A pressing hand assembly for a horizontal jack

A technology of pressing hands and jins, which is applied to the field of pressing hand components for horizontal jacks, can solve the problems of low efficiency, troublesome operation, labor and time consuming, etc., and achieves the effects of simple processing, simple structure and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

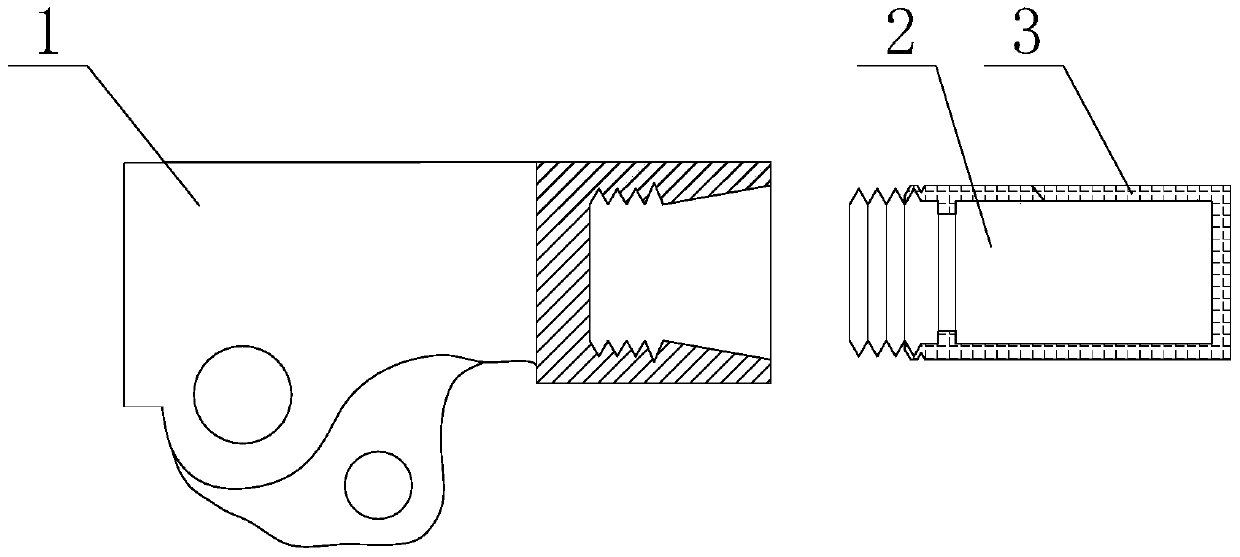

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a pressing hand assembly for a horizontal jack proposed by the present invention.

[0017] refer to figure 1 , a pressing hand assembly for a horizontal jack proposed by the present invention, comprising: pressing hand body 1, handle 2, handle cover 3;

[0018] The snap handle body 1 includes a mounting part and a handle connecting part connected to each other. The end of the mounting part away from the handle connecting part is connected to the jack. There is a columnar cavity extending from the end away from the mounting part to the middle in the handle connecting part. One end of the installation part is open, and the columnar cavity is composed of a first chamber and a second chamber connected in sequence, the first chamber is located on the side away from the opening of the second chamber, the inner wall of the first chamber is provided with internal threads, and the second chamber is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com