Leakage cable clamp

A leaky cable and fixture technology, applied in cable installation, cable installation in tunnels, electrical components, etc., can solve the problems of signal interference, inconvenient work, poor firmness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

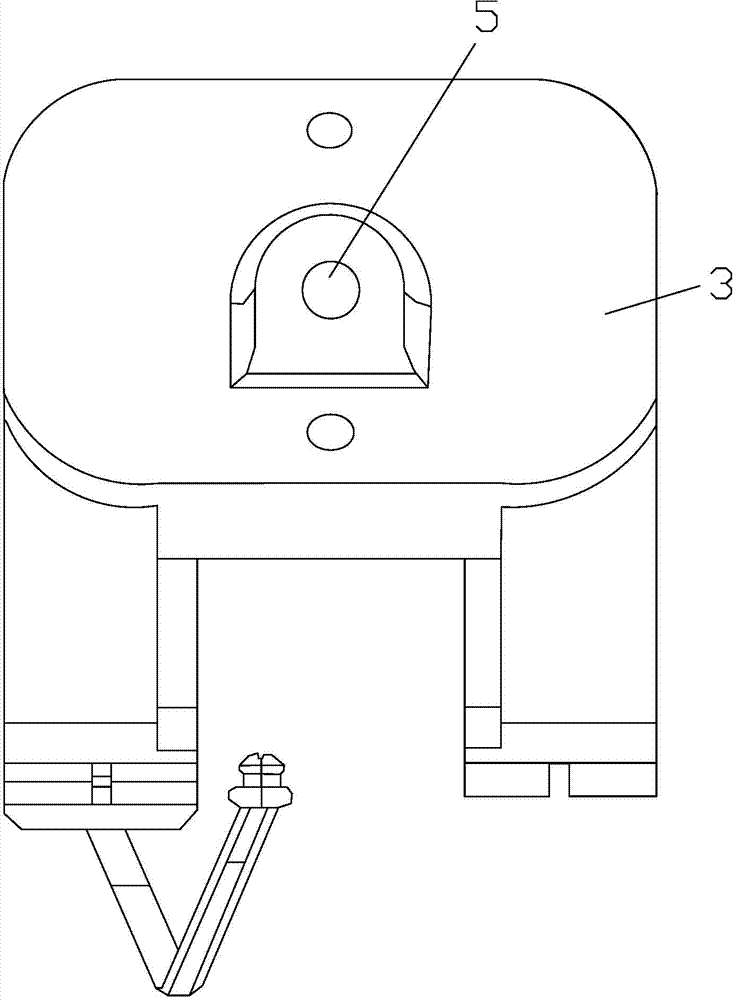

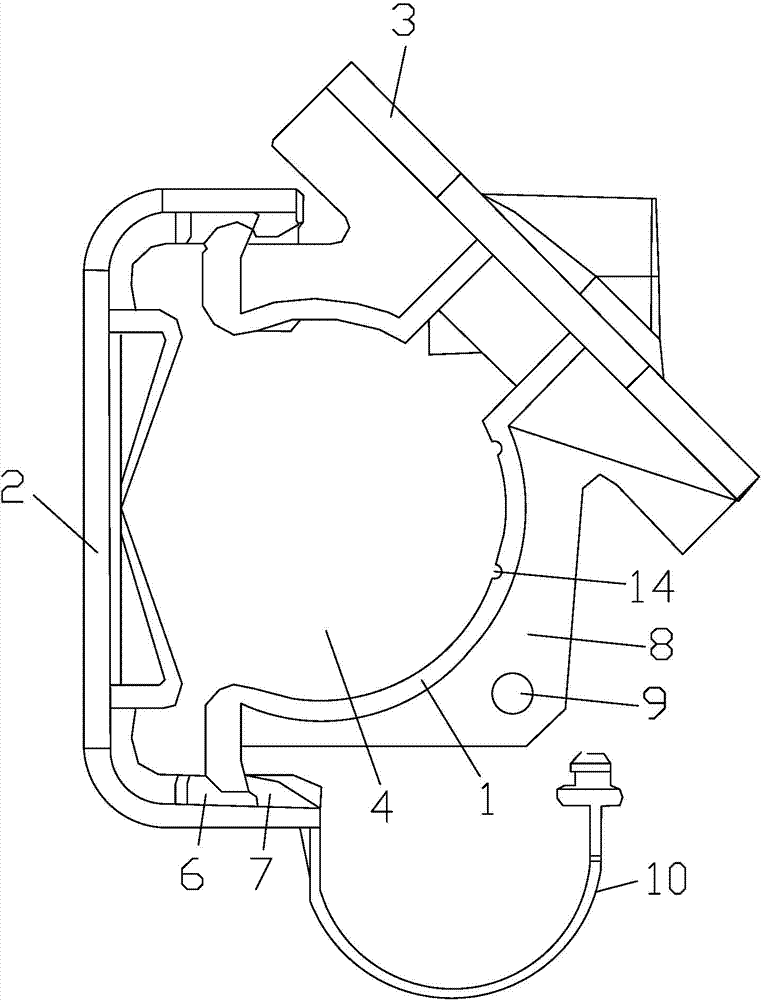

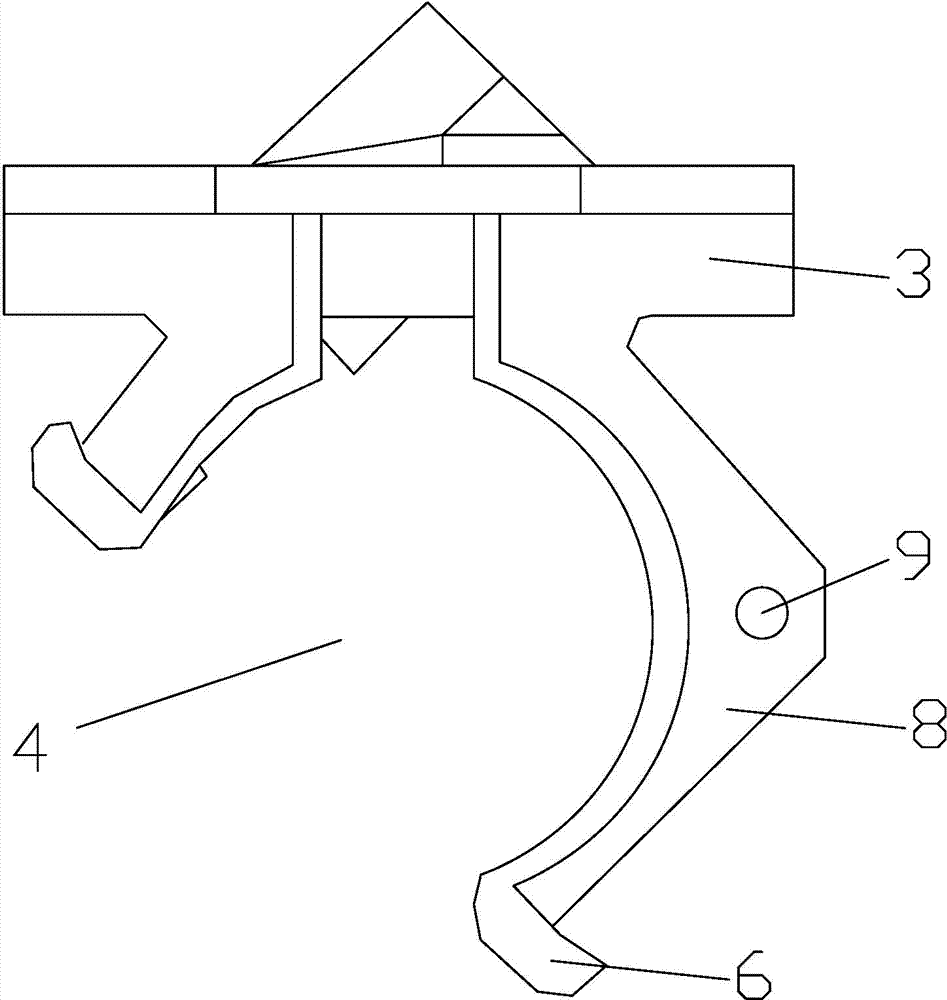

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] The leaky cable clamp according to the present invention includes: a support arm G-shaped seat 1 with a bottom plate and an inclined block 3 integrally constructed, the support arm G-shaped seat 1 forms a recess 4 for accommodating the leaky cable; and a cover 2 The cover body 2 and the arm-type G-shaped seat 1 can be fixedly connected by respective wedge-shaped blocks 6, 7; the cover body 2 is formed with a compressed leaky cable plate 15, which is installed in the leaky cable clamp In the state, the compressed leaky cable plate 15 is arranged opposite to the bottom surface of the arm-type G-shaped seat 1, and is clamped and locked on the arm-type G-shaped seat 1 by the cover 2 to compress the leaky cable The plate 15 is pressed against and pressed against the leaky cable in the supporting arm type G-shaped seat 1.

[0024] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com