Manufacturing method of winding needle, manufacturing method of lithium ion battery and lithium ion battery

A lithium-ion battery and manufacturing method technology, applied in secondary batteries, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as affecting battery usage, digital product damage, and damage to the multi-layer structure of a battery core winding body. , to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

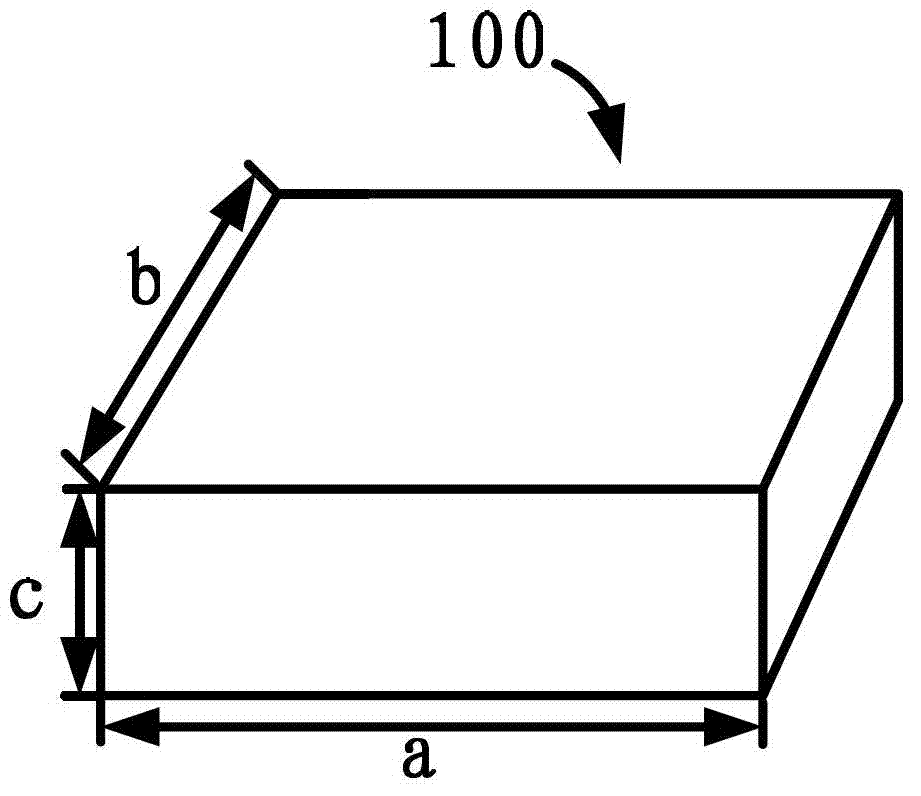

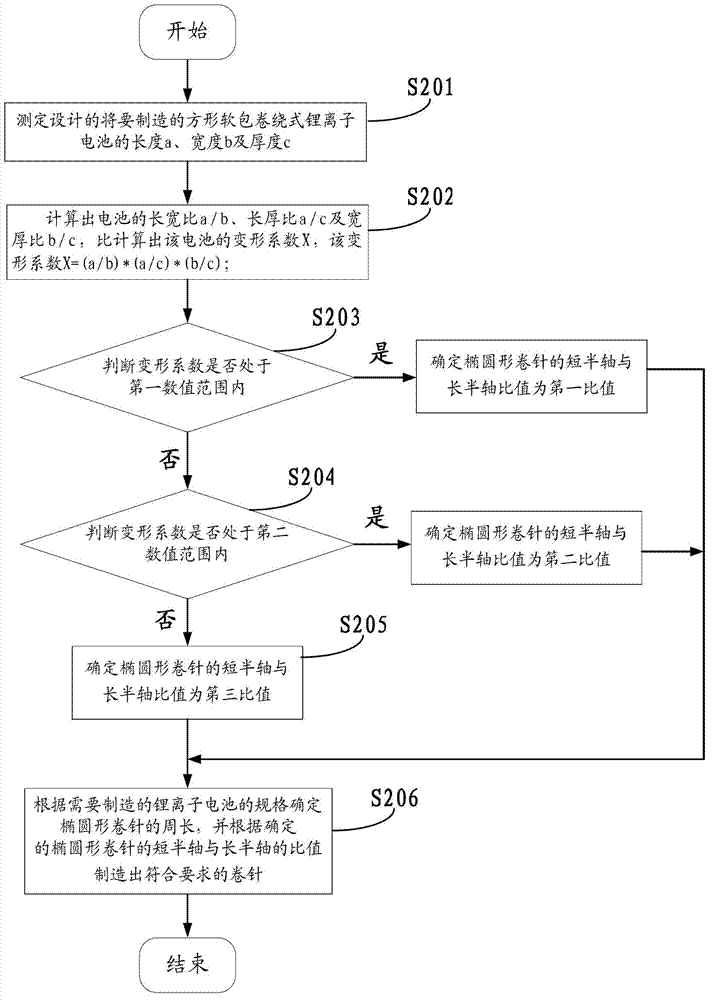

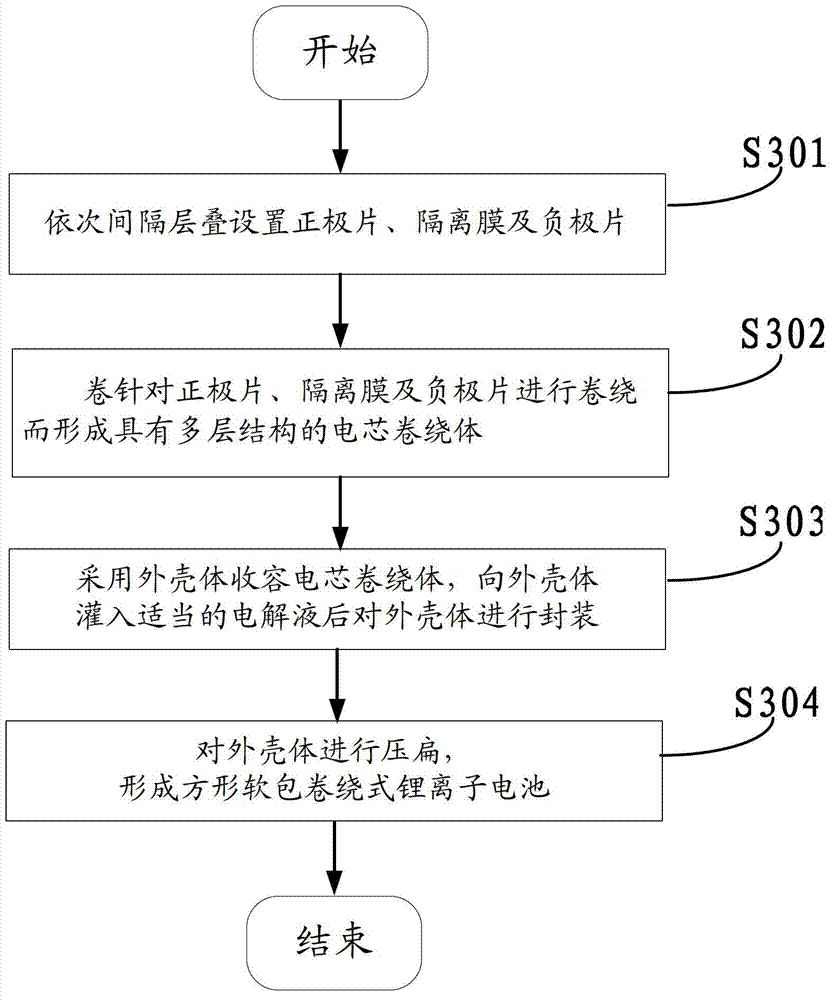

[0037] Such as figure 2 Shown, is the flow chart of the manufacturing method of rolling pin of the present invention, and this rolling pin is used for rolling square soft package winding type lithium-ion battery (such as figure 1 shown) 100. The manufacturing method of this roll needle comprises the steps:

[0038] S201: Measuring the length a, width b, and thickness c of the designed square soft-pack wound lithium-ion battery 100 to be manufactured;

[0039] S202: Calculate the aspect ratio a / b, aspect ratio a / c, and aspect ratio b / c of the lithium-ion battery 100, and calculate the deformation coefficient X of the lithium-ion battery 100, wherein the deformation coefficient X= (a / b)*(a / c)*(b / c);

[0040] S203: Determine the minor axis and the major axis of the elliptical rolling pin according to the calculated deformation coefficient X, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com