Electrode bar for removing burrs through electrolyzing

An electrode rod and deburring technology, which is applied in the field of machining, can solve the problems that the electrode sheet is not covered in place, cannot meet the quality requirements, and the design of the electrode sheet is complicated, etc., so as to save working time, fast burr removal speed, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

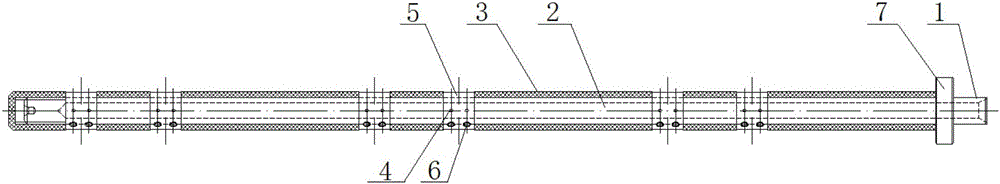

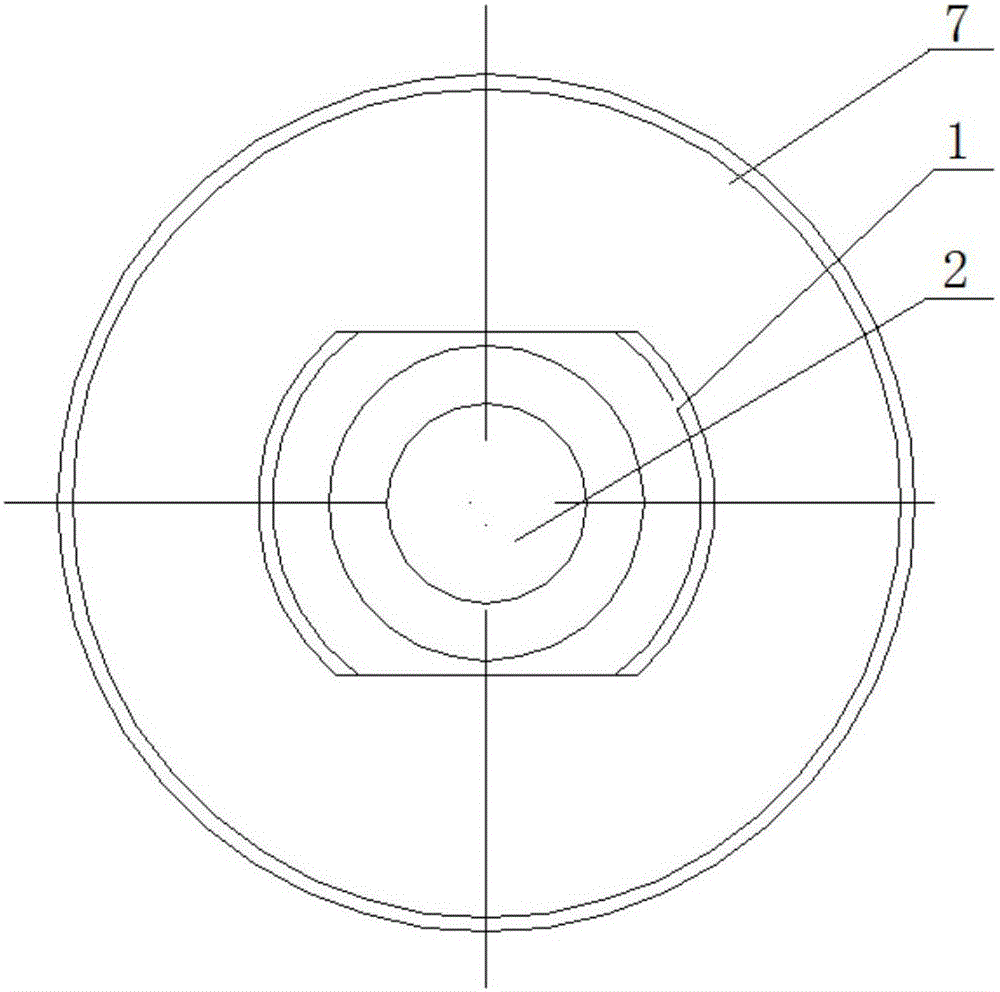

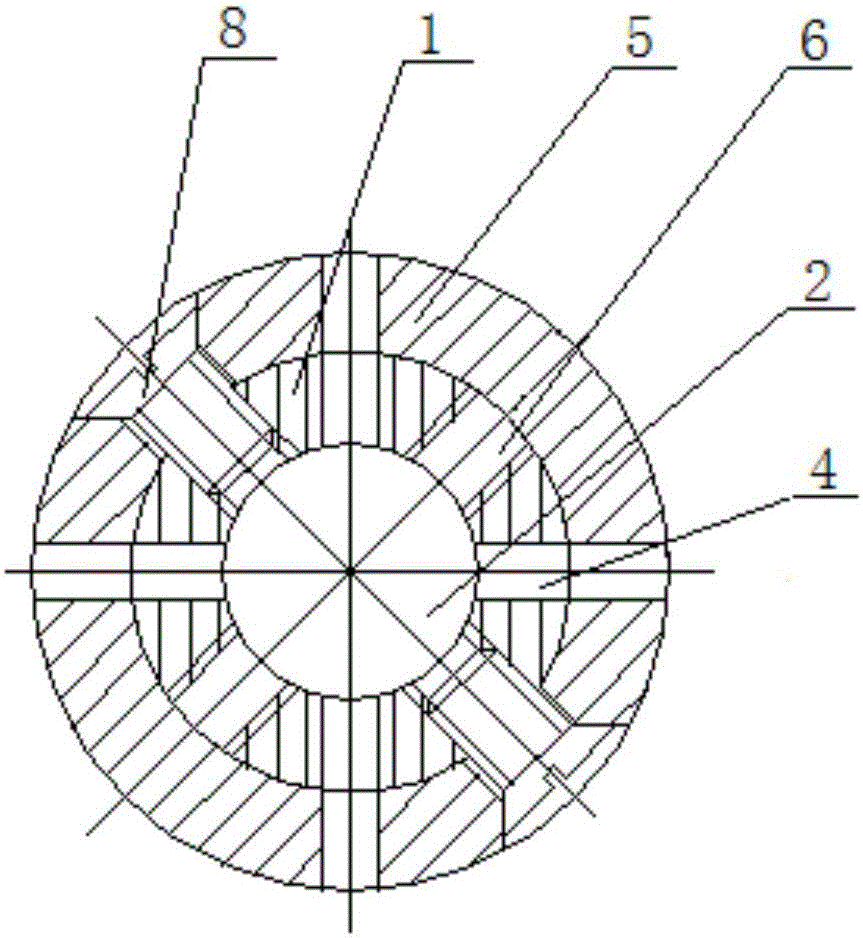

[0019] The specific embodiment of the present invention is like this: with reference to Figure 1-4 As shown, an electrode rod for electrolytic deburring includes a cylindrical electrode rod body 1, an electrolyte cavity 2 is provided inside the electrode rod body 1, and one end of the electrode rod body 1 is sealed so that the electrolyte solution is in the electrolyte cavity. A certain pressure is formed in the body 2; the electrode rod body 1 is provided with at least one section of the electrolysis part that can spray out the electrolyte, and at least one circle of electrolysis units arranged along its rotation direction is provided on the section of the electrolysis p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com