A kind of welding rod automatic welding system and automatic welding method

An automatic welding and welding rod technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve stable operation, simple equipment, and meet the requirements of welding rod process experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

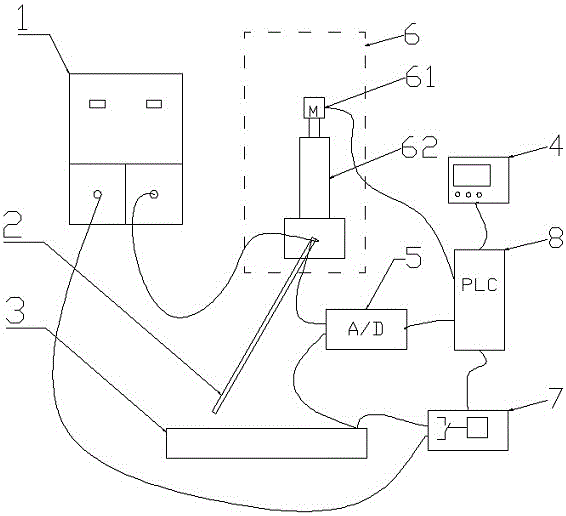

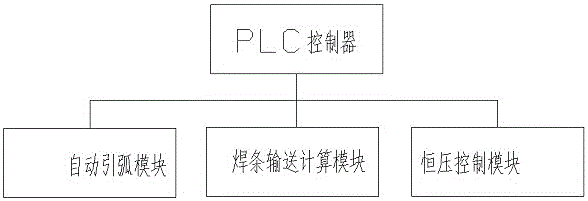

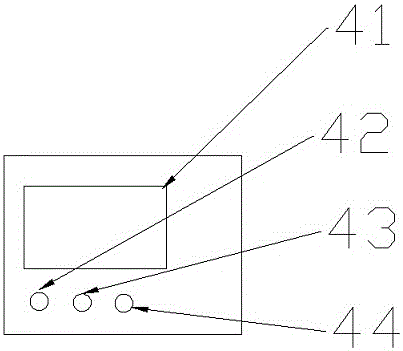

[0034] Such as figure 1 As shown, an automatic electrode welding system includes a welding power source 1, an electrode 2, a workpiece 3, and a human-computer interface 4 for setting parameters, displaying data, and setting the initial feeding speed V 1 , average arc voltage U s , welding rod 2 inclination angle α and welding rod 2 effective burning length L; display real-time feeding speed V, real-time arc voltage U, arc burning state and average voltage and other information, and control the start and stop of the welding process; arc information acquisition system 5, with To collect the welding voltage and welding current data between the electrode 2 and the workpiece 3 in real time, and convert the actual welding current and welding voltage into a 0-10V signal according to the corresponding ratio for control; the motion actuator 6, According to the infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com