Cold heading machine manipulator frame fixing seat

A fixed seat and cold heading machine technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the inconvenience of product test run debugging, poor stability of fixing devices, high processing technology requirements, etc. problems, to achieve the effect of simple structure, simple processing, and improved transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

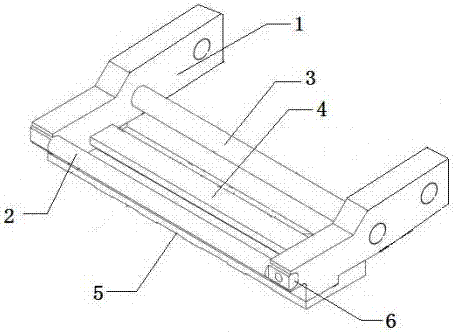

[0012] This embodiment provides a fixed seat for a manipulator frame of a cold heading machine, which is characterized in that: the manipulator frame fixed seat for a cold heading machine includes a fixed card seat (1), a guide rod (2), a transmission shaft (3), a pressing plate (4), bottom plate (5), hexagon socket head screw (6);

[0013] Among them: including the fixing device and the transmission device, the fixing device is composed of the fixing bracket (1), the guide rod (2), the pressure plate (4) and the bottom plate (5) on both sides, and the two sides of the guide rod (2) pass through the inner The hexagonal screw (6) is installed and connected with the fixed deck (1), the bottom plate (5) is arranged under the guide rod (2), the pressure plate (5) is arranged above, and the transmission shaft ( 3).

[0014] Both sides of the transmission shaft (3) can be externally connected with manipulator transmission levers, and the device has a symmetrical structure.

Embodiment 2

[0016] A fixed seat for a manipulator frame of a cold heading machine, characterized in that: the fixed seat for the manipulator frame of a cold heading machine includes a fixed card seat (1), a guide rod (2), a transmission shaft (3), a pressing plate (4), and a bottom plate (5), hexagon socket head screw (6);

[0017] Among them: including the fixing device and the transmission device, the fixing device is composed of the fixing bracket (1), the guide rod (2), the pressure plate (4) and the bottom plate (5) on both sides, and the two sides of the guide rod (2) pass through the inner The hexagonal screw (6) is installed and connected with the fixed deck (1), the bottom plate (5) is arranged under the guide rod (2), the pressure plate (5) is arranged above, and the transmission shaft ( 3).

[0018] Both sides of the transmission shaft (3) can be externally connected with mechanical transmission gears, and the device has a symmetrical structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com