Animal bone calcium micro-nano powder and preparation method thereof

A kind of animal bone, micro-nano technology, applied in the direction of food science, food preparation, drug combination, etc., can solve the problems of uncommon, lactose intolerance, etc., achieve the effect of reducing crushing stress, reducing energy consumption, advanced and reliable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

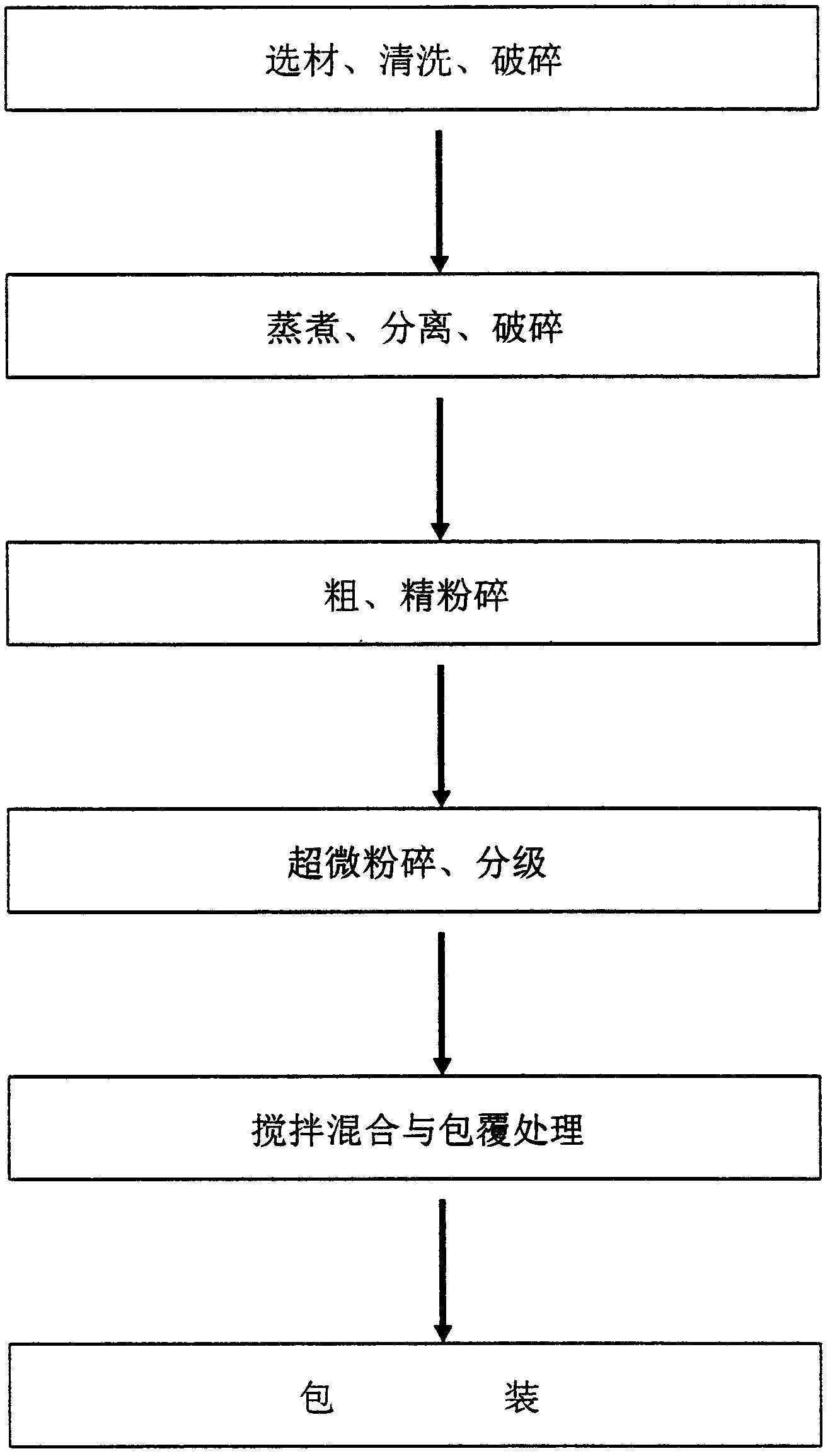

Image

Examples

Embodiment

[0026] 1. Select 100kg of fresh bovine hard bones, wash them, and crush them into 10-30mm bone pieces with a jaw crusher.

[0027] 2. Put the bone into the autoclave, add water and cook for 1.5-2 H , temperature control 127 ~ 143 ℃.

[0028] 3. After cooling, remove the broth, attach flesh and other organic matter, and obtain pure calcium salt bone blocks.

[0029] 4. Coarse and fine crushing: coarse powder to 100 mesh with a hammer mill;

[0030] A 47um powder was obtained with an impact mill.

[0031] 5. Superfine pulverization and grading: Pulverize in a high-speed airflow pulverizer, grading synchronously to obtain powders of 10-1000nm, and re-grind powders exceeding 1um.

[0032] 6. Add this powder and α-starch into the mixer at the same time, the starch particle size is 47um, and the stirring speed is 800-1500γ.min -1 , The weight ratio of starch to powder is 5-8:1.

[0033] 7. Put the mixture into the dry-type mechanical impact machine, the child particles are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com