Novel electric discharge machining machine tool for heavy-duty tire mold

A technology for electric discharge machine tools and heavy tires, which is applied in the direction of manufacturing tools, electric processing equipment, metal processing equipment, etc., can solve the problems of unrepairable error rate, inconvenient clamping of workpieces, and falling off of workpieces, so as to achieve reasonable processing and improve processing Accuracy and precision maintenance life, the effect of adjustable head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with specific embodiment the present invention is described in further detail:

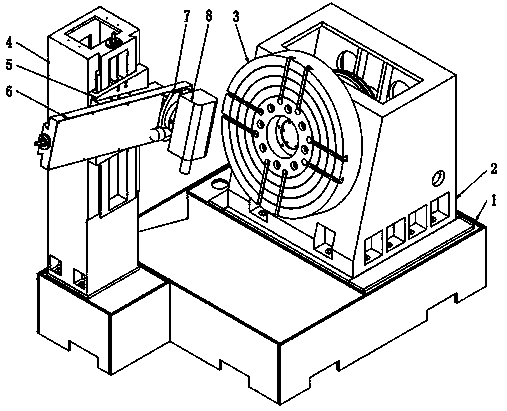

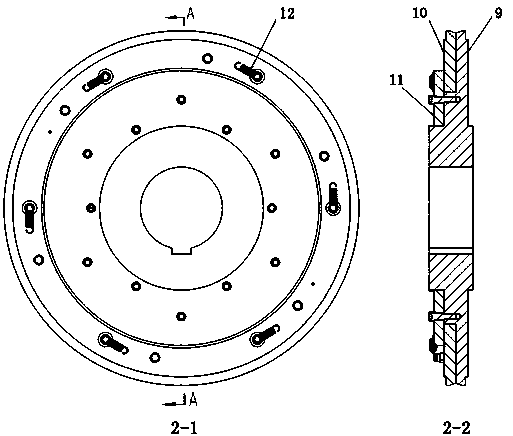

[0012] Such as figure 1 , 2 As shown, a new type of electric discharge machine tool for heavy-duty tire molds includes a base 1, and the base 1 is provided with a rotary box 2. The main shaft in the rotary box 2 is connected to the four-jaw chuck 3, and the rotary box 2 is connected to The surface contacted by the four-jaw chuck 3 is inclined at 15°; the base 1 is provided with a column 4, and the column 4 is provided with an inclined slide plate 5 that can move up and down along the guide rail surface, and the inclined slide plate 5 and the column 4 form a 15° included angle, the inclined slide plate 5 is provided with a crossbeam 6 at an angle of 15° with the column 4, the crossbeam 6 can move vertically with the four-jaw chuck 3, and the front end of the crossbeam 6 is provided with an indexing turntable 7. A discharge machine head 8 is arranged on the indexing tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com