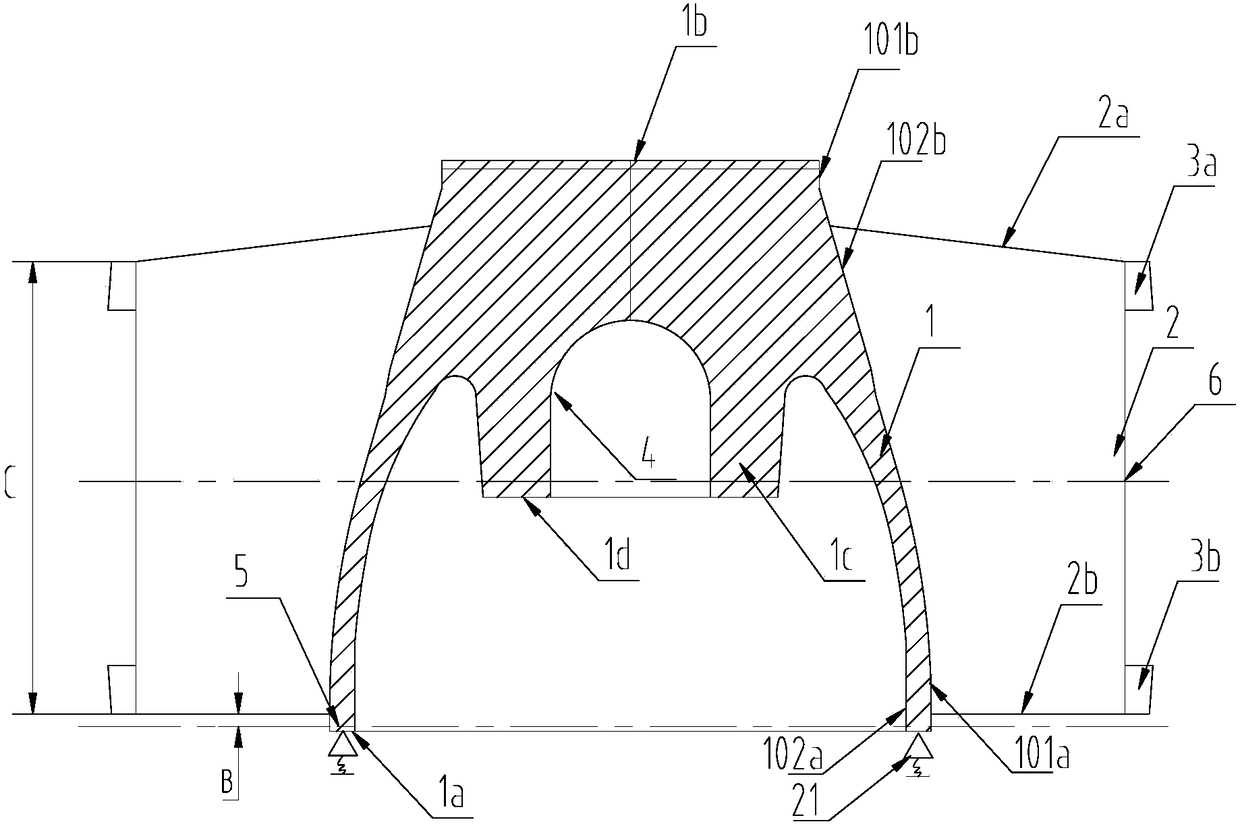

Novel electric discharge machining machine tool for heavy-duty tire mold

InactiveCN103934522AEasy clampingHigh rotation accuracyElectrical-based auxillary apparatusElectric dischargeEngineering

The invention discloses a novel electric discharge machining machine tool for a heavy-duty tire mold. The novel electric discharge machining machine tool comprises a base. A rotation box is arranged on the base. A main shaft in the rotation box is connected with a four-jaw chuck. The face, making contact with the four-jaw chuck, of the rotation box tilts by 15 degrees. A stand column is arranged on the base. An inclined sliding plate capable of moving up and down along a guiding rail face is arranged on the stand column. An included angle formed between the inclined sliding plate and the stand column is 15 degrees. A beam is arranged on the inclined sliding plate, wherein an included angle formed between the stand column and the beam is 15 degrees. The beam can move in the direction perpendicular to the four-jaw chuck. A division rotary table is arranged at the front end of the beam. A discharging machine head is arranged on the division rotary table. The novel electric discharge machining machine tool for the heavy-duty tire mold is simple in clamping, high in rotation precision, free of timing adjustment, reasonable in machining, high in product quality and high in speed, efficiency and precision, and has the adjustable machine head.

Owner:QINGDAO YONGHEYUAN PRECISION WORK

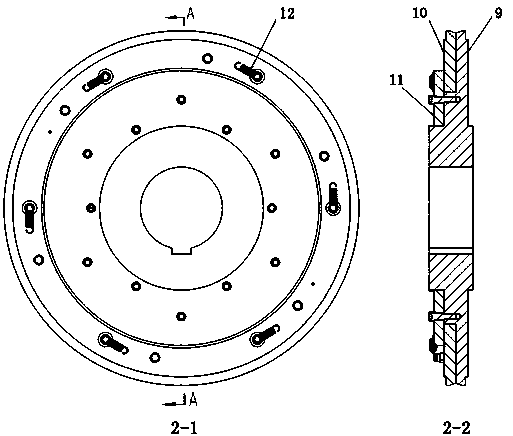

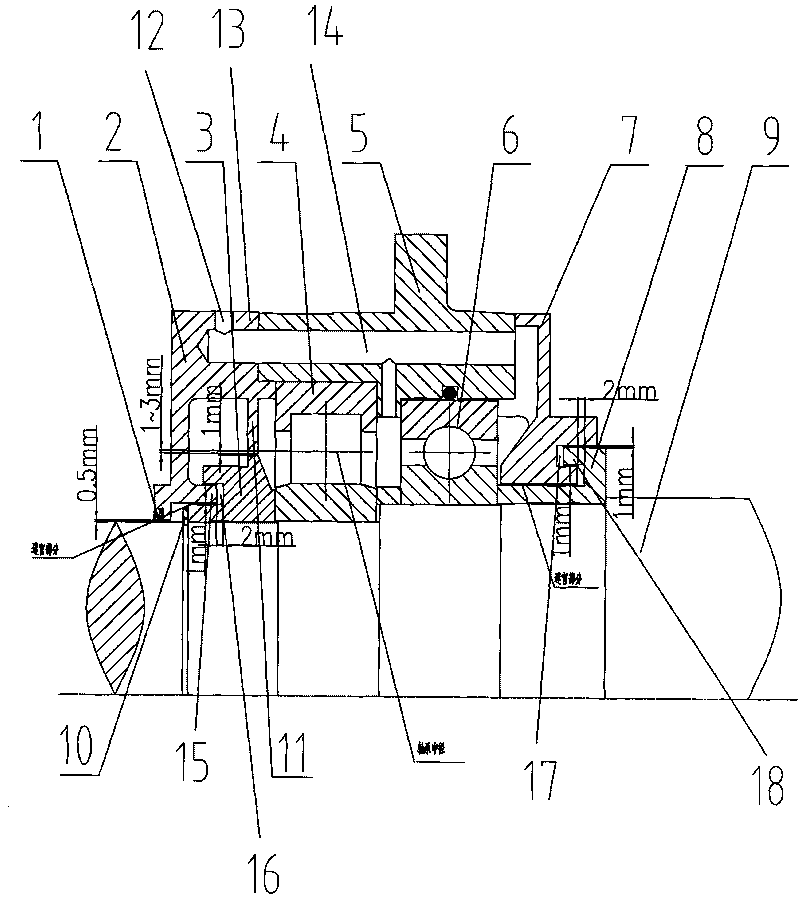

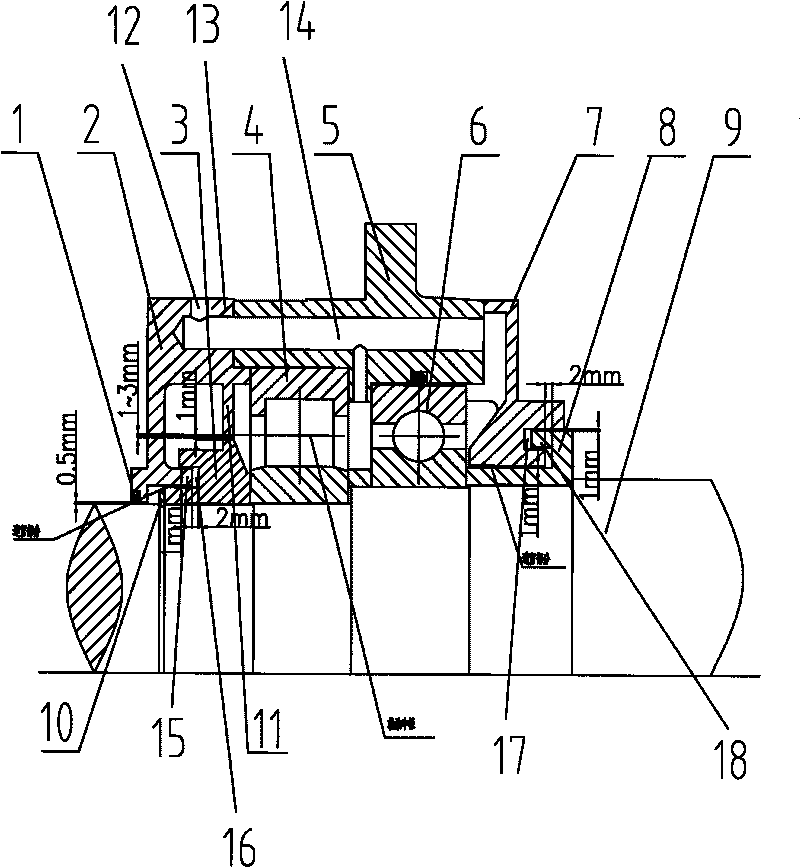

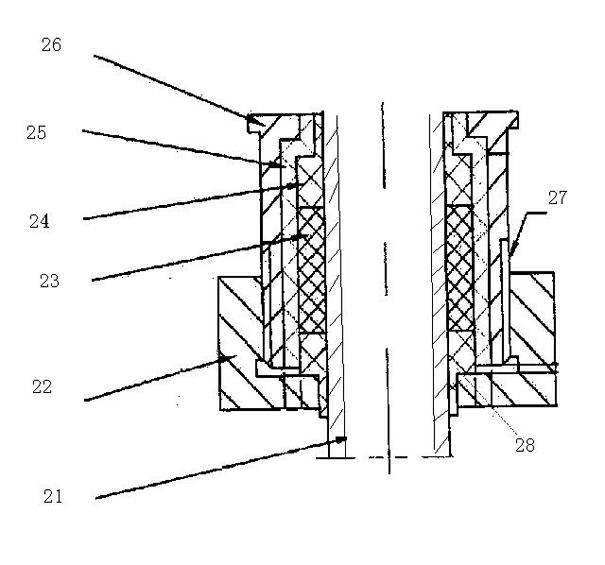

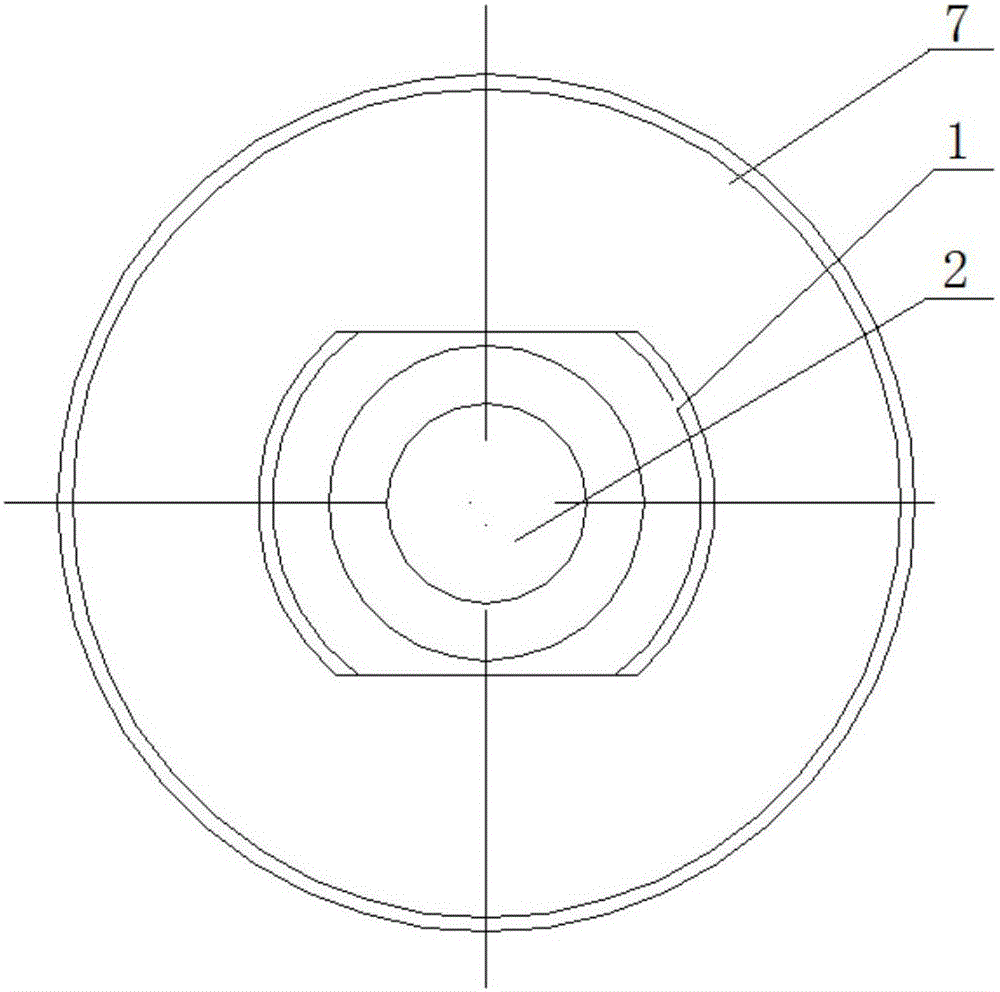

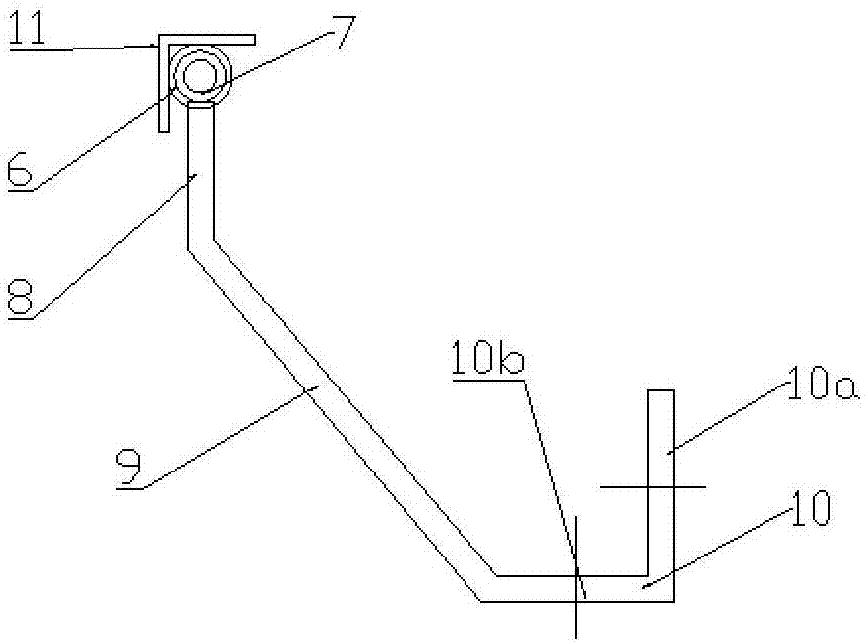

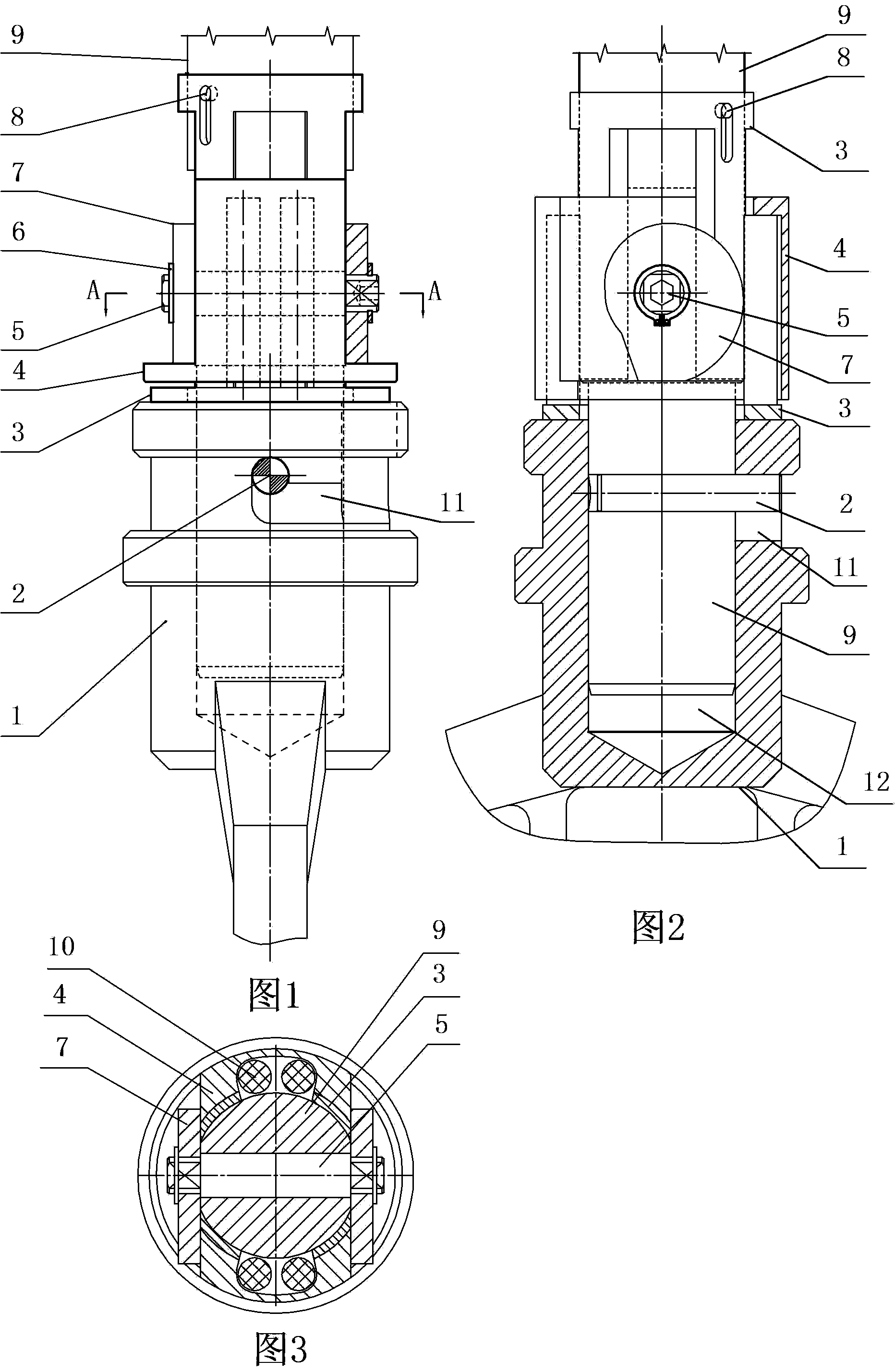

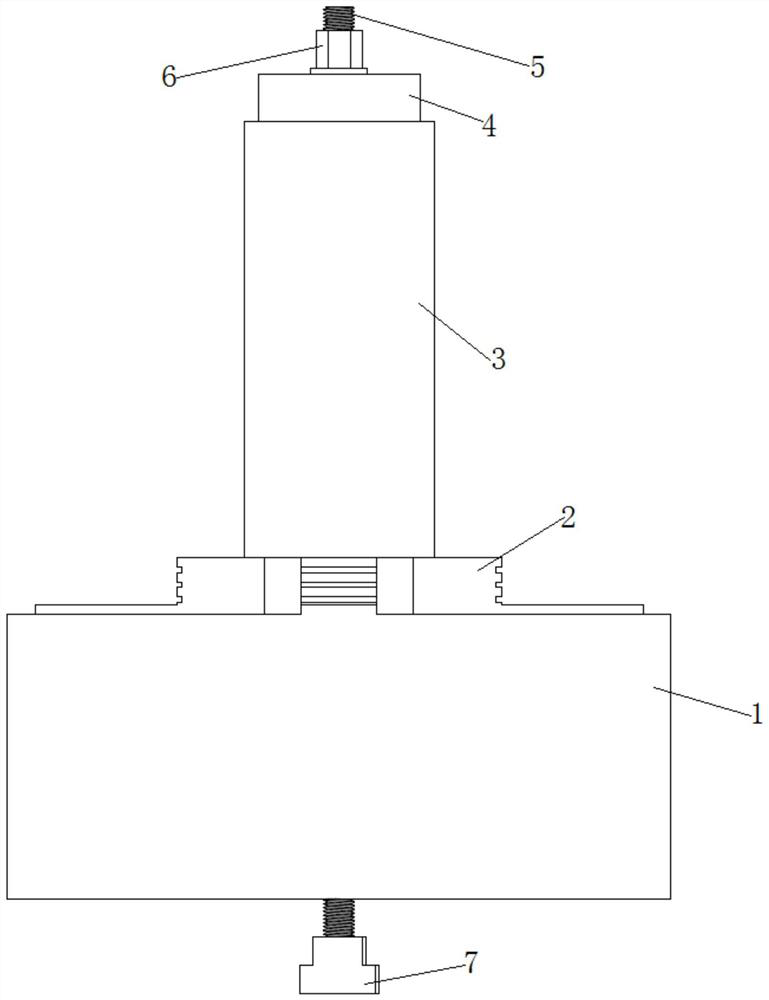

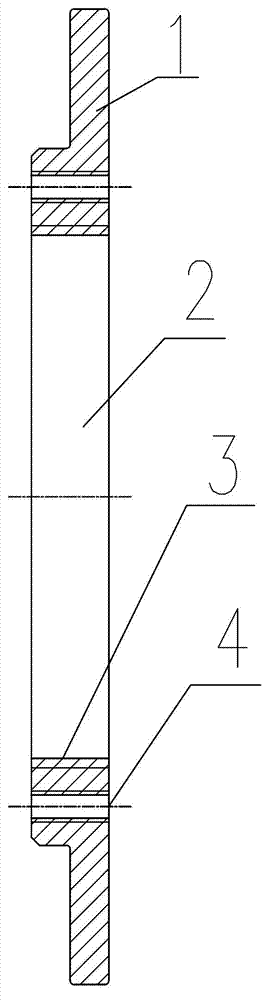

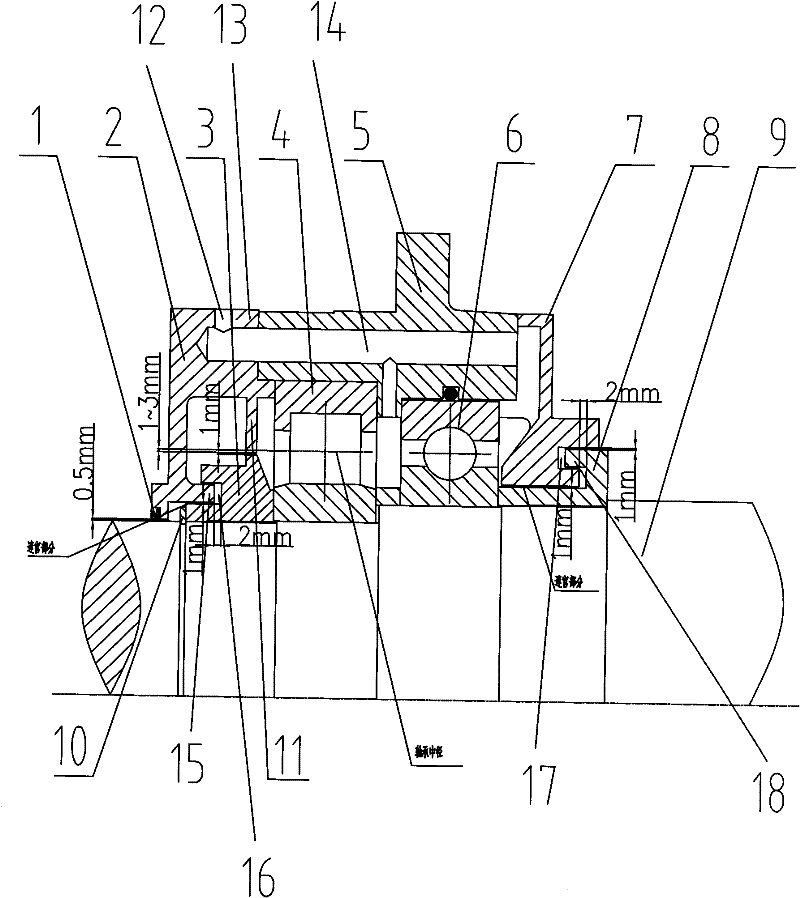

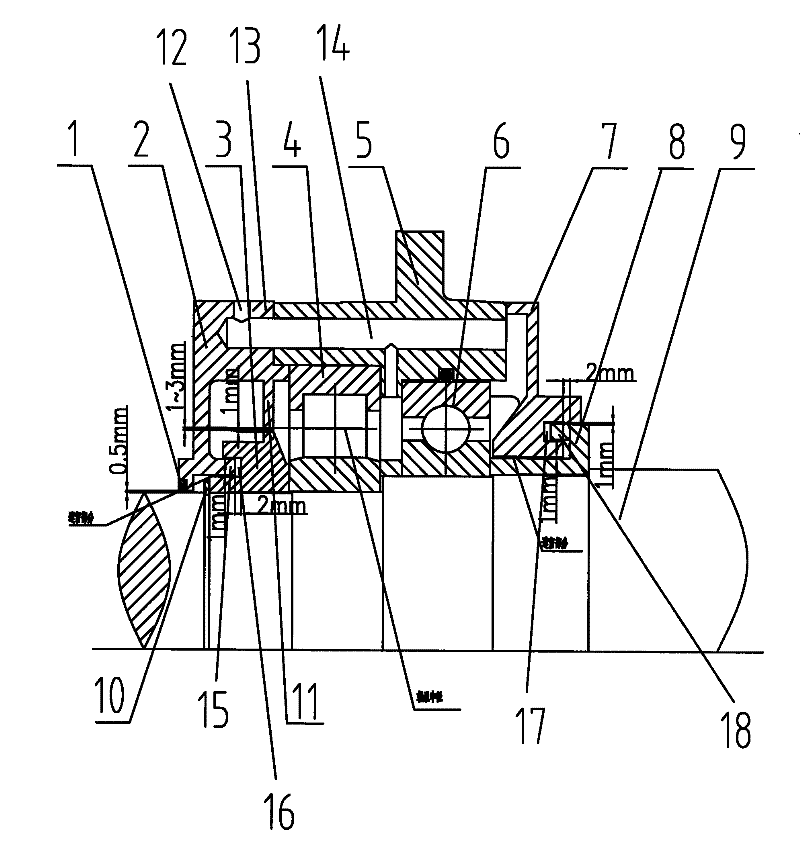

Oil storage device of high-pressure motor bearing

InactiveCN101710749AEasy to processReasonable processingSupports/enclosures/casingsEngine lubricationHigh pressureCentrifugal force

The invention relates to an oil storage device of a high-pressure motor bearing, which is mainly used for improving the protection grade of the high-pressure motor bearing, such as the functions of dust prevention and water prevention. An oil throwing disk is fixed on a rotating shaft of a motor, a V-shaped ring is put in the outer end of an inner ring of a left cover of the bearing to improve the protection grade, and the inner side of a bearing set is fixed through a right cover of the bearing. The oil storage device is characterized in that labyrinth parts are arranged on an inner cover and an outer cover of the bearing, and the left cover of the bearing is internally and additionally provided with the inner ring. The oil storage device has simple, compact and reasonable structure and obvious effect. Under the condition of not changing structure materials, the protection grade of the motor is effectively improved through additionally arranging a labyrinth ring and the labyrinth parts on the inner cover and the outer cover of the bearing and the oil throwing disk. The inner ring is additionally arranged in the left cover of the bearing, and lubricating oil is thrown into an oil storage cavity in the inner ring and the bearing due to the action of centrifugal force, thus the oil storage capacity is greatly enhanced. For part processing, the oil storage device is simple and reasonable and has no influence on mechanical property of workpieces, and for mechanical deviation, because a single radial edge is preserved with an allowance of 1mm and a single axial edge is preserved with an allowance of 2mm, the assembly of the parts have no problems.

Owner:SEC ELECTRIC MACHINERY

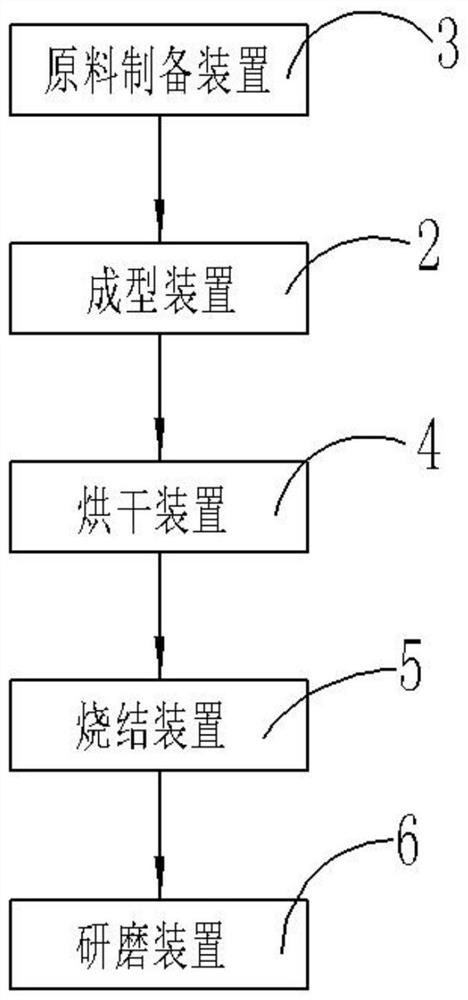

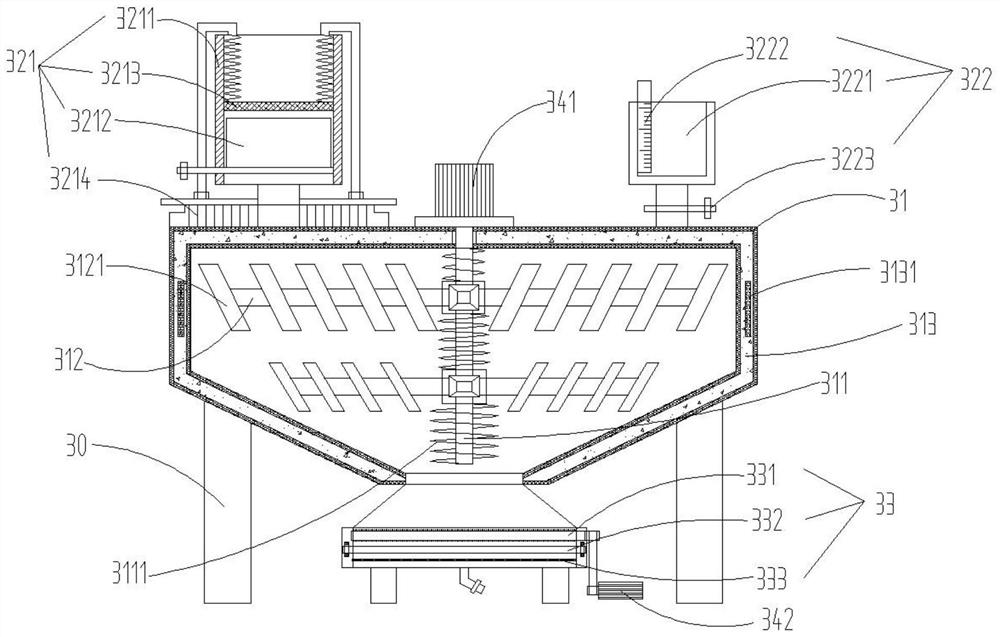

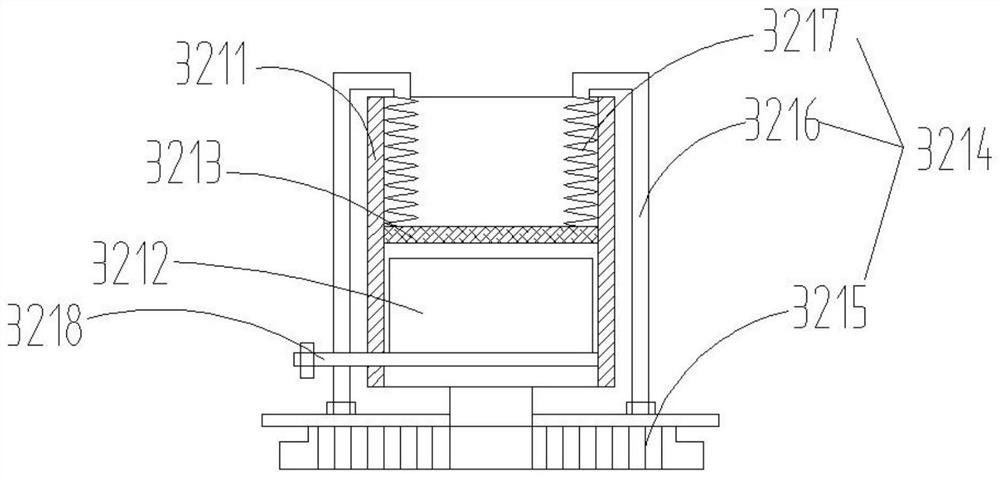

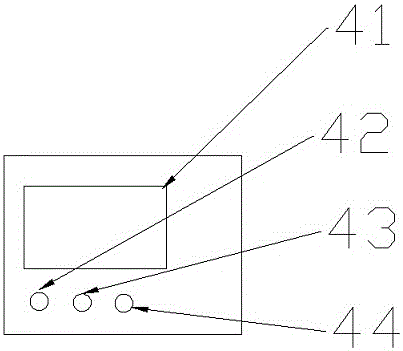

Electronic ceramic production system

ActiveCN111645182AReduce the possibilityGuarantee product qualityGrinding carriagesGrinding drivesMoulding deviceWhole systems

The invention relates to an electronic ceramic production system. According to the electronic ceramic production system, electronic ceramic processing is achieved by combining multiple devices, the whole system is reasonable in processing, firstly, the raw material preparation device is used for preparing high-quality ceramic slurry, then the high-quality ceramic slurry is put into the forming device for automatic forming, a green body is put into the drying device for drying after forming, the green body is preliminarily dried, in order to prevented cracks from being generated in the sintering process, the green body is placed in the sintering device after drying, by designing a feeding and taking structure of the sintering device, a user cannot be scalded in the using process, ceramic production is completed after sintering is completed, surface treatment of a ceramic product is carried out in the next step, the grinding device adopted for surface treatment is good in grinding effect, and meanwhile, dust generated in the grinding process is collected, so that dust pollution in a processing workshop is avoided; and electronic ceramics produced by using the whole system are high inquality, the whole system is used in the workshop, so that cleanliness of the workshop is guaranteed, and the safety production effect is improved.

Owner:新化县正能精细陶瓷有限公司

Humic acid type functional blended fertilizer and preparation method thereof

ActiveCN104447010APromote absorptionImprove disease resistanceMagnesium fertilisersAlkali orthophosphate fertiliserVitamin B12Manganese

The invention discloses a humic acid type functional blended fertilizer and a preparation method thereof, and relates to the technical field of blended fertilizers. The humic acid type functional blended fertilizer comprises nitrogen phosphorus and potassium, humic acid, attapulgite powder, a coating film, a granulation material, nitrogen fertilizer film coating liquid, nitrogen fertilizer film coating powder, phosphorus fertilizer film coating liquid, potassium fertilizer granulation liquid and potassium fertilizer granulation powder, wherein the nitrogen fertilizer film coating liquid comprises animal amino acids, urea, zinc sulfate, manganese sulfate, boric acid, sodium molybdate, compound sodium nitrophenolate, citric acid, ammonium citrate, magnesium sulfate and the balance of water; the nitrogen fertilizer film coating powder comprises vitamin B1, vitamin B6, vitamin B12, sodium selenite, calcium pantothenate, p-amino toluic acid, modified starch and cobalt chloride; the phosphorus fertilizer film coating liquid comprises animal amino acids, urea, zinc chloride, manganese chloride, boric acid, magnesium chloride and the balance of water; the potassium fertilizer granulation liquid comprises animal amino acids, urea, ferrous chloride, zinc chloride, manganese chloride, boric acid, ammonium citrate, compound sodium nitrophenolate, magnesium chloride and the balance of water; and the potassium fertilizer granulation powder comprises vitamin B1, vitamin B6, vitamin B12, calcium pantothenate and EDTA-2Na. The fertilizer has high utilization rate and the yield of crops is increased.

Owner:王意强 +1

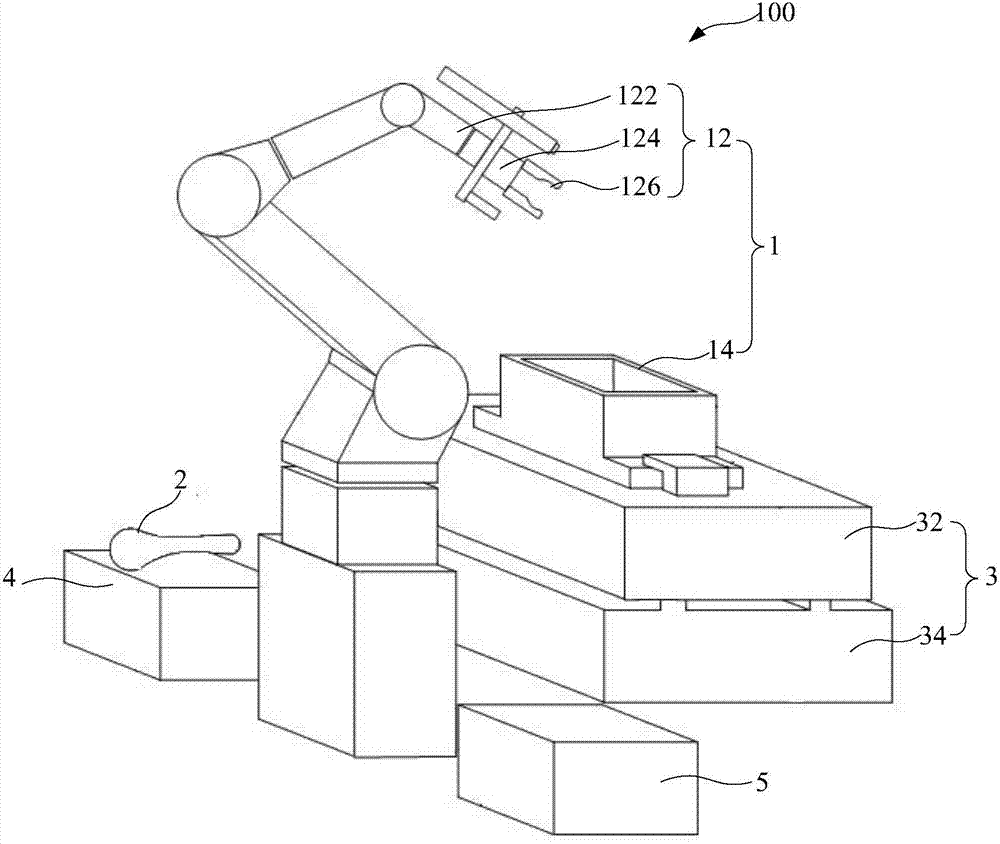

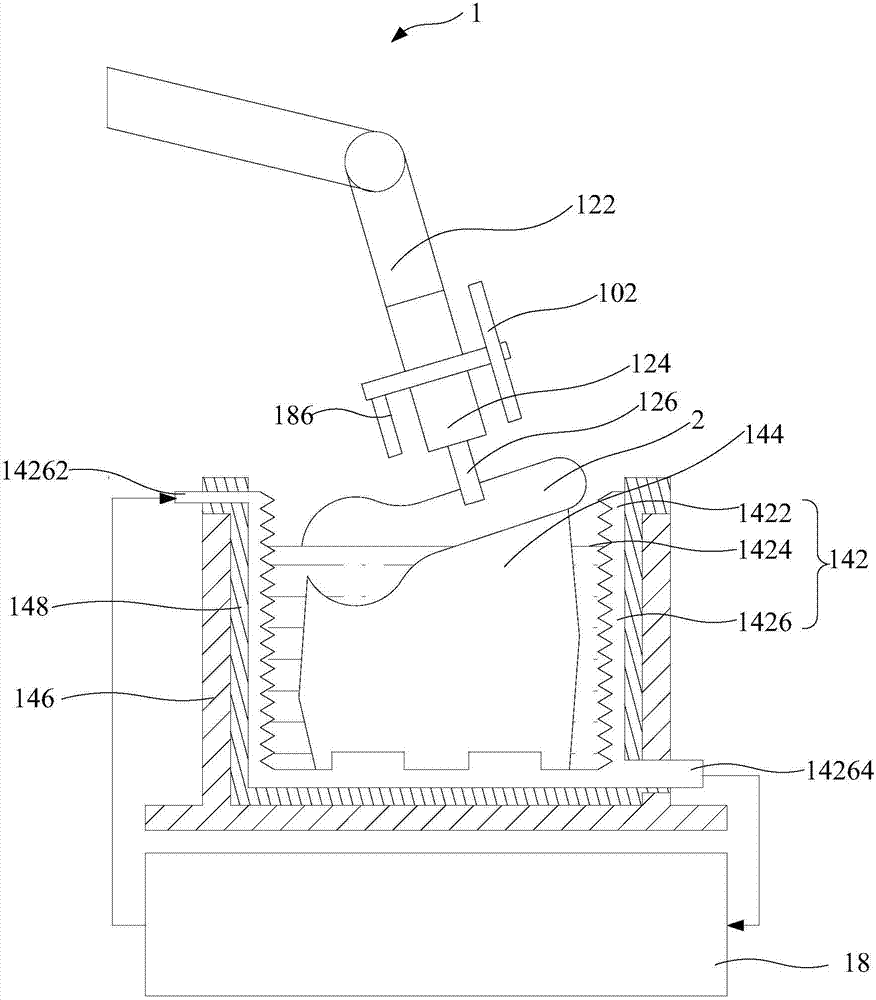

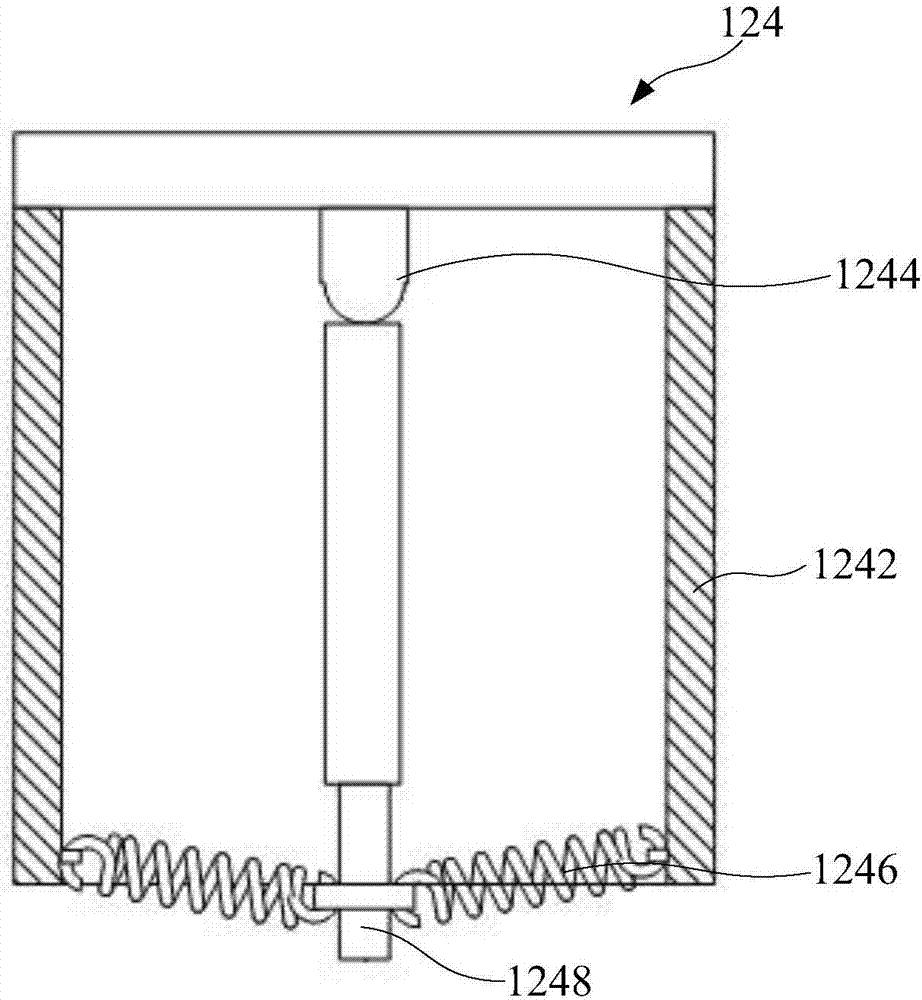

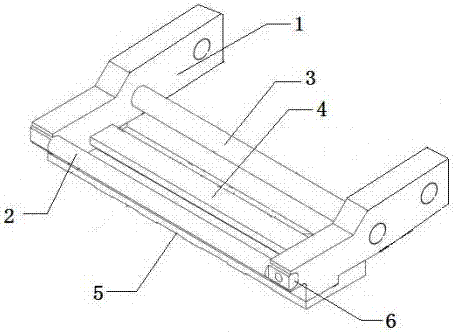

Clamp, machining assembly and application method of machining assembly

ActiveCN106862959AInfluence positioningImprove accuracyPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention provides a clamp, a machining assembly and an application method of the machining assembly. The clamp is matched with a machine tool for use and comprises a clamping mechanism and a fixing assembly. The clamping mechanism is arranged on the machine tool and comprises a mechanical arm, an elastic supporting assembly and a chuck. The elastic supporting assembly is connected with the mechanical arm and the chuck. The chuck is used for clamping a special-shaped part. The fixing assembly is installed on a workbench and comprises a container with the top being provided with an opening and a supporting piece. The container is used for containing a phase-change material, and the supporting piece is installed inside the container. When the chuck is used for clamping the special-shaped part, the special-shaped part can abut against the supporting piece through the opening position of the container according to the machining positioning requirements, and the special-shaped part, the supporting piece and the container are cured and fixedly connected together through the phase-change material. According to the clamp provided by the invention, the problem of posture uncertainty of the special-shaped part in the positioning process is avoided, the clamp with high fixing strength and rigidity and good machining datum repeatability is provided for finish machining, and the degree of using satisfaction by users is increased.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

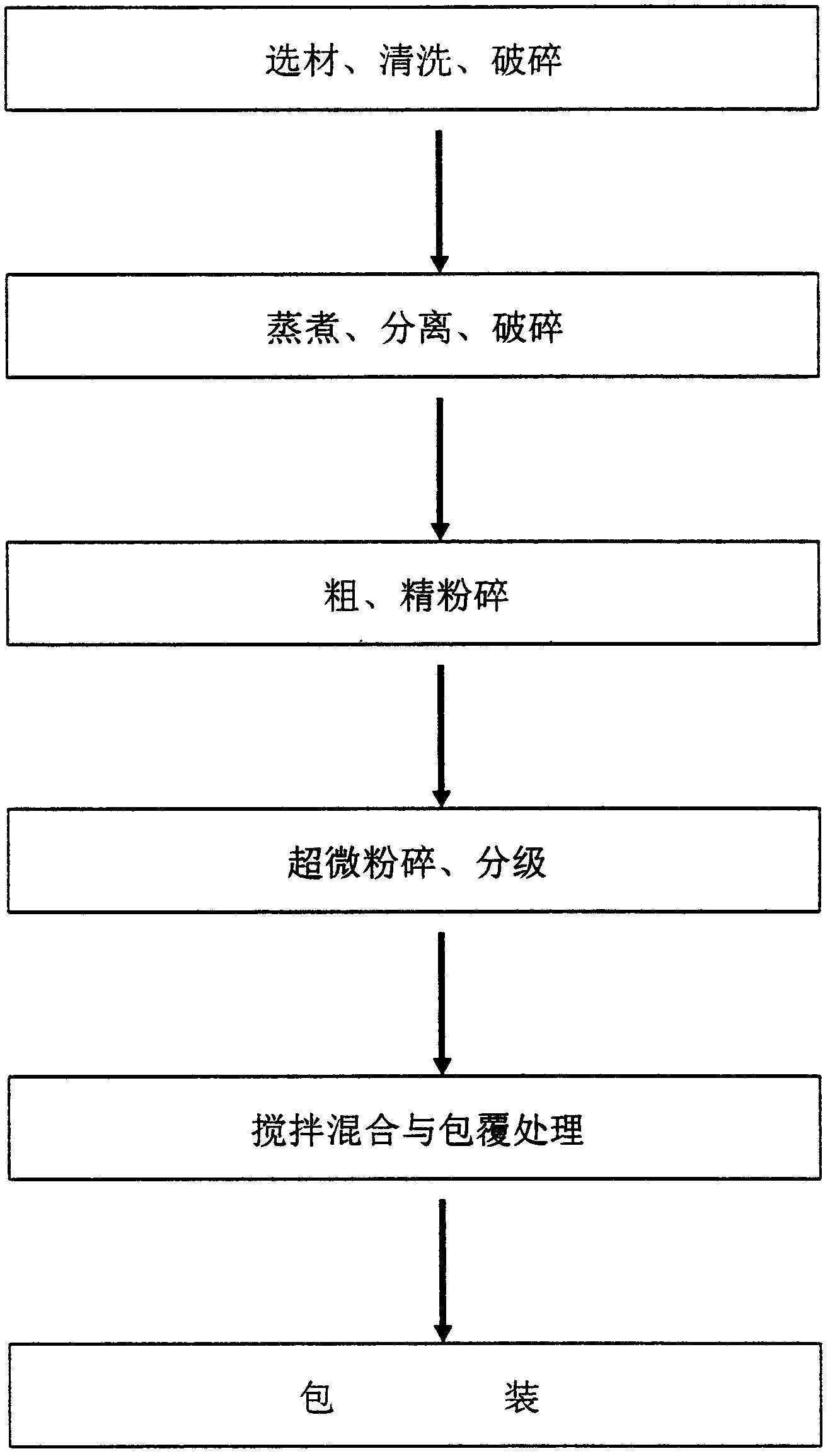

Animal bone calcium micro-nano powder and preparation method thereof

InactiveCN103251061AReduce solubilityNanoscaleMetabolism disorderUnknown materialsSolubilityMicro nano

The invention discloses an animal bone calcium micro-nano powder and a preparation method thereof. A calcium nutrient is a nanocapsule micropowder (10-1000nm) treating inorganic salts separated and extracted from animal bones as a raw material, is a decentralized ultrafine powder having the advantages of non-toxicity, tastelessness and no side effects, is used for the calcium nutrition supplement of a human body, the food nutrition reinforcement and medicinal applications, has an extremely high solubility and an extremely high bioactivity, improves the absorptivity of nutrients, is a new physical-state product, and has a calcium supplement effect comparable with that of organic acid calcium comprising milk and the like. The powder is obtained through utilizing fully-physical dry crushing, a high-speed airflow crushing technology and surface cladding decentralizing treatment, so the preparation method is the most advanced powder preparation technology at present, and has the advantages of maturation, reliability, suitableness for the industrialized production, and extremely high technological added values.

Owner:王宝林

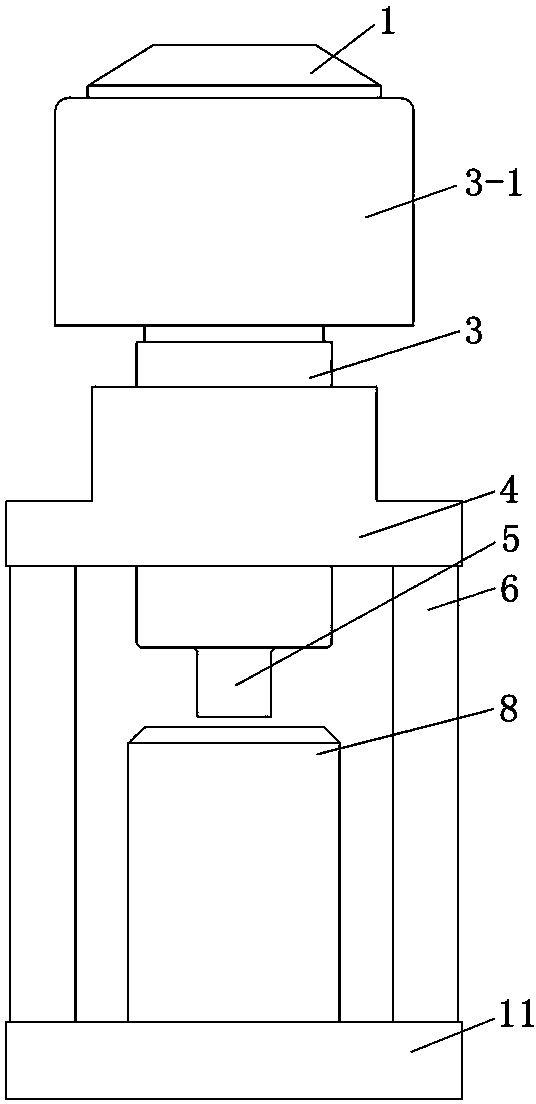

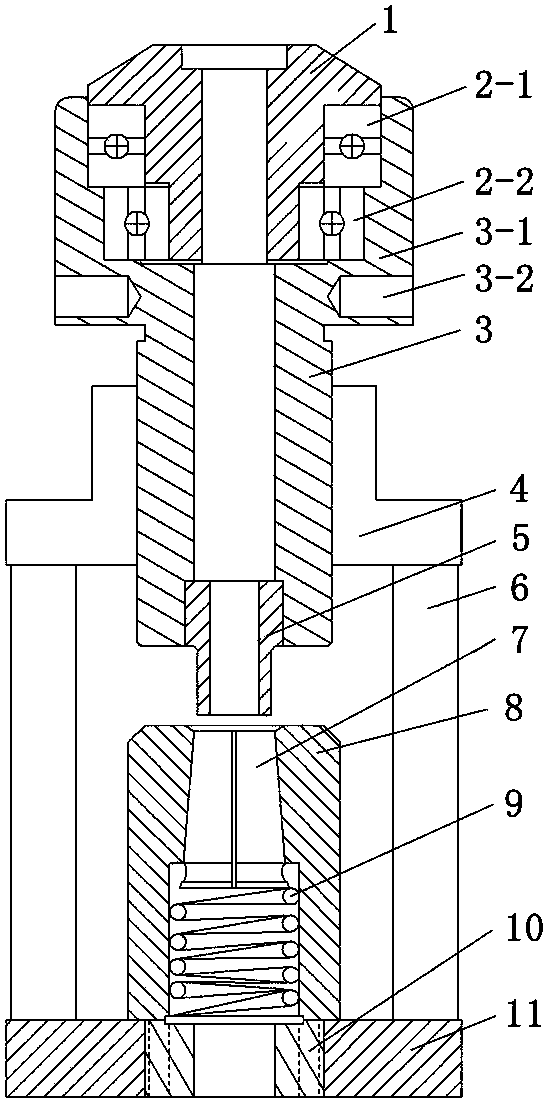

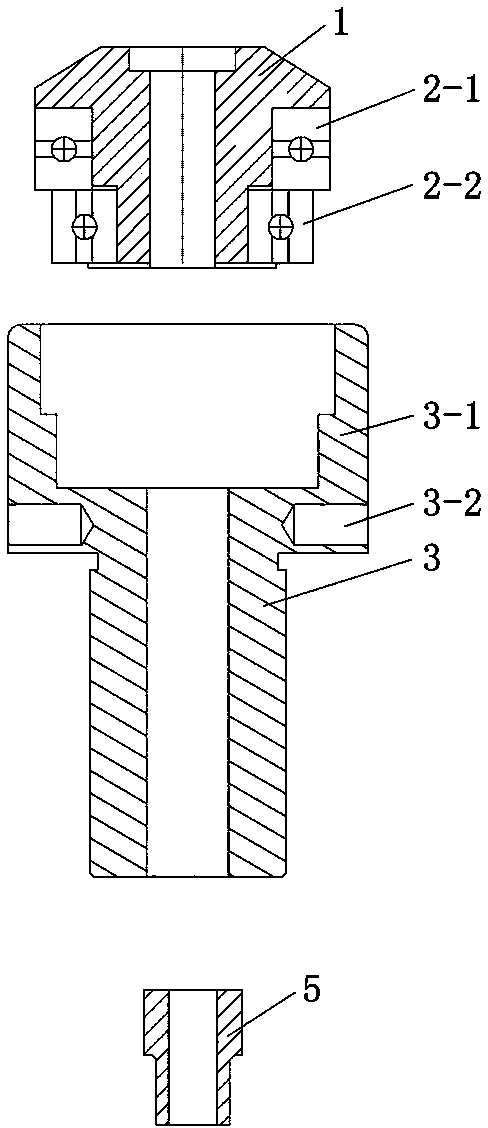

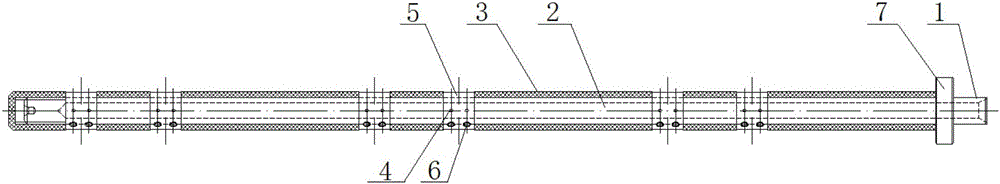

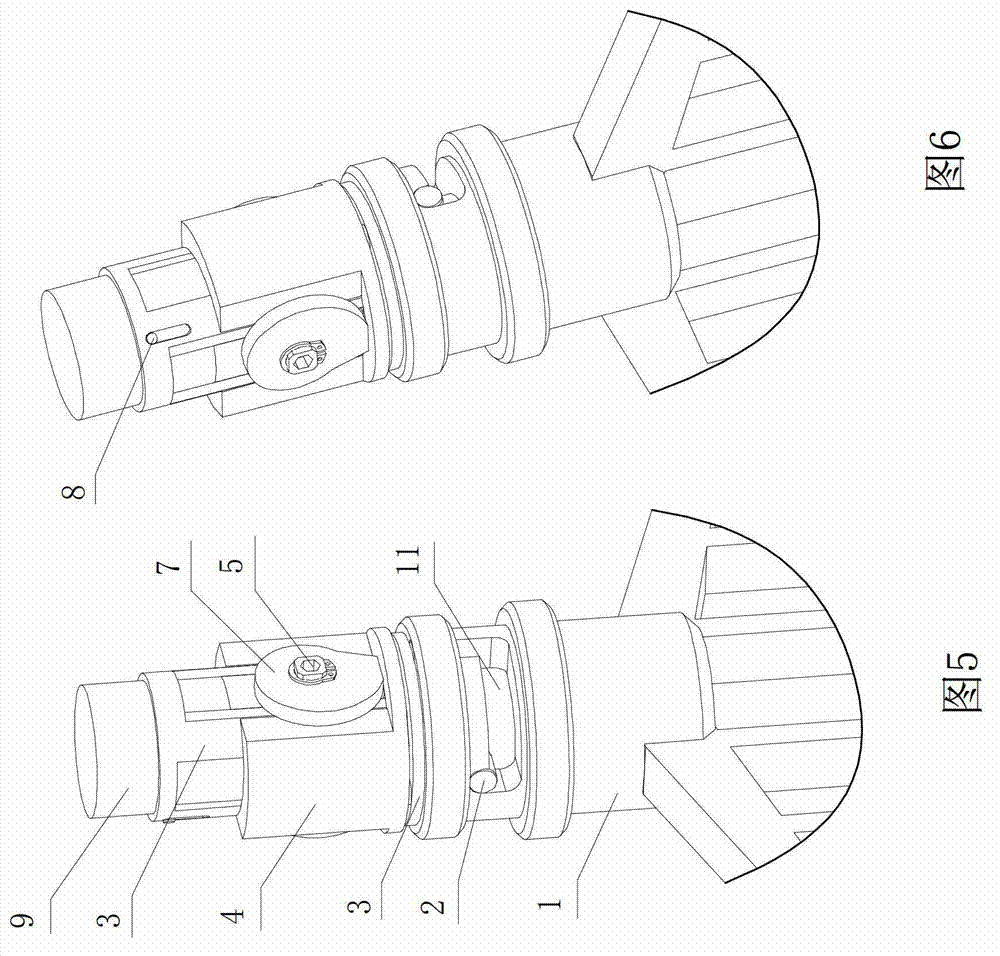

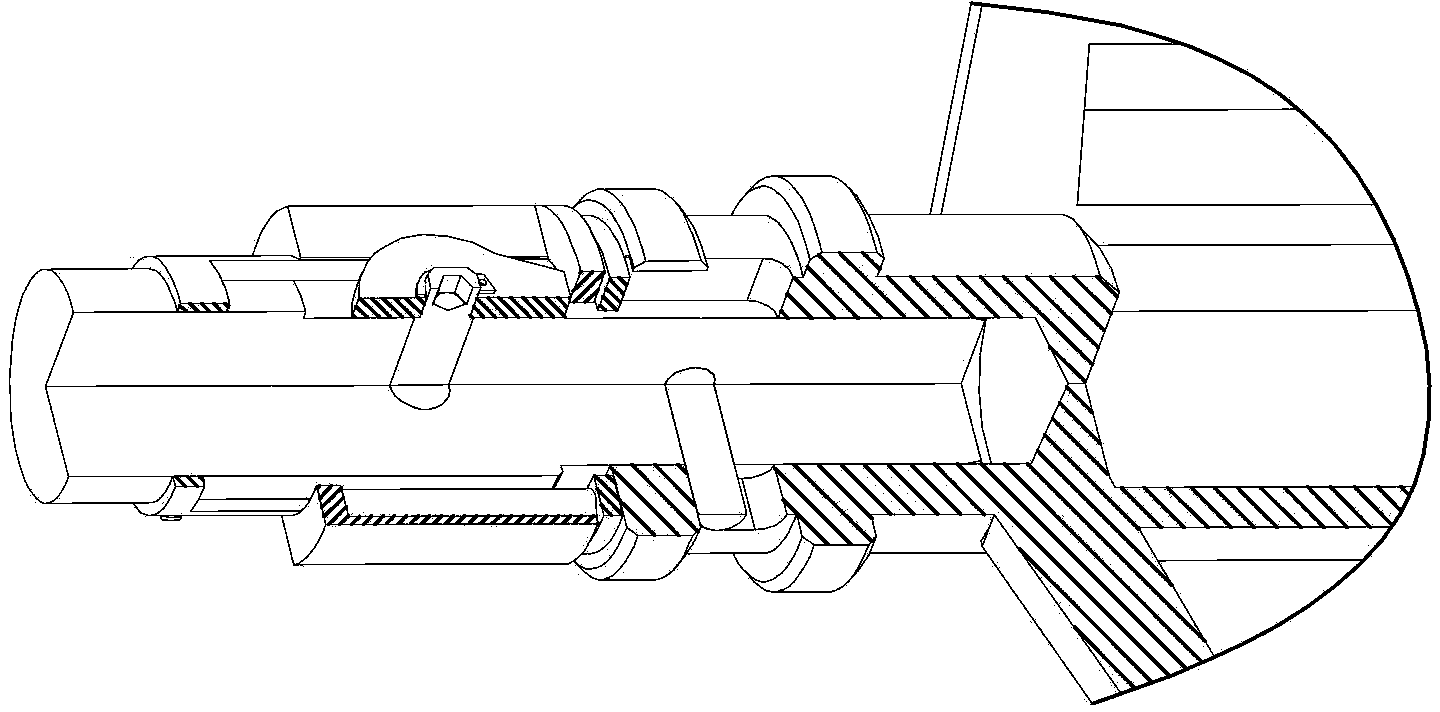

Portable pre-stressed tensioning jack

The invention discloses a portable pre-stressed tensioning jack, which relates to the technical field of pre-stressed tensioning construction. The portable pre-stressed tensioning jack comprises a run-through sleeve which is connected to a pedestal, wherein tool clamping pieces are clamped in the run-through sleeve; the small ends of the tool clamping pieces are close to the other end of the run-through sleeve; a spring for pressing the tool clamping pieces is arranged in the run-through sleeve and is butted against a pressing nut connected to the pedestal; the pedestal is connected with a fixing nut through a plurality of connecting rods; the fixing nut is in threaded connection with a run-through screw; an ejection sleeve which faces the tool clamping pieces is embedded in one end of the run-through screw; the other end of the run-through screw is connected with a supporting barrel; a movable ejection head which extends out of the barrel is inserted in the supporting barrel; a bearing is arranged between the side wall of the movable ejection head and the inner wall of the supporting barrel; and the movable ejection head and the supporting barrel are provided with through holes for allowing a pre-stressed steel strand to penetrate. Compared with the prior art, the portable pre-stressed tensioning jack has the advantages of simple structure, convenience in carrying, and safety, easiness and convenience in use and is suitable for the field of tensioning of small-tonnage steel strands, and no industrial energy is consumed during tensioning construction.

Owner:广西国森机械有限公司

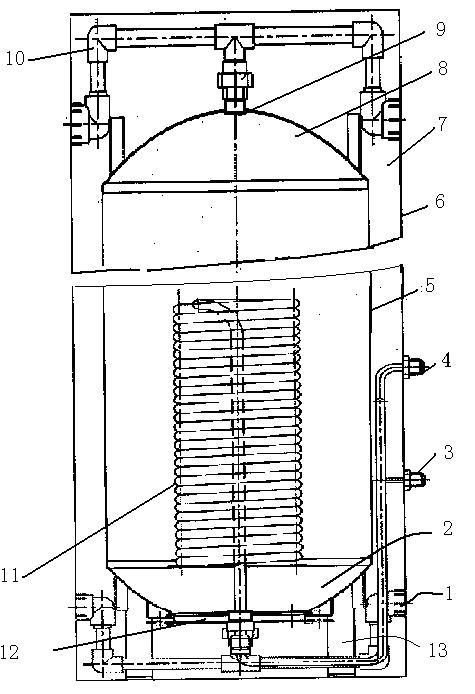

Single-end assembled heat-pump water heater water tank

InactiveCN102620429AGood installation quality and fastening effectImprove sealing performanceFluid heatersHeat pump water heaterEngineering

The invention discloses a single-end assembled heat-pump water heater water tank, which comprises a water tank liner, a heat exchanger, a heat-preserving layer and a shell, wherein the heat exchanger is arranged inside the water tank liner; a rotational molding layer is arranged on an inner surface of the water tank liner; a foaming heat-preserving layer and the shell are arranged on an outer layer of the water tank liner; the upper end of the water tank liner is welded with an integrated seal head; a hot water outlet pipe is arranged on the seal head; the lower end of the water tank liner is welded with a seal head flange; a sealing gasket and an end cover are arranged on the seal head flange; the end cover is sealed with the seal head flange through the sealing gasket; a water inlet hole and outlets of heat exchanger leading-out pipes are formed in the end cover; and in the heat exchanger, spiral ring pipes which have the same diameter are formed by winding copper pipes, the lower end of each spiral ring pipe directly leads out each leading-out pipe from a part below the end cover, and the upper end of each spiral ring pipe is bent downwards from the inner part of a spiral ring and leads out each leading-out pipe from the part below the end cover. The single-end assembled heat-pump water heater water tank is simple in structure, and the quality of the single-end assembled heat-pump water heater water tank can be greatly improved.

Owner:江苏翠波新能源发展有限公司

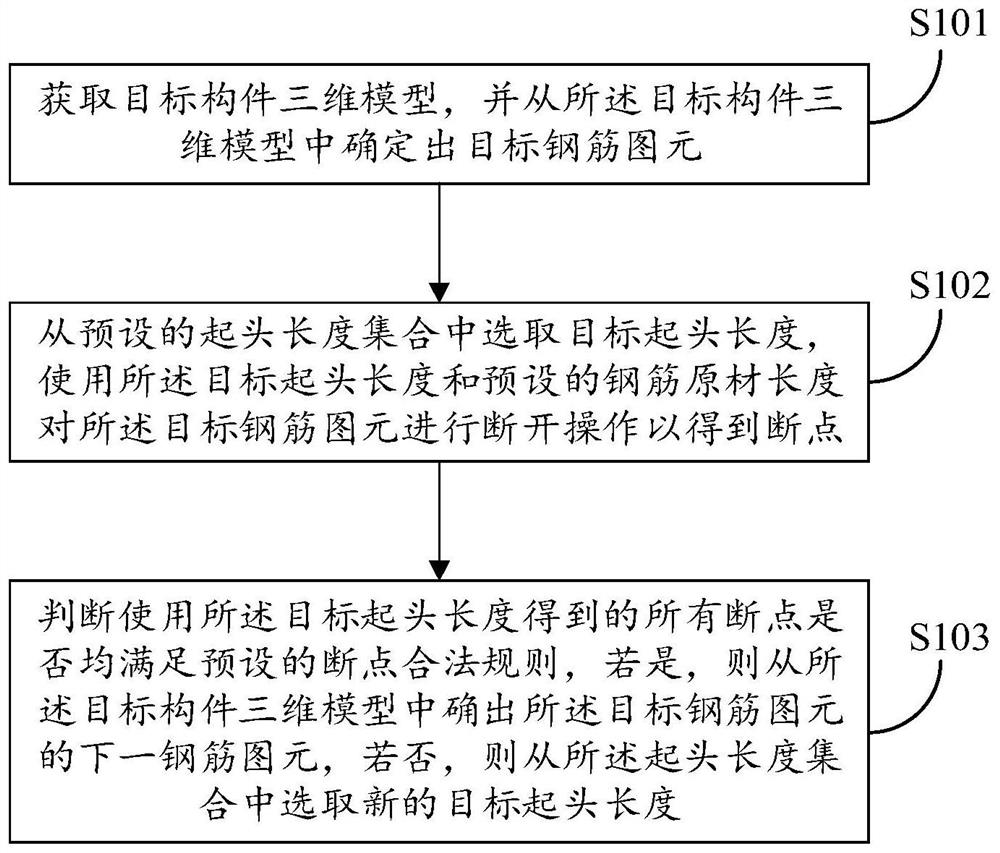

Method and device for determining breakpoint on reinforcing steel bar primitive, equipment and storage medium

PendingCN113887043AReasonable processingEasy to tieDesign optimisation/simulationSpecial data processing applicationsThree dimensional modelRebar

The invention discloses a method, device and equipment for determining a breakpoint on a steel bar primitive and a storage medium. The method comprises the following steps: obtaining a three-dimensional model of a target component, and determining a target steel bar primitive from the three-dimensional model of the target component; selecting a target starting length from a preset starting length set, and using the target starting length and a preset reinforcing steel bar raw material length to perform disconnection operation on the target reinforcing steel bar primitive so as to obtain a breakpoint; whether all breakpoints obtained by using the target starting length meet a preset breakpoint legal rule or not is judged, if yes, the next reinforcing steel bar primitive of the target reinforcing steel bar primitive is determined from the target component three-dimensional model, and if not, a new target starting length is selected from the starting length set; the technical problem that breakpoints cannot be automatically and accurately determined on continuous reinforcing steel bar primitives in the prior art is solved.

Owner:GLODON CO LTD

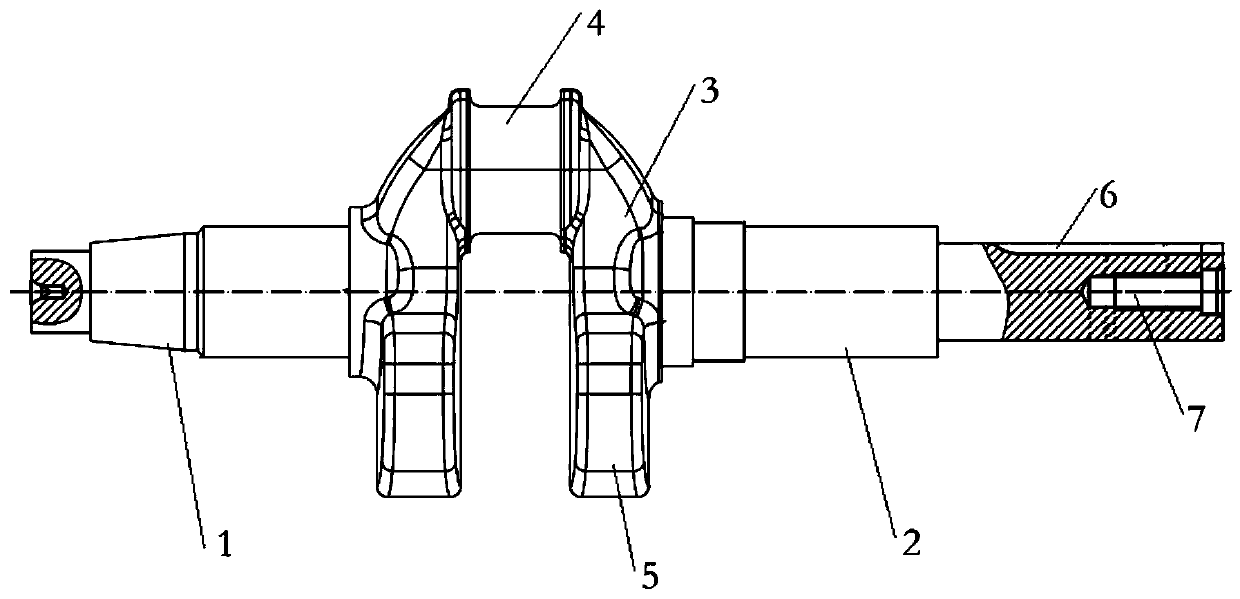

Crankshaft machining method

The invention discloses a crankshaft machining method. The crankshaft machining method comprises the step of acquiring a crankshaft blank, and further comprises the steps of a, conducting machining onthe outer end faces of a crankshaft input shaft section and an output shaft section to obtain center holes; b, conducting rough turning and finish turning on the crankshaft input shaft section and conducting rough turning and finish turning on the crankshaft output shaft section; c, turning the inner sides of two crank arms and a main journal to enable the length of the part, between the inner side faces of the two crank arms, of the main journal to be matched with the designed length; d, machining key grooves of the crankshaft output shaft section and the input shaft section; e, conducting quenching machining on the main journal on a crankshaft; f, conducting straightening treatment on the quenched crankshaft; g, conducting drilling, broaching and tapping at the position corresponding toa center hole of the outer end of the crankshaft output shaft section to obtain a threaded hole; h, conducting thread rolling machining on the small end of the crankshaft input shaft section; and i,conducting grinding machining on the big end of the crankshaft input shaft section and the outer circumferential surface of the big end of the output shaft section. The crankshaft machining method hasthe advantages that the machining efficiency can be improved, and the manufacturing cost can be reduced.

Owner:CHONGQING MEIXIN YINGSHEN MACHINERY CO LTD

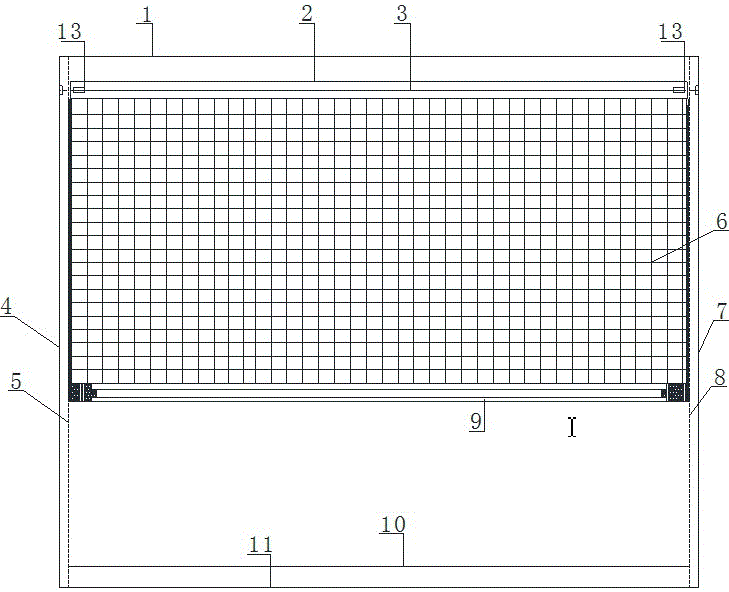

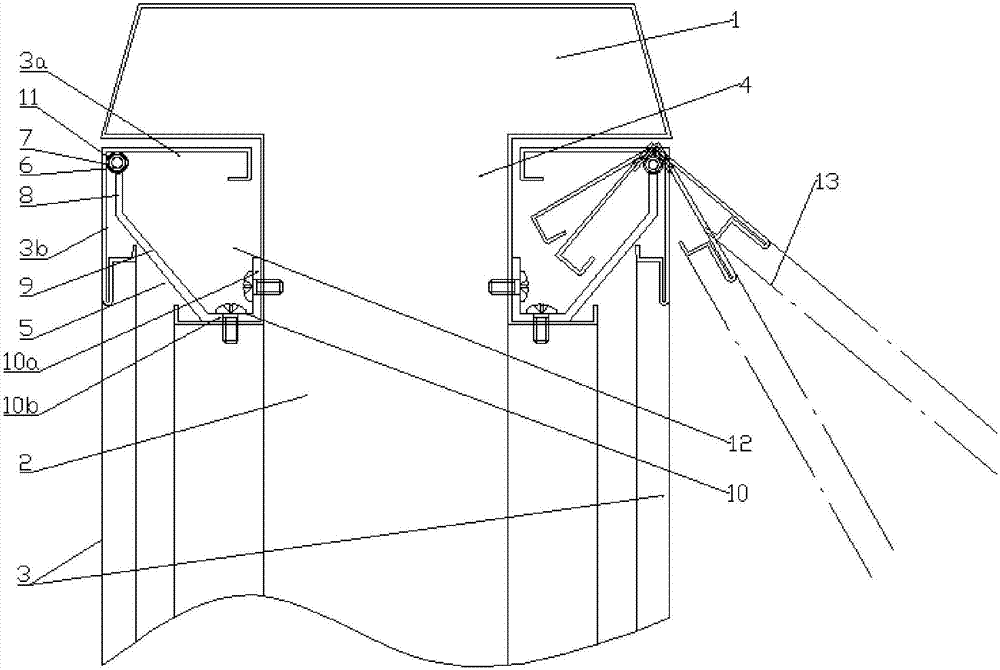

Solar energy-saving heat-insulating window capable of collecting heat and sheltering from sunshine

ActiveCN106351556ALower heat transfer coefficientLess heat lossSolar heating energyFireproof doorsLower borderRemote control

The invention provides a solar energy-saving heat-insulating window capable of collecting heat and sheltering from sunshine. A window frame of the heat-insulating window is located on the outer wall of a corresponding window, a heat-insulating shutter protecting tube is fixed in an upper border of the window frame, two rotating shafts connected with a heat-insulating shutter are arranged in the heat-insulating shutter protecting tube, and remote-control motors are arranged on the rotating shaft I and rotate to drive the rotating shaft II to rotate; a stainless steel solar heat collector is arranged slantwise downwards outside the upper border of the heat-insulating shutter protecting tube; the heat-insulating shutter moves vertically through a left guide rail and a right guide rail arranged in a left border and a right border of the window frame, a pulling bar with the identical width to that of the heat-insulating shutter is fixed at the tail end of the heat-insulating shutter, and the pulling bar is connected with a locating bar, fixed on the lower border, through magnetic buckles and plastic suckers. The heat-insulating window is simple in structure and high in seal property, further improves the heat-insulting property of doors and windows, can shelter from the sunshine and produce hot water by the aid of solar energy, is applicable to cold dispelling and sunstroke prevention for residents and is energy-saving.

Owner:TAIYUAN UNIV OF TECH

Herb tea for treating wind-cold-dampness cold

InactiveCN1634468AReasonable formulaReasonable processingUnknown materialsAntiinfectivesHypericum perforatumMedicine

The invention provides a compound collunarium oil and preparation method, wherein the preparation is prepared from Xanthium sibiricum, flower bud of lily magnolia, centipeda, asaryl, dahurian angelica root, sweet wormwood, astragalus root, baikal skullcap root, alkanna tinctoria, ledebouriella root, Hypericum perforatum and boneol according to a finite proportion through immersion with vegetable oil.

Owner:蓝子花

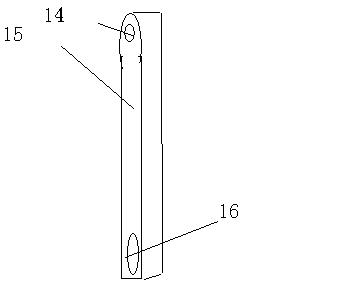

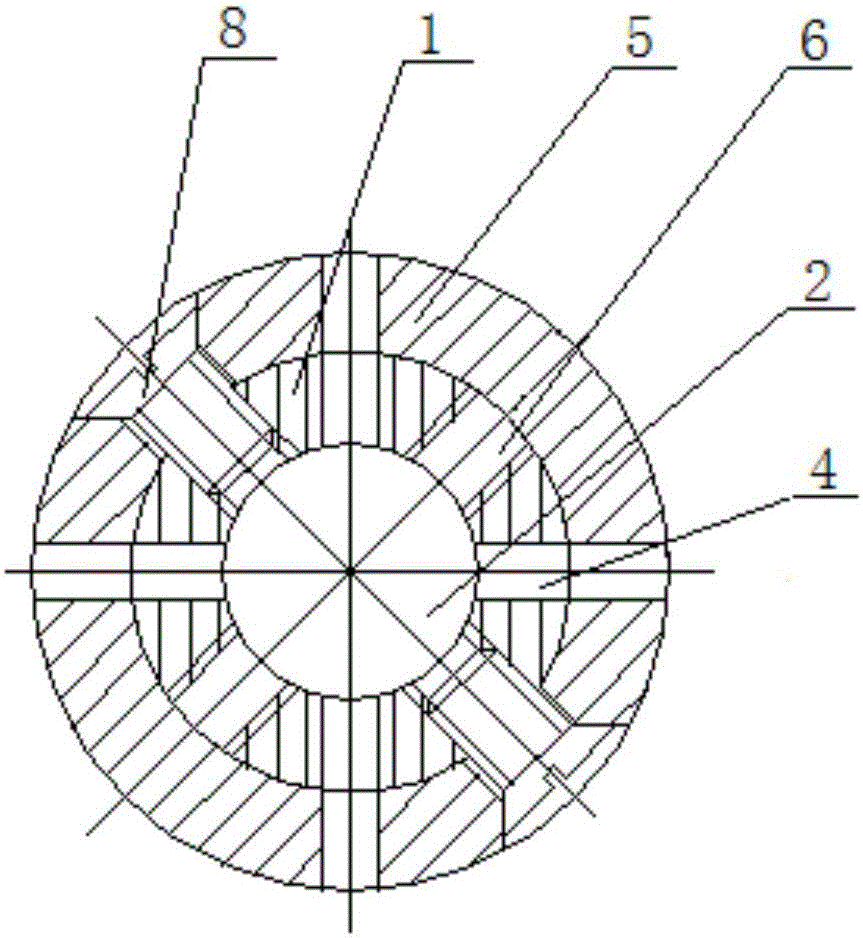

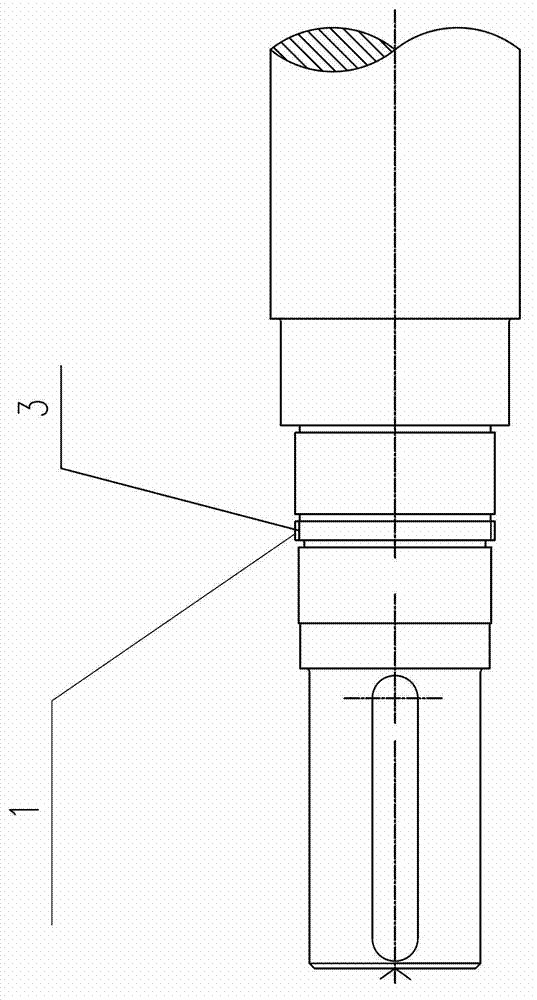

Electrode bar for removing burrs through electrolyzing

The invention discloses an electrode bar for removing burrs through electrolyzing. The electrode bar comprises a cylindrical electrode pole body; the electrode pole body is internally provided with an electrolyte cavity; the electrode pole body is provided with at least one section of electrolysis part capable of spraying out electrolyte; the section of electrolysis part is provided with at least one circle of electrolysis unit capable of being distributed along a rotary direction; the electrolysis unit comprises a plurality of liquid spraying holes which are communicated with the electrolyte cavity formed in the same circumference; an electrode coil adaptive to the electrolysis unit further sleeves the electrolysis part; an insulating structure is arranged on an outer surface of the electrode pole body. The electrode bar provided by the invention is reasonable in structure, simple to manufacture and rapid in burr removing speed; the burrs are sufficiently removed and the roughness is effectively guaranteed.

Owner:GUANGXI YUCHAI MASCH CO LTD

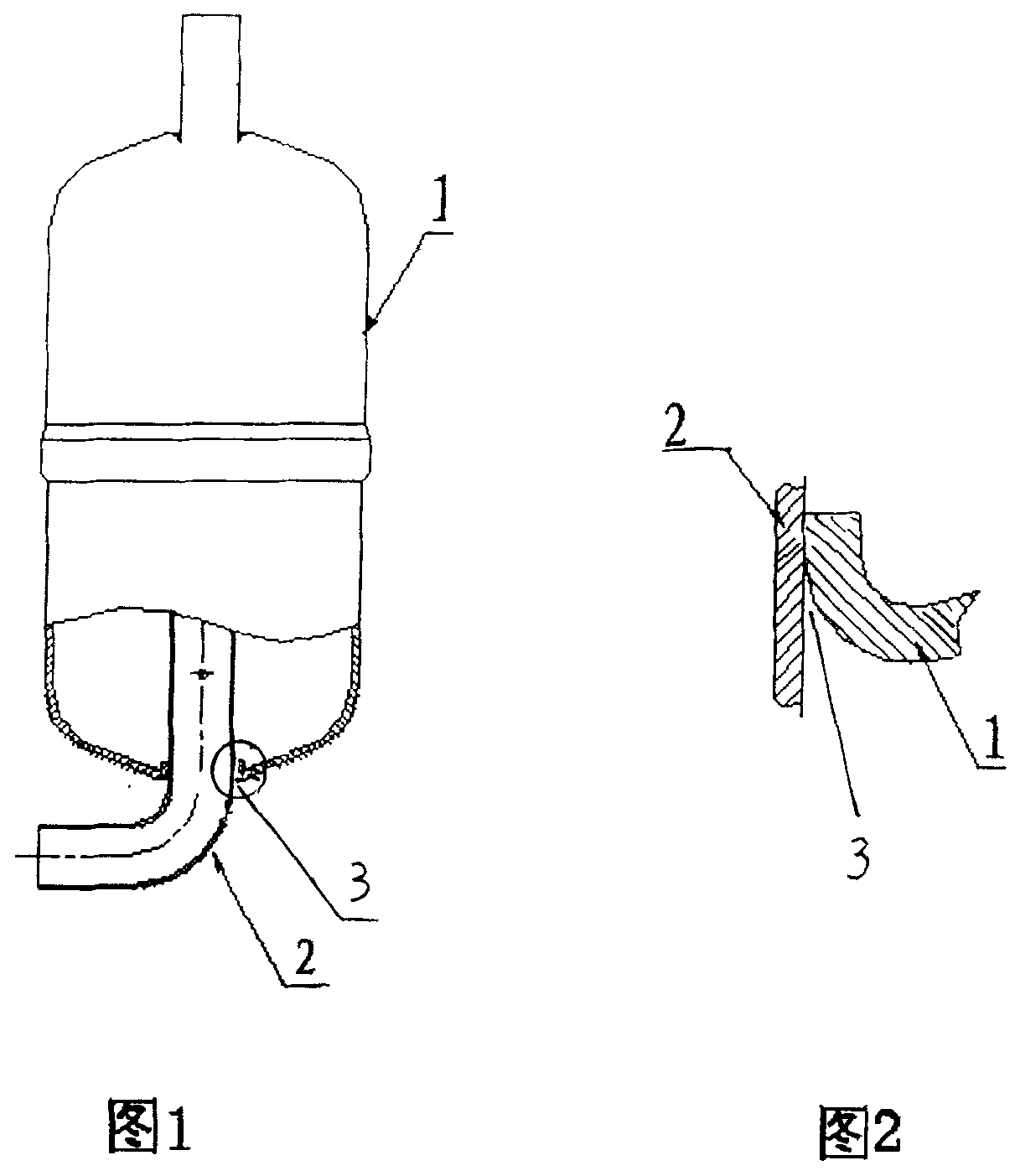

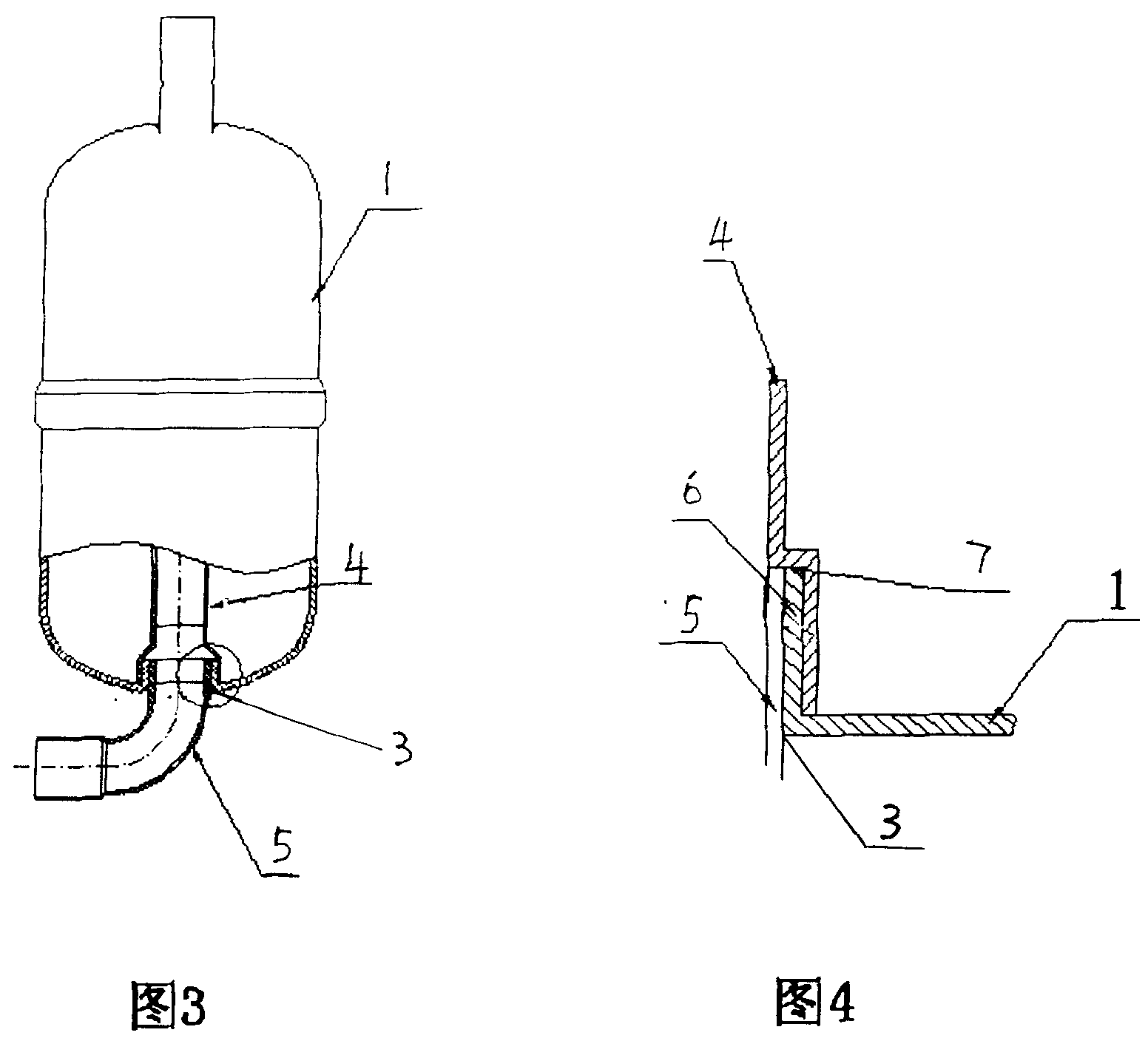

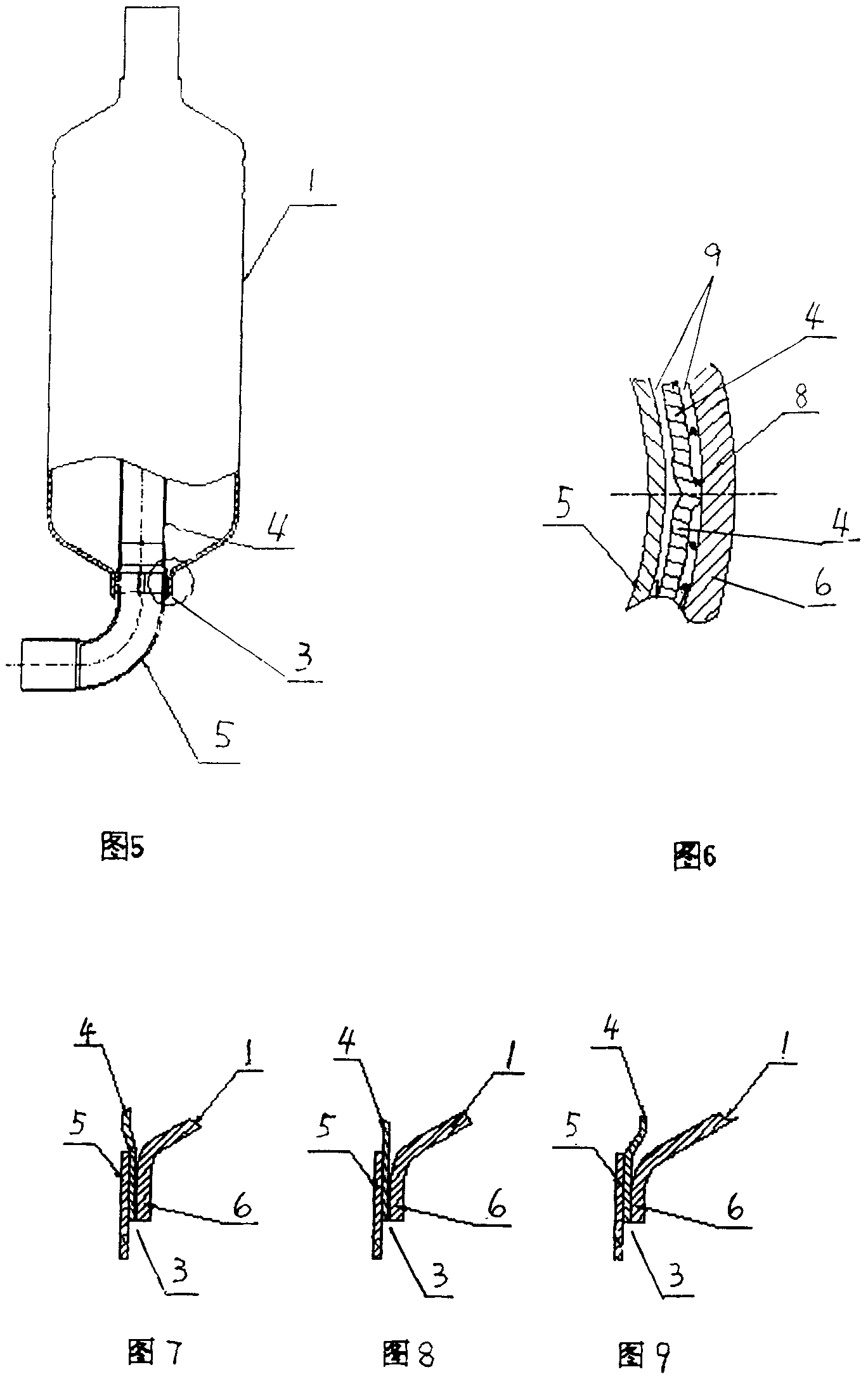

Machining process of liquid pipe for gas-liquid separator

InactiveCN1772432BSolve the problem of poor permeabilityAvoid eccentricityOther manufacturing equipments/toolsGas flame welding apparatusInterference fitVapor–liquid separator

The machining process of liquid pipe for gas-liquid separator includes setting liquid outlet in the bottom of the liquid storage unit, forming downward vertical turned edge, expanding the inner iron tube, pressing the inner iron tube into the turned edge, setting three or four raised ribs with upper flange in the expanded part of the inner iron tube for interference fitting between the inner irontube and the tubular turned edge of the liquid storage unit body while retaining welding interval, setting the outer copper tube inside the expanded port of the inner iron tube and final welding to form one integral. The machining process of the present invention is simple, reasonable, high in production efficiency and high welding quality.

Owner:江门市森德制冷器材有限公司

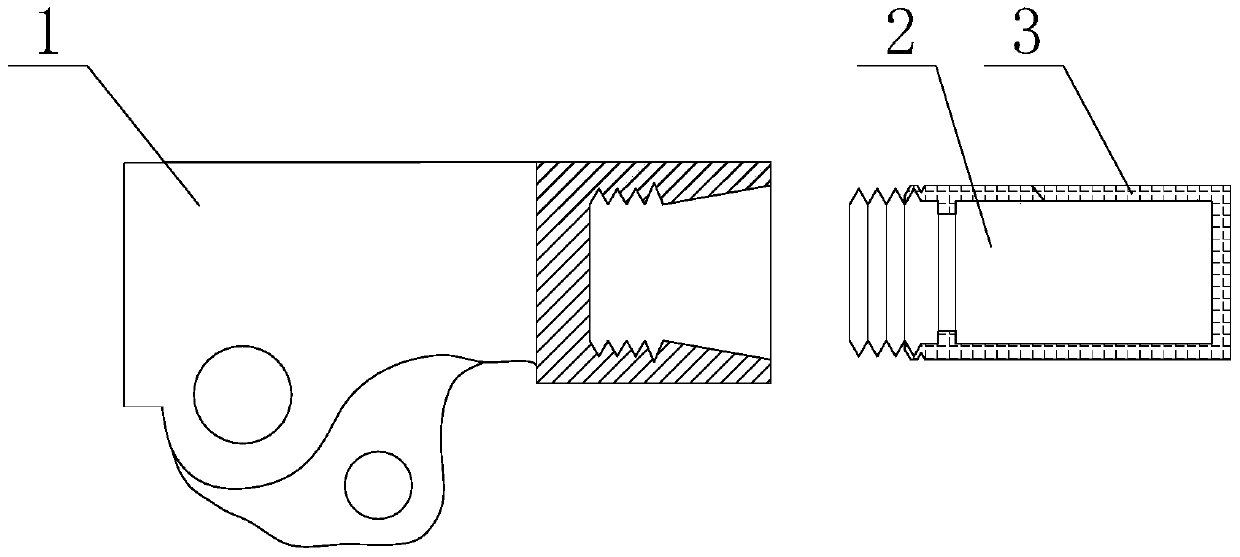

A pressing hand assembly for a horizontal jack

The invention discloses a pressing handle assembly for a horizontal lifting jack. An outer thread is arranged on the outer periphery of the end of a handle. An inner thread is arranged in a columnar cavity of a pressing handle body, and the handle is sleeved with a handle sleeve. During installation, the handle sleeve is arranged on the outside of a handhold part of the handle in a sleeving mode and fixed to the handle through a clamping grove and a protrusion. The handle is installed in the columnar cavity through matching of the inner thread and the outer thread, and the opening end of the handle sleeve is clamped between the handle and the columnar cavity. Fixation and disconnection of the handle and the pressing handle body can be achieved only by rotating the handle by several circles, and the handle sleeve does not fall off the handle in use. The pressing handle assembly for the horizontal lifting jack is simple in structure and reasonable in design, the fixation and disconnection of the handle and the pressing handle body can be achieved only by rotating the handle by several circles by an operator, and the handle can be easily fixed to or drawn out of the pressing handle body. The pressing handle assembly for the horizontal lifting jack is easy to operate, reasonable in structure, high in motion reliability, capable of guaranteeing use safety and meanwhile easy to machine and low in cost.

Owner:ANHUI TONGRUN AUTO ACCESSORY

Waterproof connector for electronic products and machining method thereof

InactiveCN110444957AImprove waterproof performanceImprove yield rateEngagement/disengagement of coupling partsContact member cases/bases manufactureEngineeringScrew thread

The invention discloses a waterproof connector for electronic products and a machining method thereof, and belongs to the technical field of waterproof connectors. The waterproof connector comprises amale head and a female head, wherein the outer walls of the male and female heads are both in threaded connection with a waterproof connecting sleeve; the junction of the male head and the waterproofconnecting sleeve is in screw-thread fit with an upper annular sleeve; and an upper retaining ring is fixed to the upper-end inner wall of the waterproof connecting sleeve. The method comprises manufacturing the waterproof connecting sleeve: soldering the upper retaining ring to the upper end of the upper-end inner wall of the waterproof connecting sleeve, providing the inner wall of the waterproof connecting sleeve with internal threads, then soldering an annular pressing plate to the lower end of the inner wall of the waterproof connecting sleeve; and machining the male head: engaging the upper part of the outer wall of the male head with the upper annular sleeve, placing the male end on a thread milling machine to provide the outer wall of the upper annular sleeve with external threads, and attaching an upper sealing gasket to the upper end of the upper annular sleeve. The waterproof connector is ingenious in design, reasonable in structure, reasonable to machine, low in machiningcost, wide in application range, and for popularization and use.

Owner:PUTIAN UNIV

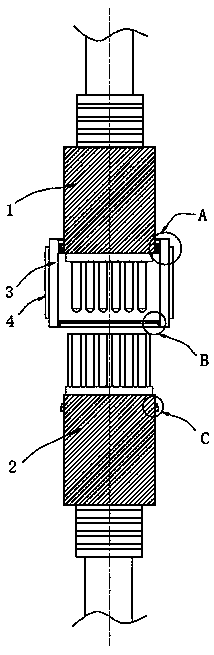

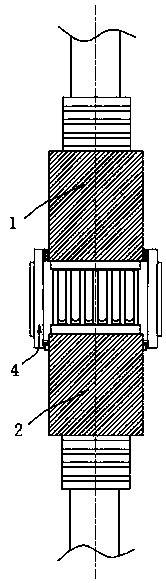

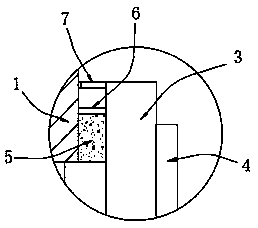

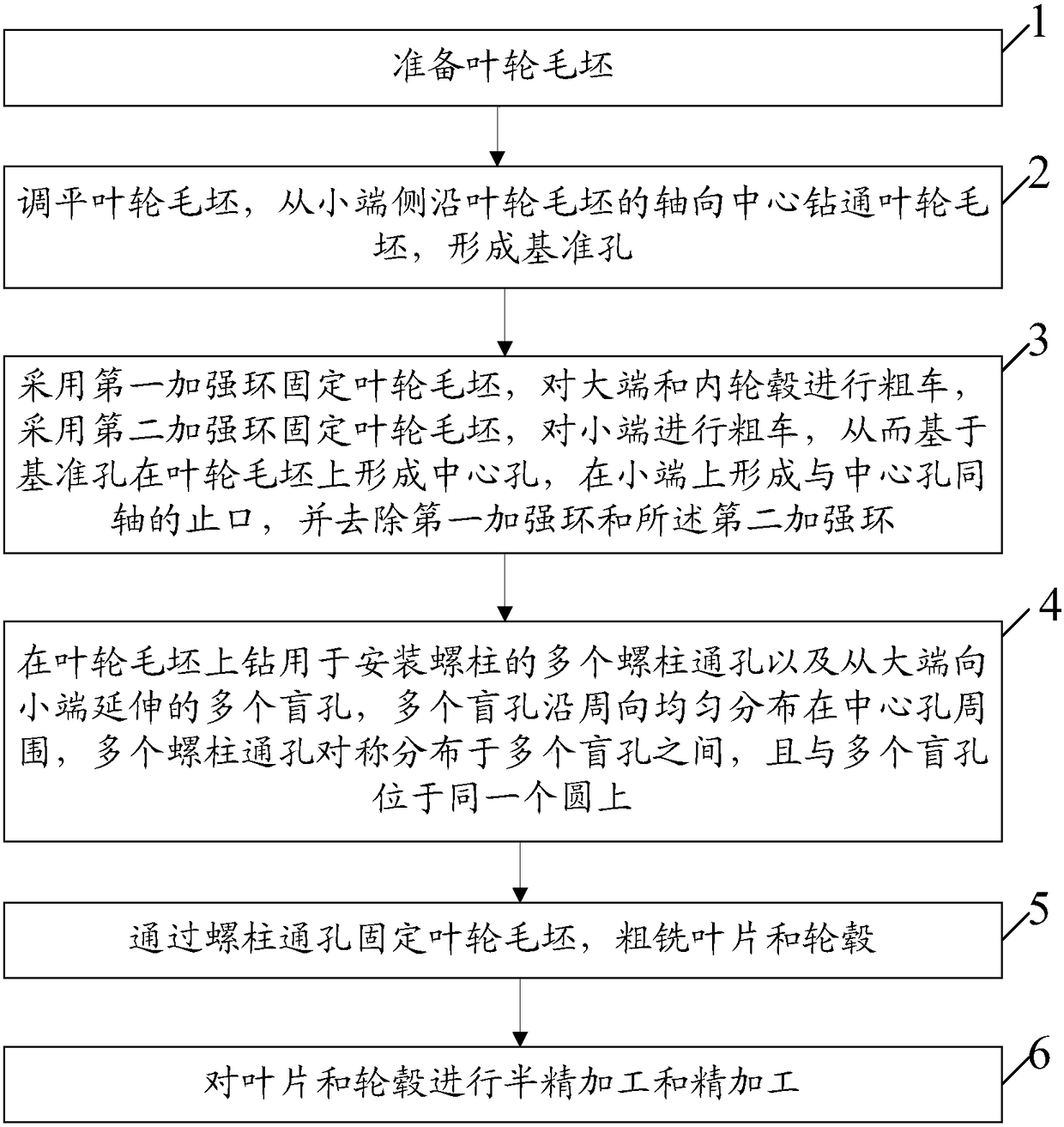

A method of processing an impeller

The invention discloses an impeller machining method, and belongs to the field of impeller machining. The impeller machining method comprises the following steps that an impeller blank is prepared; the impeller blank is leveled, and the impeller blank is drilled through from the small end side along the axial center of the impeller blank to form a basic hole; the impeller blank is fixed through a first reinforcing ring, the large end and an inner hub are roughly turned, the impeller blank is fixed through a second reinforcing ring, the small end is roughly turned, and accordingly a central hole is formed in the impeller blank based on the basic hole, a spigot coaxial with the central hole is formed in the small end, and the first reinforcing ring and the second reinforcing ring are removed; a plurality of stud through holes and a plurality of blind holes are drilled in the impeller blank; the impeller blank is fixed through the stud through holes, and blades and a hub are roughly milled; and semi-finished machining and finished machining are carried out on the blades and the hub. The method can be used for machining an impeller of a large-power water-spraying propelling device.

Owner:WUHAN MARINE MACHINERY PLANT

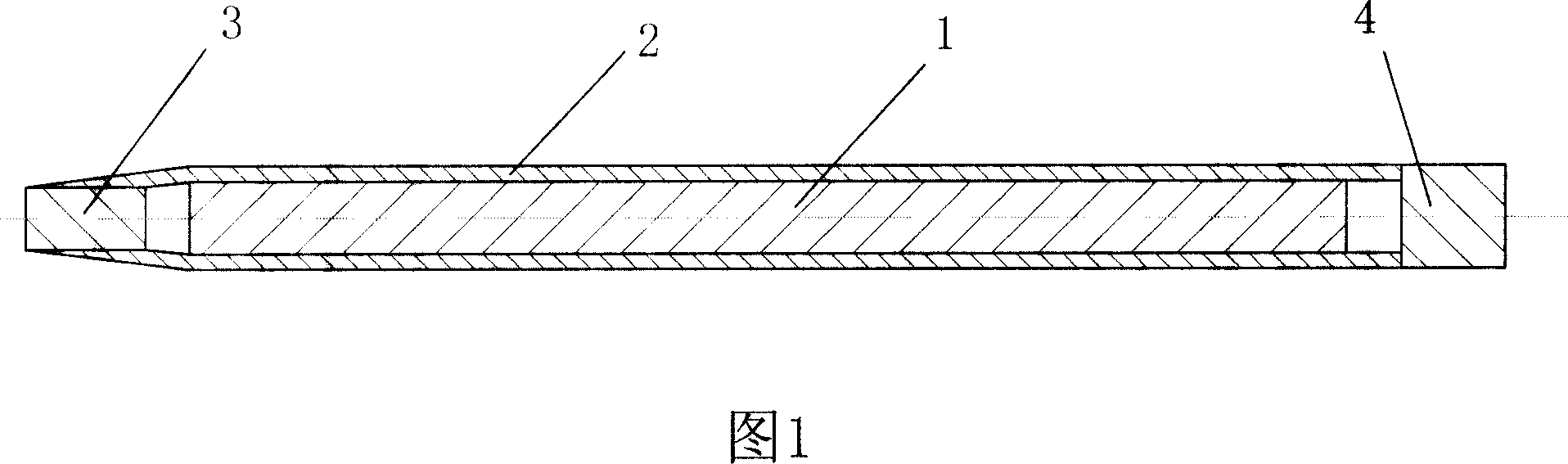

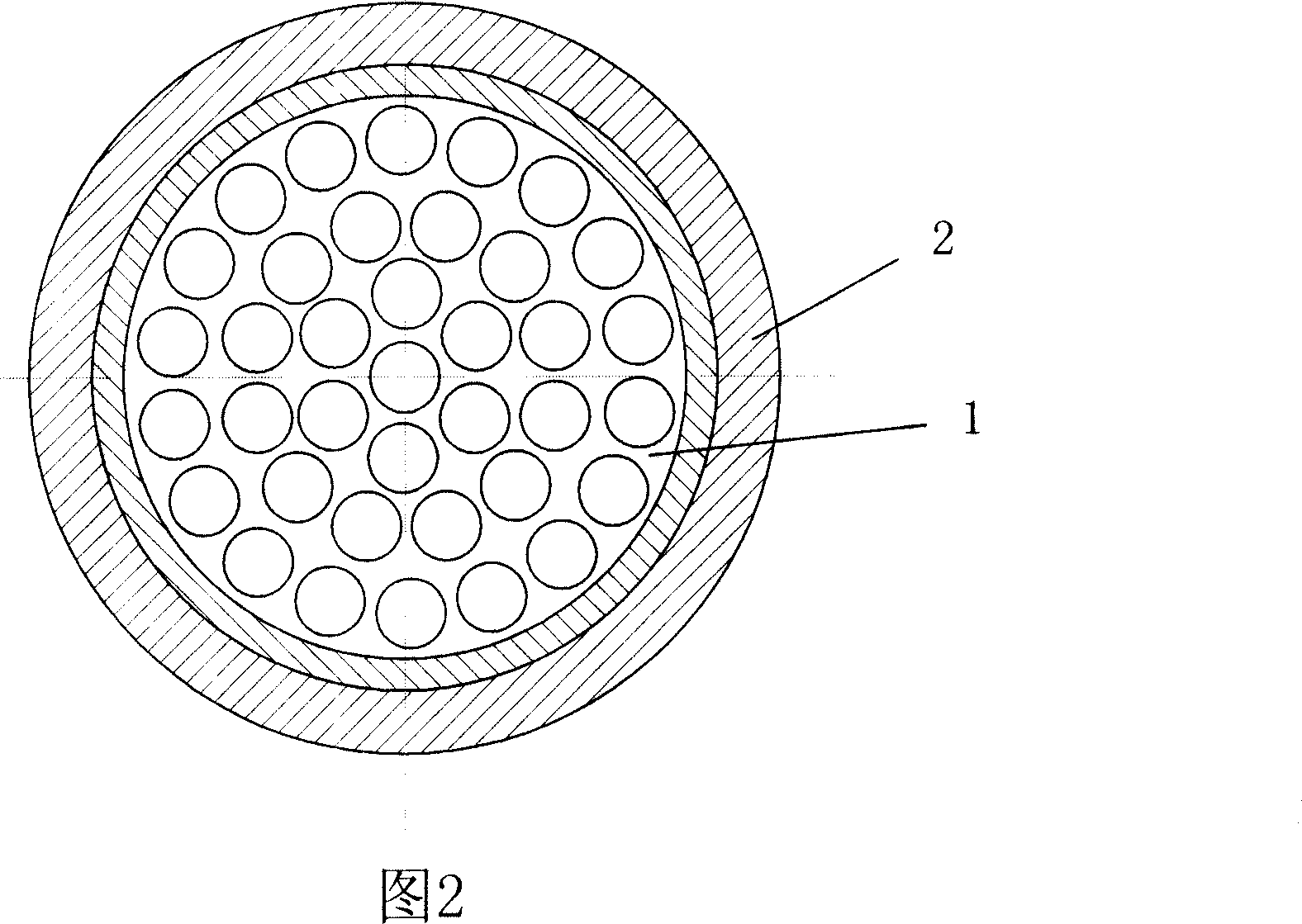

Method for preparing high temperature super conductive conductor

InactiveCN101051540AImprove deformationHigh strengthSuperconductors/hyperconductorsCircuit arrangementsHigh-temperature superconductivityMetal

Owner:INNOVA SUPERCONDUCTOR TECH

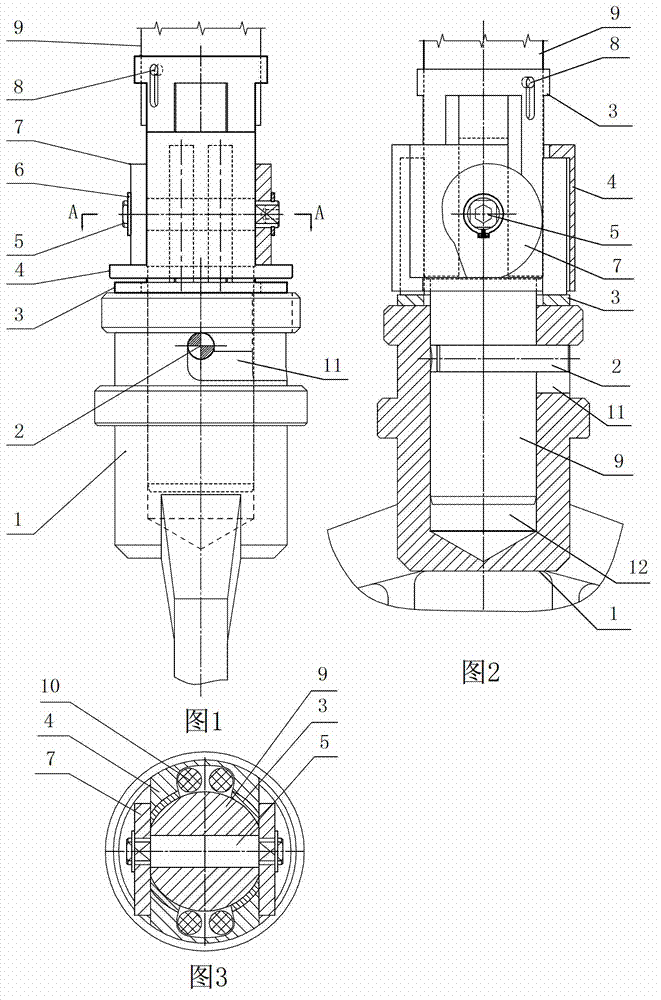

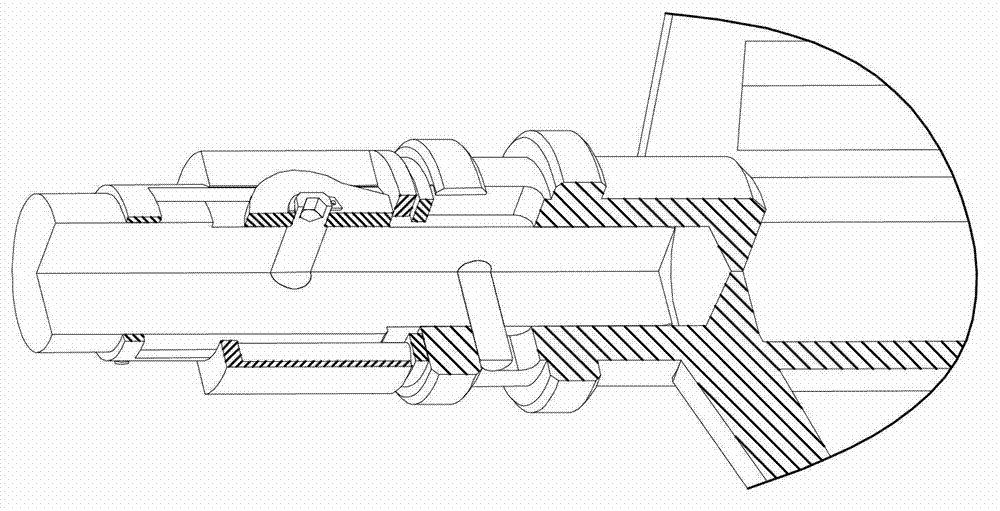

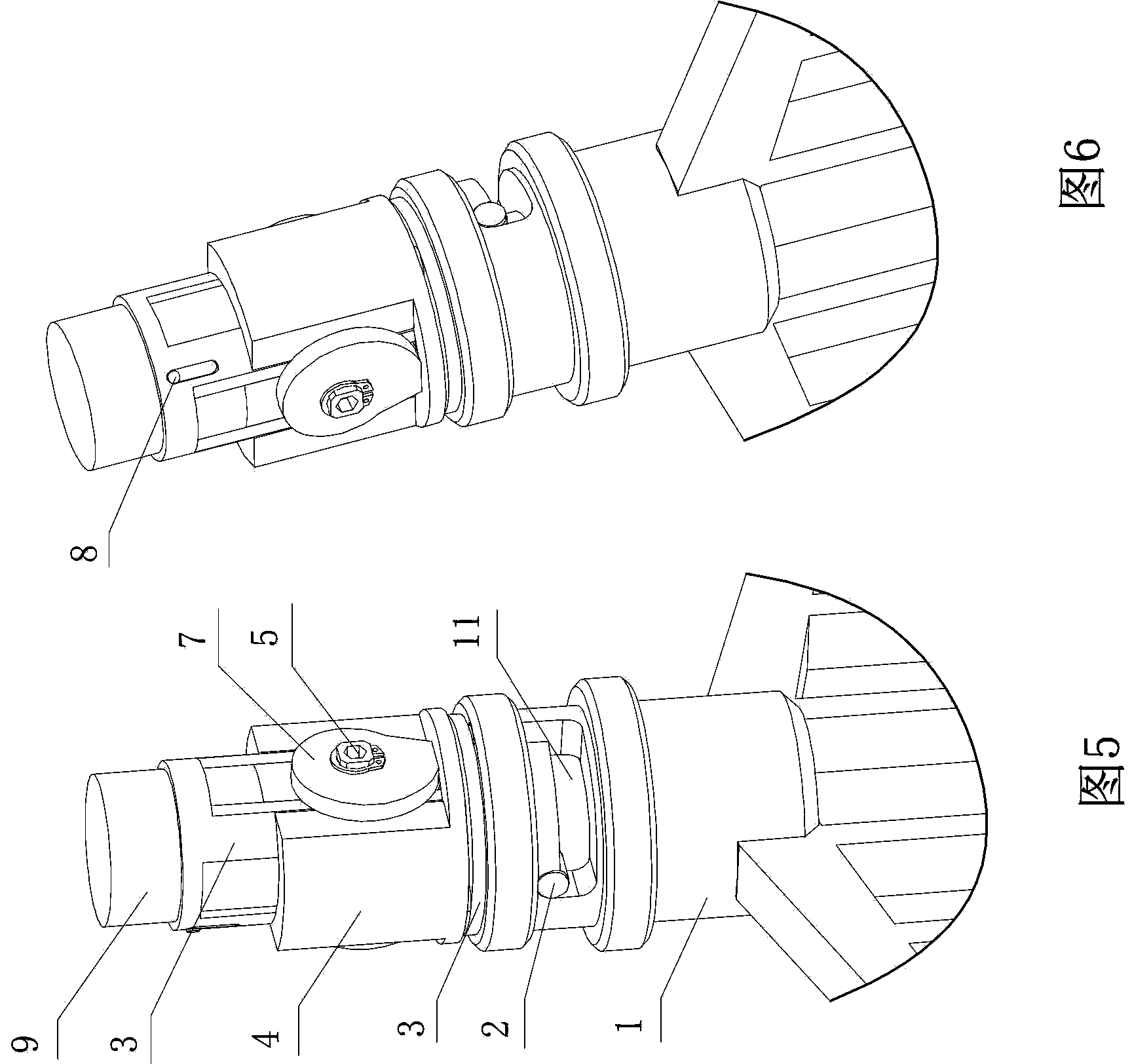

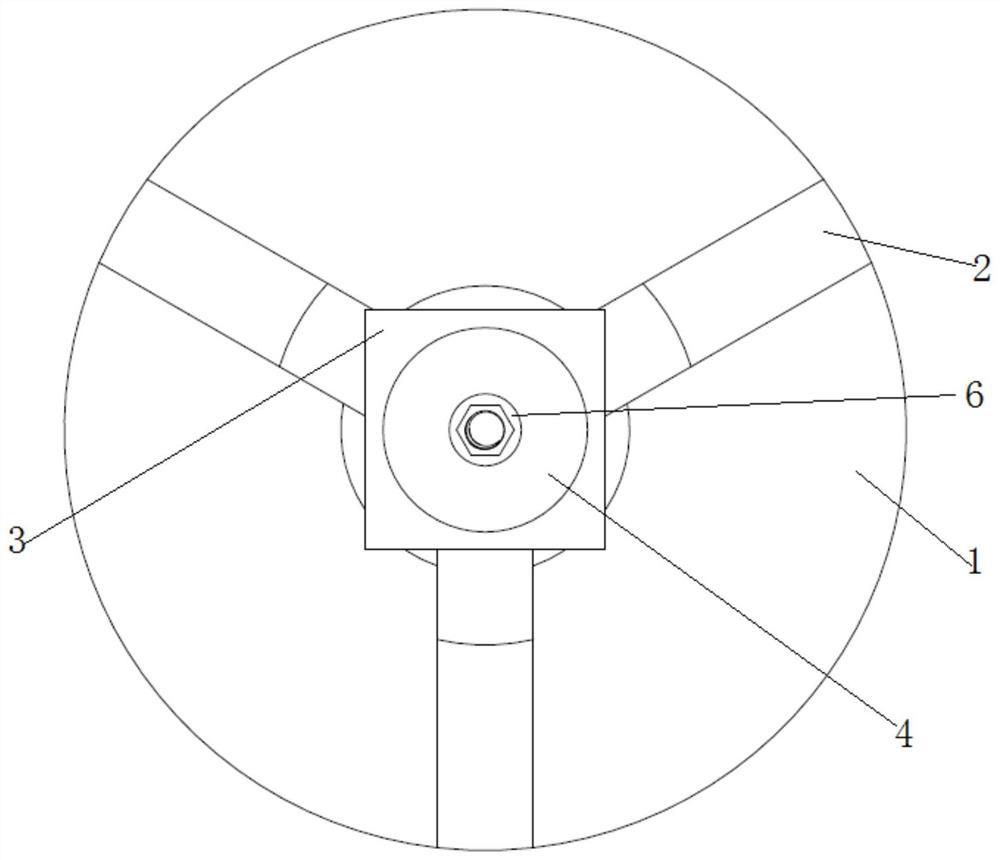

Rapid locking mechanism for stirring paddle

ActiveCN102814141AReliable torque transmissionShorten the timeMixer accessoriesStop timeMaximum diameter

The invention relates to a rapid locking mechanism for a stirring paddle. The rapid locking mechanism for the stirring paddle comprises a stirring shaft, the stirring paddle, a pressure sleeve, an adhesive tape retaining sleeve, adhesive tapes and two cams, wherein the stirring shaft is arranged in the stirring paddle; a drive pin arranged on the stirring shaft is located in a groove arranged on the stirring paddle; the pressure sleeve is sheathed onto the stirring shaft; the adhesive tape retaining sleeve is sheathed onto the pressure sleeve; the adhesive tapes are arranged between the pressure sleeve and the adhesive tape retaining sleeve; the upper ends and the lower ends of the adhesive tapes are respectively contacted with the top end of the adhesive tape retaining sleeve and the bottom end of the pressure sleeve; the two cams are respectively arranged at both sides of the stirring shaft through a cam pin shaft; and when in a locking state, the bottom end of the adhesive tape retaining sleeve is compressed tightly by the surface at the maximum diameter position of each cam; the adhesive tape retaining sleeve and the pressure sleeve are respectively supported by the upper ends and the lower ends of the adhesive tapes; and the upper end face of the stirring paddle is compressed tightly by the bottom end face of the pressure sleeve. According to the rapid locking mechanism for the stirring paddle, any parts do not need to be disassembled or assembled during the process of installing and disassembling the stirring paddle and the stirring shaft, thus, the stirring paddle and the stirring shaft are rapidly connected and are effectively locked; the stirring paddle replacement time and the stop time of equipment are shortened; and the utilization ratio of a machine is greatly increased.

Owner:LIUZHOU HUT CHEM MACHINERY

Advertising box

Owner:JIANGXI GUANGDI INTELLIGENT STEEL ART GRP CO LTD

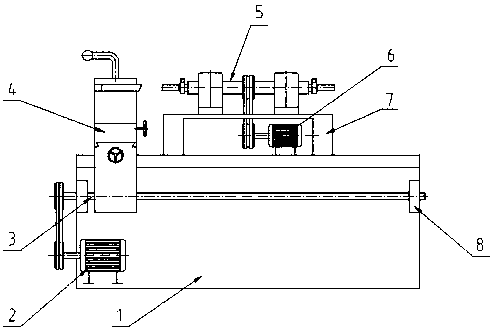

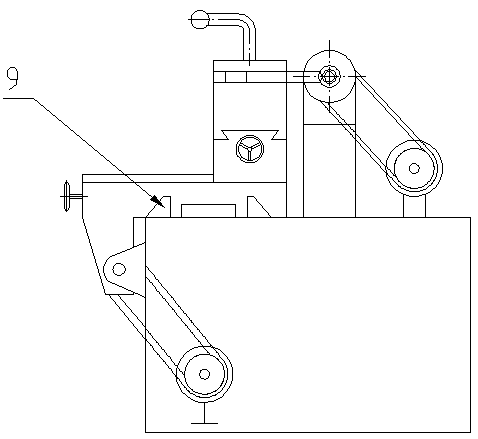

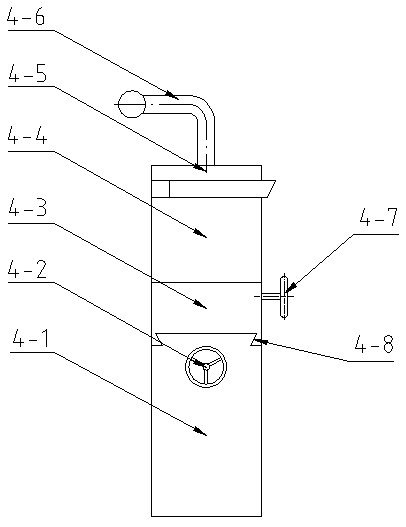

Ceramic membrane tube machining equipment

PendingCN109176276AHigh hardnessImprove wear resistanceRevolution surface grinding machinesGrinding drivesEngineeringDrive motor

The invention discloses special equipment for machining a ceramic membrane tube. The equipment comprises a lathe body, a travelling mechanism, a main shaft mechanism, a main shaft fixing seat, a driving motor, a main shaft motor, a lead screw and lead screw bearing blocks. A high-precision trapezoidal table guide rail is arranged on the lathe body, the travelling mechanism is arranged on the guiderail, a screw hole is formed in the lower portion of the travelling mechanism, the screw hole is matched with the lead screw, and the lead screw is fixed on the lead screw bearing blocks on the two sides of the lathe body; the main shaft mechanism is fixed on the main shaft fixing seat, the main shaft fixing seat is fixed on the lathe body, and the corresponding fixing mode is a bolt fixing modeor a welding mode; the lead screw and the driving motor are connected through a belt wheel and a belt, the main shaft mechanism and the main shaft motor are connected through a belt wheel and a belt,and the main shaft motor is fixed on the lathe body through bolts; and a lathe tool is arranged on the travelling mechanism. According to the equipment, the travelling mechanism is used for driving the lathe tool to run, so that the machining of the ceramic membrane tube is realized. The equipment has the advantages of being reasonable in structure and convenient to operate, one-time clamping of two ends for machining is realized, the machining precision and coaxiality of products are guaranteed, and the workload of workers is reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Rapid locking mechanism for stirring paddle

ActiveCN102814141BQuick installationQuick change actionMixer accessoriesLocking mechanismMaximum diameter

The invention relates to a rapid locking mechanism for a stirring paddle. The rapid locking mechanism for the stirring paddle comprises a stirring shaft, the stirring paddle, a pressure sleeve, an adhesive tape retaining sleeve, adhesive tapes and two cams, wherein the stirring shaft is arranged in the stirring paddle; a drive pin arranged on the stirring shaft is located in a groove arranged on the stirring paddle; the pressure sleeve is sheathed onto the stirring shaft; the adhesive tape retaining sleeve is sheathed onto the pressure sleeve; the adhesive tapes are arranged between the pressure sleeve and the adhesive tape retaining sleeve; the upper ends and the lower ends of the adhesive tapes are respectively contacted with the top end of the adhesive tape retaining sleeve and the bottom end of the pressure sleeve; the two cams are respectively arranged at both sides of the stirring shaft through a cam pin shaft; and when in a locking state, the bottom end of the adhesive tape retaining sleeve is compressed tightly by the surface at the maximum diameter position of each cam; the adhesive tape retaining sleeve and the pressure sleeve are respectively supported by the upper ends and the lower ends of the adhesive tapes; and the upper end face of the stirring paddle is compressed tightly by the bottom end face of the pressure sleeve. According to the rapid locking mechanism for the stirring paddle, any parts do not need to be disassembled or assembled during the process of installing and disassembling the stirring paddle and the stirring shaft, thus, the stirring paddle and the stirring shaft are rapidly connected and are effectively locked; the stirring paddle replacement time and the stop time of equipment are shortened; and the utilization ratio of a machine is greatly increased.

Owner:LIUZHOU HUT CHEM MACHINERY

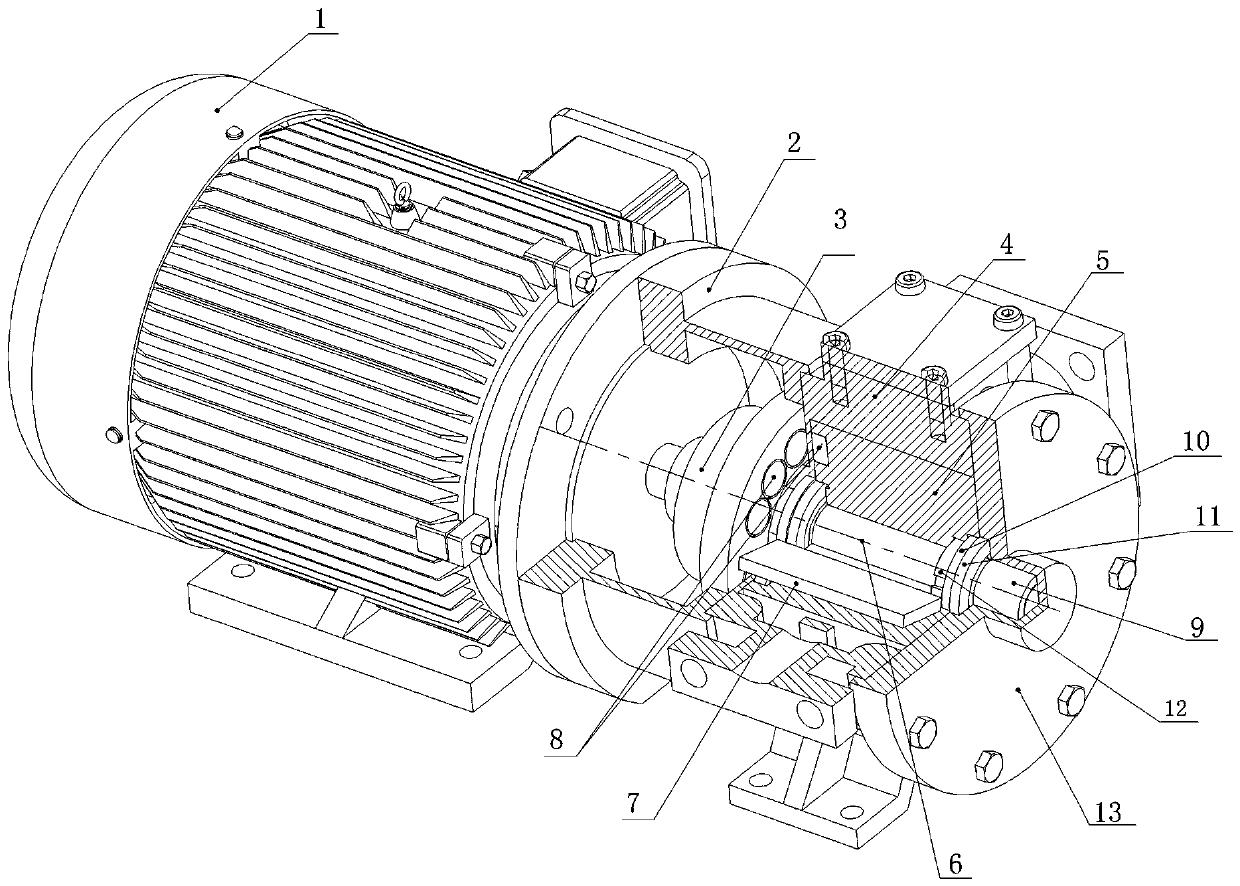

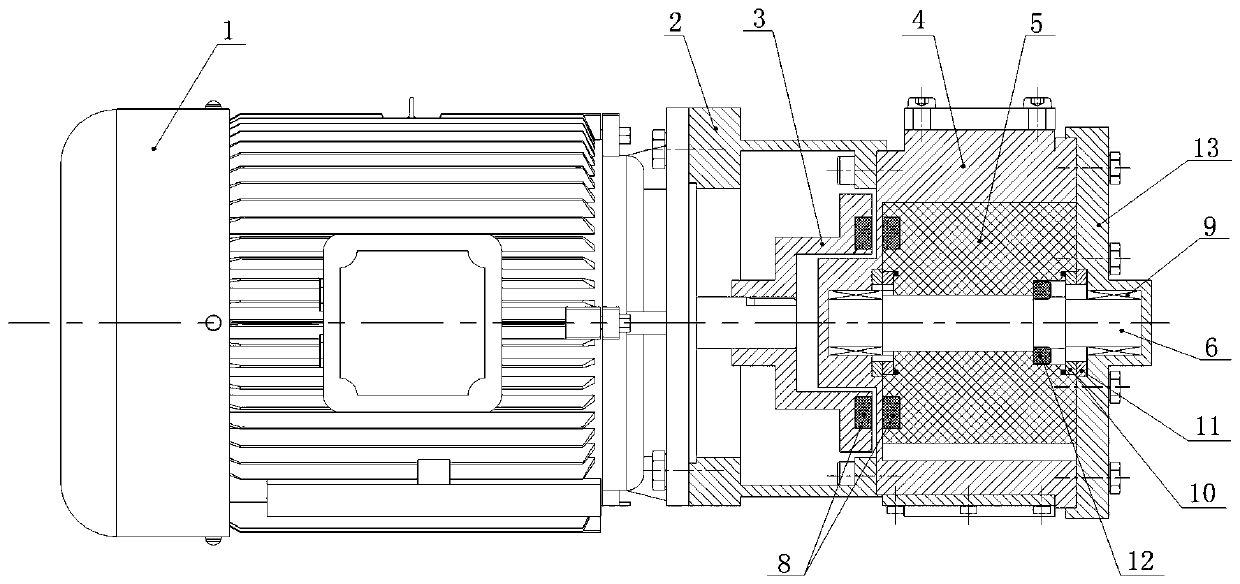

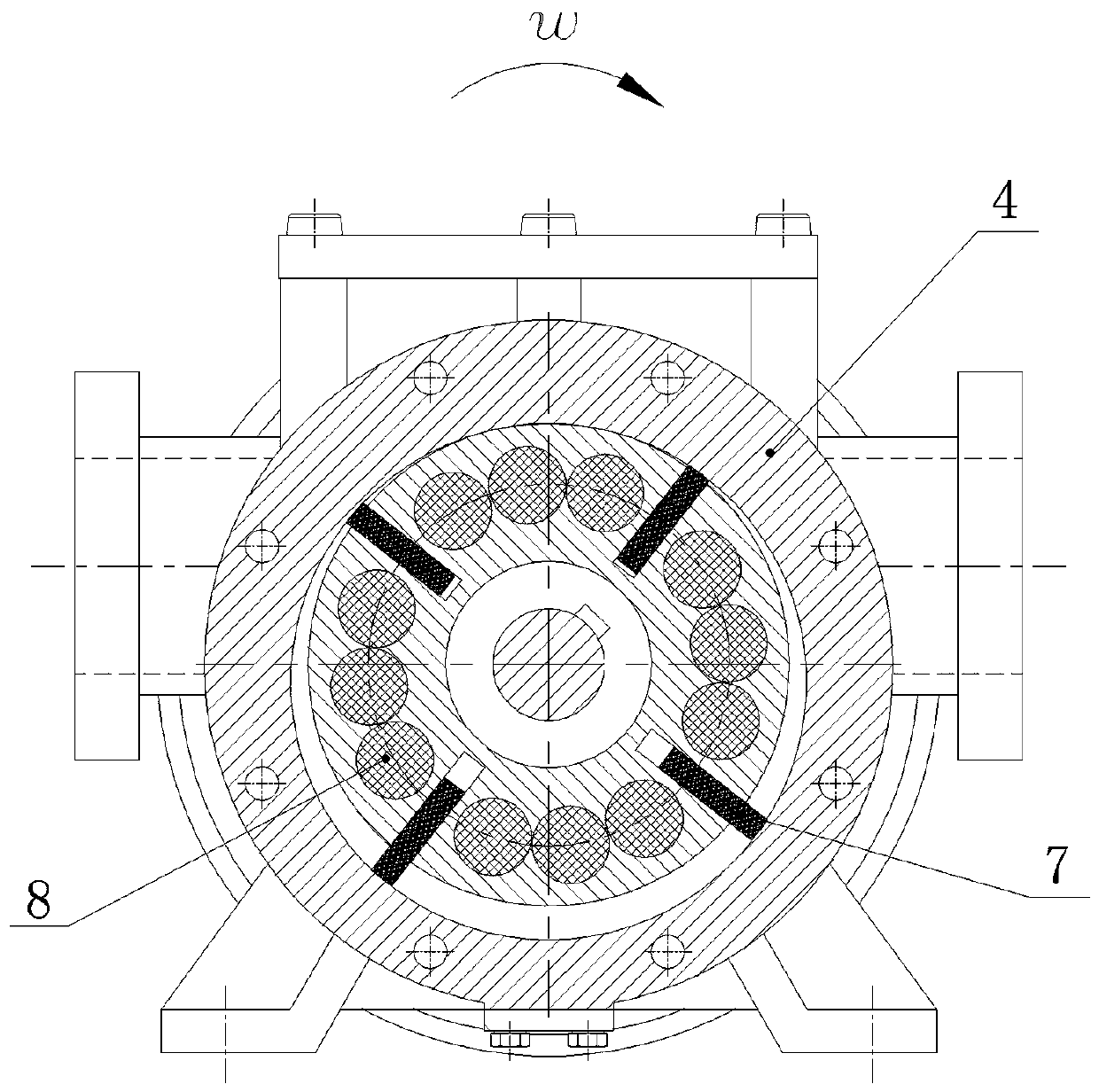

Disc Magnetic Connection Chemical Sliding Vane Pump

ActiveCN105179232BReduce wear rateImprove delivery efficiencyRotary piston pumpsRotary piston liquid enginesMagnetic tension forceRotor magnets

Disclosed is a disc-type magnetically connected chemical sliding vane pump, which is used for conveying various oils and chemical media. It includes motor, connection plate, disc-type external magnetic rotor, pump body with eccentric inner cavity, internal magnetic rotor with groove, pump shaft, sliding plate, circular magnet, sliding bearing, hard alloy moving ring, silicon carbide static ring, Round nut, pump back cover. The inner magnetic rotor of the present invention is integrated with the slotted rotor of the sliding vane pump to become an inner magnetic rotor with slots. Due to the change of the magnet installation method embedded in the outer magnetic rotor and the inner magnetic rotor with slots, the ring magnetic connection structure is changed to The disc-type magnetic connection structure directly uses the thin wall on the side of the pump body to isolate the outer magnetic rotor and the inner magnetic rotor with grooves, which cancels the isolation sleeve necessary for the previous ring-type magnetic pump, shortens the length of the pump body, and makes the structure simpler and more compact. The maintenance efficiency is greatly improved, the skill requirements for maintenance personnel are reduced, and the high efficiency and energy saving of the pump are realized.

Owner:BOTOU CITY GUANG TENG MACHINERY MFG

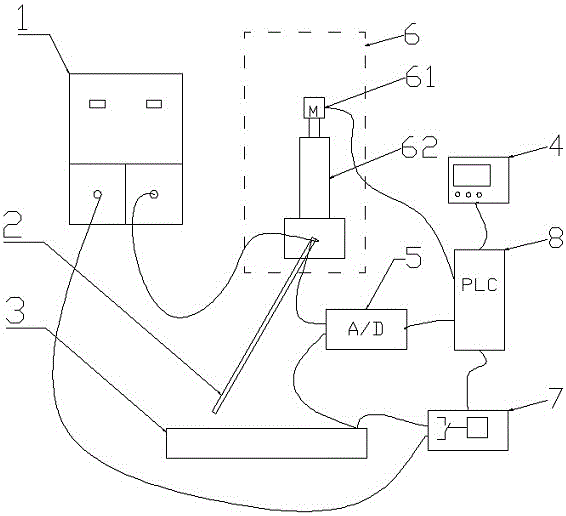

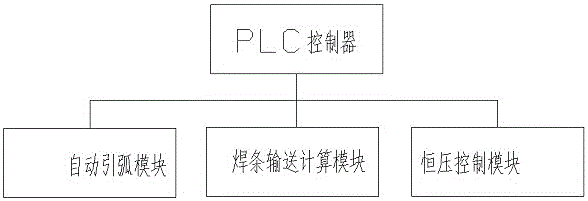

A kind of welding rod automatic welding system and automatic welding method

ActiveCN105345226BRealize automatic weldingGuaranteed uptimeArc welding apparatusPower flowWelding power supply

The invention discloses an automatic welding system for a welding rod and an automatic welding method. The automatic welding system comprises a welding power source, the welding rod and a work piece, and also comprises a human-computer interaction interface, an electric arc information acquisition system, a motion executing mechanism and a welding power source control module, wherein the human-computer interaction interface is used for setting parameters and displaying data; the electric arc information acquisition system is used for acquiring the data of welding voltage and welding current between the welding rod and the work piece in real time; the motion executing mechanism is used for driving the welding rod to move according to the information acquired by the electric arc information acquisition system and regulating the speed in real time according to a specific control strategy so as to regulate the voltage of the electric arc; the welding power source control module is used for connecting or disconnecting the welding power source according to the information acquired in real time by the electric arc information acquisition system. The automatic welding system disclosed by the invention is simple to clamp; periodic regulation is not needed; the processing is reasonable; the voltage fluctuation range of the electric arc is small during welding; automatic arc striking can be realized; the inclination angle of the welding rod can be regulated; the conveying speed of the welding rod can be automatically regulated; power is automatically cut off after welding is ended.

Owner:威海大威海洋机器人有限公司

Refractory material product machining clamp and machining method based on refractory material product machining clamp

The invention discloses a refractory material product machining clamp and a machining method based on the refractory material product machining clamp. The refractory material product machining clamp comprises a chuck, the bottom end face of the chuck is a base, the top end face of the chuck is a clamping face, the base of the chuck is fixedly connected with a clamping block, the clamping block is connected with a connecting rod, and the connecting rod penetrates through a central inner cavity of the chuck. The connecting rod is further sleeved with a plug. When the workblank is arranged on the connecting rod in a sleeving mode, one end of the workblank abuts against the clamping face of the chuck, and the other end of the workblank abuts against the plug. The shape machining of a product is completed through one-time clamping, the coaxiality of the workblank is determined by the chuck, the plug and the connecting rod at the same time, and therefore the coaxiality consistency of the inner cylindrical face and the outer cylindrical face of the product is good, the outer diameter consistency of the upper end and the lower end is good, the positioning precision is high, the machining precision is high, and the use requirement of the product is met.

Owner:IRICO

Oil retainer structure of novel three-phase asynchronous motor

InactiveCN102818029ADo not change the assembly methodDo not change usage requirementsEngine sealsThree phase asynchronous motorSmall hole

The invention relates to an oil retainer structure of a novel three-phase asynchronous motor, wherein the oil retainer structure of the novel three-phase asynchronous motor comprises an oil retainer body; small holes are arranged on the oil retainer body at equal intervals; and the center of the oil retainer body is provided with an oil retainer central hole which is internally provided with a thread. The oil retainer structure of the novel three-phase asynchronous motor provided by the invention is compact and reasonable in structure; the oil retainer structure is connected with a shaft and is not required to be heated; the oil retainer structure of the novel three-phase asynchronous motor is simple to process, convenient to operate, short in cycle, low in cost and high in operating efficiency, and does not change the original assembling method and using requirements of a motor.

Owner:WUXI ZHONGDA MOTORS

Cold heading machine manipulator frame fixing seat

InactiveCN107377849AGood transmission effectEasy to install and maintainForging/hammering/pressing machinesGear wheelDrive shaft

A fixed seat for a manipulator frame of a cold heading machine, characterized in that: the fixed seat for the manipulator frame of a cold heading machine includes a fixed card seat, a guide rod, a transmission shaft, a pressure plate, a bottom plate, and an inner hexagonal screw; wherein: it includes a fixing device and a transmission device, the fixing device is composed of fixed decks on both sides, guide rods, pressure plates and bottom plates, both sides of the guide rods are installed and connected with the fixed decks by hexagon socket screws, a base plate is provided under the guide rods, and a pressure plate is provided above the guide rods. A transmission shaft is also erected on the fixed deck, and a manipulator transmission lever or a transmission gear can be externally connected to both sides of the transmission shaft, and the device has a symmetrical structure. The advantages of the present invention: the fixed seat of the manipulator frame of the cold heading machine described in the present invention has a simple structure and a reasonable world, improves the transmission performance of the existing domestic cold heading machine, and has the advantages of simple processing, convenient installation and maintenance, and reasonable structure.

Owner:陈小慧

Processing method of beverage made from hemsley rockvine and pumpkin

InactiveCN108522906ASweet tasteTaste fitSugar food ingredientsFood homogenisationRhizomeFood processing

The invention relates to the technical field of food processing, in particular to a processing method of a beverage made from hemsley rockvine and pumpkin. The processing method comprises the following nine processing technologies: hemsley rockvine harvesting, rhizome cleaning, hemsley rockvine leaf juicing, rhizome juicing, supernatant mixing, pumpkin juice preparation, enzymolysis, homogenization, and constant-volume sterilization. The physical processing method is adopted, and the method is reasonable in processing and simple to operate, organically combines the medicinal value of hemsley rockvine with the edible value of pumpkin, and produces the unique health-care beverage made from the hemsley rockvine. The beverage is green and healthy, has shelf life of 22-24 months, is convenientto carry, can be drunk after being opened, and is convenient and fast. The main component in the beverage is pumpkin, so that more working people or pumpkin eating lovers can enjoy the pumpkin beverage anytime and anywhere. Long-term consumption of the beverage has the effects of enhancing immunity and inhibiting depression.

Owner:贵州坤健源生态农业发展有限公司

Oil storage device of high-pressure motor bearing

InactiveCN101710749BEasy to processReasonable processingSupports/enclosures/casingsEngine lubricationCentrifugal forceHigh pressure

The invention relates to an oil storage device of a high-pressure motor bearing, which is mainly used for improving the protection grade of the high-pressure motor bearing, such as the functions of dust prevention and water prevention. An oil throwing disk is fixed on a rotating shaft of a motor, a V-shaped ring is put in the outer end of an inner ring of a left cover of the bearing to improve the protection grade, and the inner side of a bearing set is fixed through a right cover of the bearing. The oil storage device is characterized in that labyrinth parts are arranged on an inner cover and an outer cover of the bearing, and the left cover of the bearing is internally and additionally provided with the inner ring. The oil storage device has simple, compact and reasonable structure and obvious effect. Under the condition of not changing structure materials, the protection grade of the motor is effectively improved through additionally arranging a labyrinth ring and the labyrinth parts on the inner cover and the outer cover of the bearing and the oil throwing disk. The inner ring is additionally arranged in the left cover of the bearing, and lubricating oil is thrown into an oil storage cavity in the inner ring and the bearing due to the action of centrifugal force, thus the oil storage capacity is greatly enhanced. For part processing, the oil storage device is simple and reasonable and has no influence on mechanical property of workpieces, and for mechanical deviation, because a single radial edge is preserved with an allowance of 1mm and a single axial edge is preserved with an allowance of 2mm, the assembly of the parts have no problems.

Owner:SEC ELECTRIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com