Method for measuring cone angle of cone mirror

A measuring method and technology of cone lens, applied in the field of optical measurement, to achieve the effect of less experimental instruments, convenient operation and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

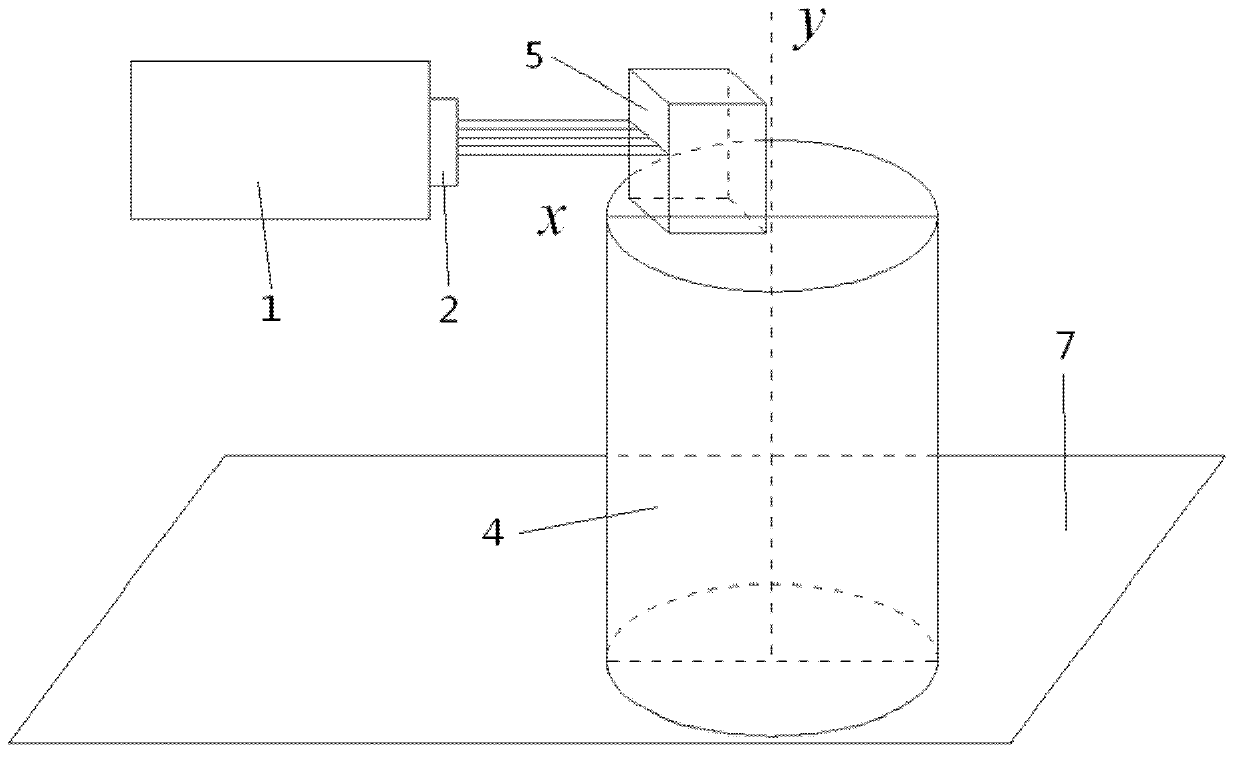

[0045] Embodiment 1: utilize measuring device to realize the high-precision measurement of cone angle, to a measured axicon 3 is the concrete measurement of the cone angle of measured conical mirror and the adjustment steps are described as follows:

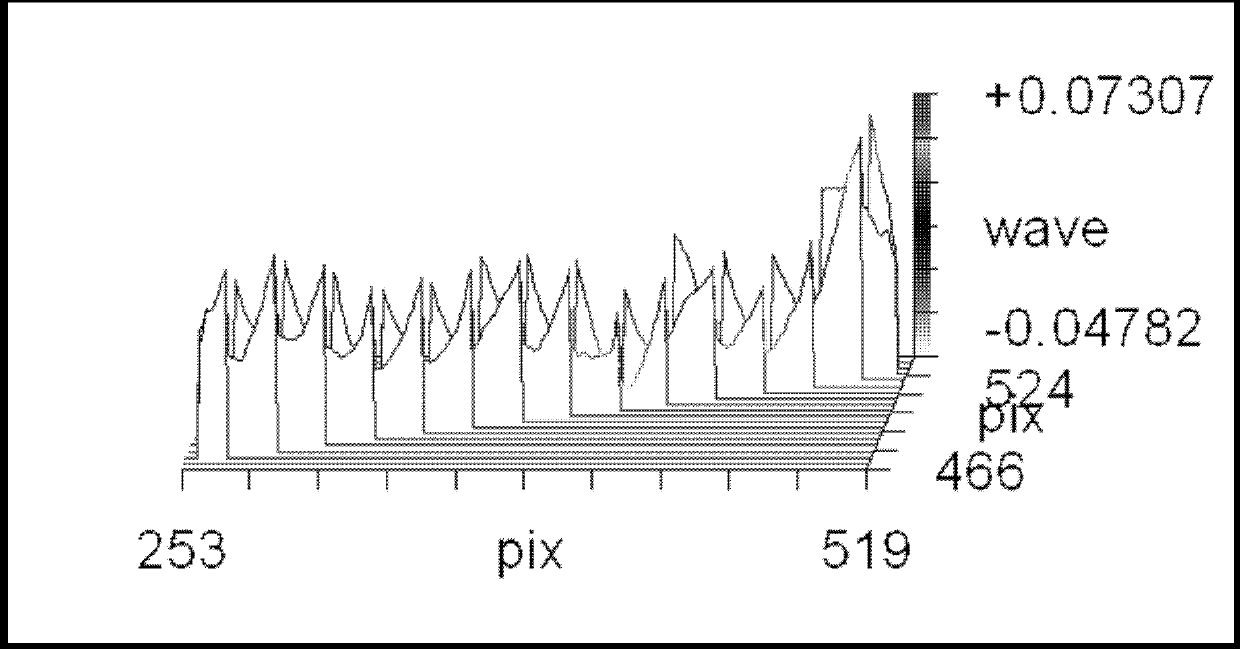

[0046] 1) Install the plane lens 2 on the interferometer 1, fine-tune the inclination and pitch of the interferometer 1, so that the parallel light emitted by the plane lens 2 is a standard parallel light; fix the cube 5 on the plane of the rotating platform 4, Rotate the rotating platform 4 so that the reflected light from one of the surfaces of the cube 5 can enter the interferometer 1, and the reflected light and the reference light in the interferometer 1 form interference fringes, such as figure 1 As shown; the tilt and pitch of the rotating platform 4 and the horizontal direction of the optical platform are fine-tuned, and the rotating platform 4 is also slightly rotated to adjust the interference fringes in the interferomet...

Embodiment 2

[0051] Embodiment 2: utilize measuring device to realize the high-precision measurement of cone angle, provide the embodiment that measured axicon 3 is the measured triangular axicon, specific description: step 1-4 is identical with embodiment 1, and difference is: with Conical mirrors are different. The area used for self-collimation reflection of triangular aconic mirrors is a plane. Therefore, in steps 2 and 3, it is necessary to adjust the conical surface of the triangular aconic mirror to be perpendicular to the optical axis of parallel light, and use the self-collimating reflection of the conical surface The light forms zero interference fringes with the reference beam inside the interferometer 1. Since the area of the cone surface is relatively large, the shape of the formed interference fringes is easier to distinguish. The zero interference fringes formed will be in Figure 3C The interference fringe distribution map in shows zero fringes, in Figure 3A The root m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com