Multicore optical fiber connector

A multi-core optical fiber and connector technology, which is applied in the coupling of optical waveguides, can solve problems such as poor butt joint accuracy of ferrules, affecting data transmission performance, and insertion loss of ceramic ferrules, so as to improve data transmission performance and ensure Connection performance, effect of good connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

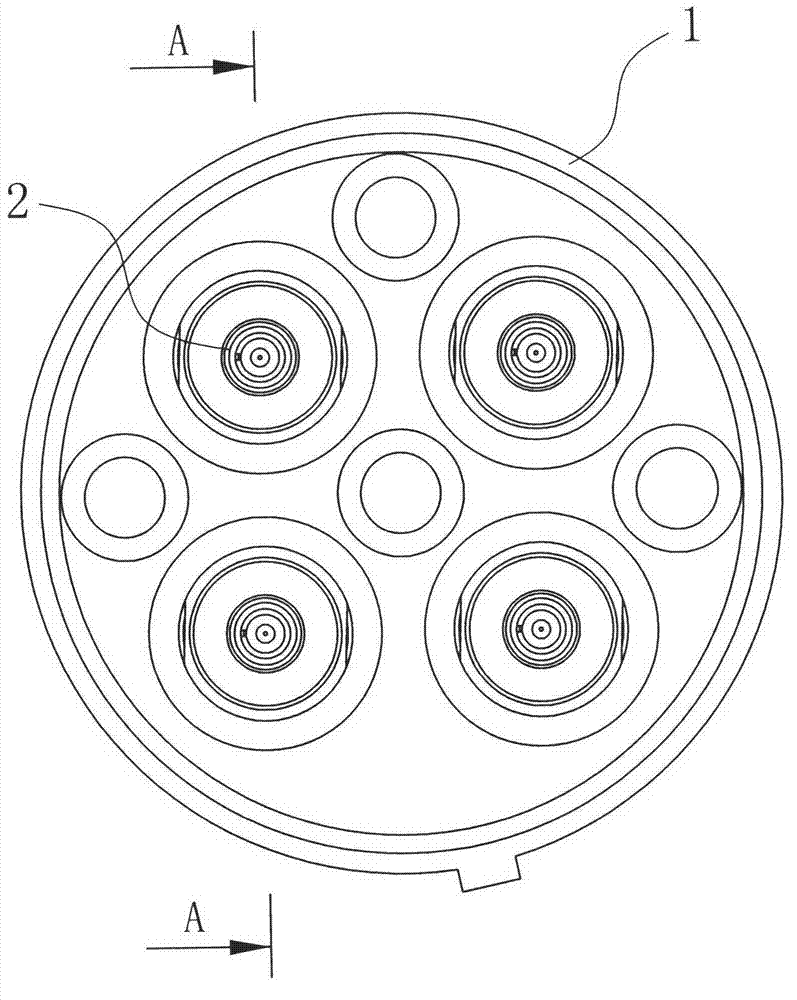

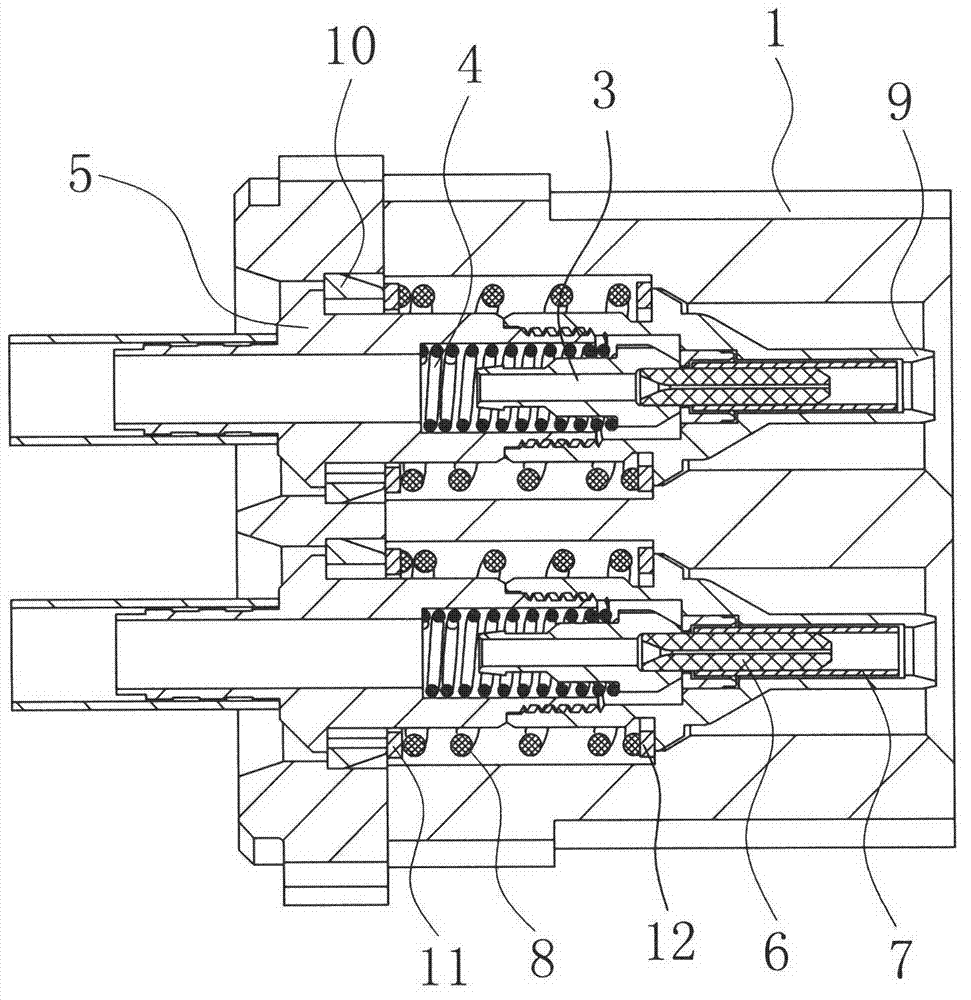

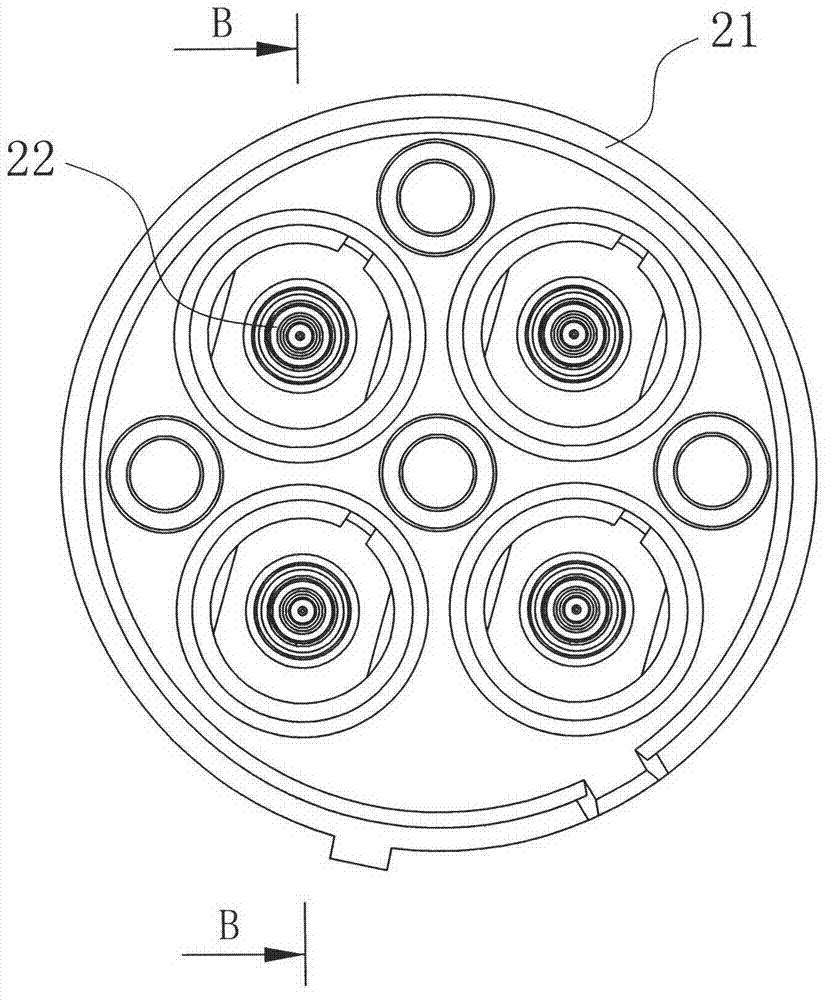

[0025] Embodiment one: see Figure 1~5 As shown, a multi-core optical fiber connector includes a plug assembly 14 and a receptacle assembly 29. The plug assembly 14 is composed of an insulating casing 1 and four plug ferrule assemblies 2 arranged in the insulating casing 1. Each The plug ferrule assembly 2 includes a ceramic ferrule seat 3, a spring 4 sleeved on the rear end of the ceramic ferrule seat 3, a spring stopper 5 that is offset against the tail end of the spring 4, and a ceramic ferrule set at the front end of the ceramic ferrule seat 3. The core 6 is set on the ceramic sleeve 7 outside the ceramic ferrule 6; in the plug assembly 14, there is a floating space between each of the plug ferrule assemblies 2 and the insulating case 1, and the In the floating space, the plug ferrule assembly 2 is covered with an outer spring 8, the outer edge wall of the spring stopper 5 is provided with external threads, and the front end of the plug ferrule assembly 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com