Converter parallel control method based on average power feedback

A technology of frequency converter control and average power, which is applied in control systems, control generators, vector control systems, etc., and can solve problems such as increasing equipment volume and increasing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

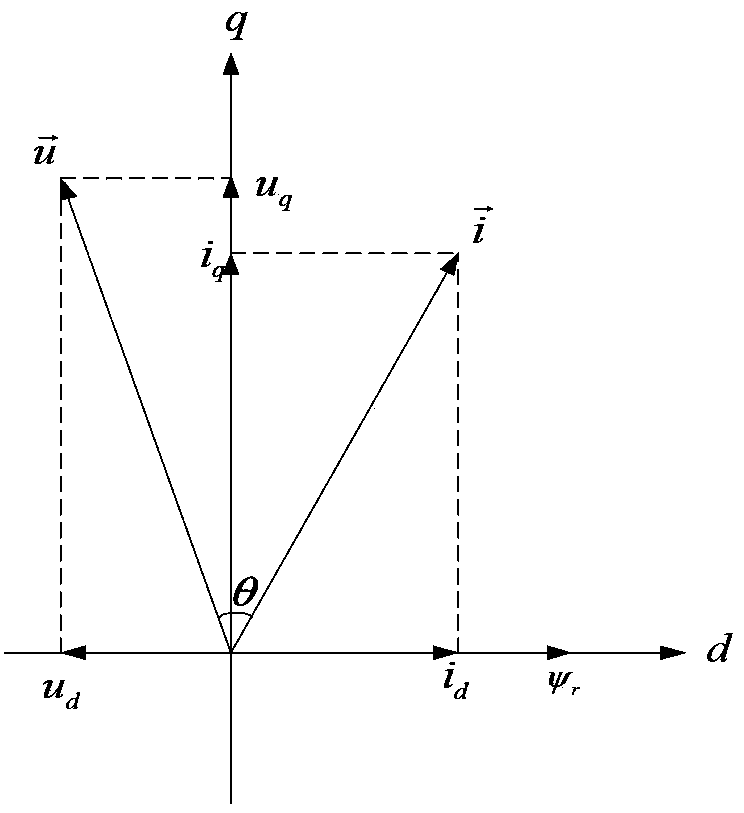

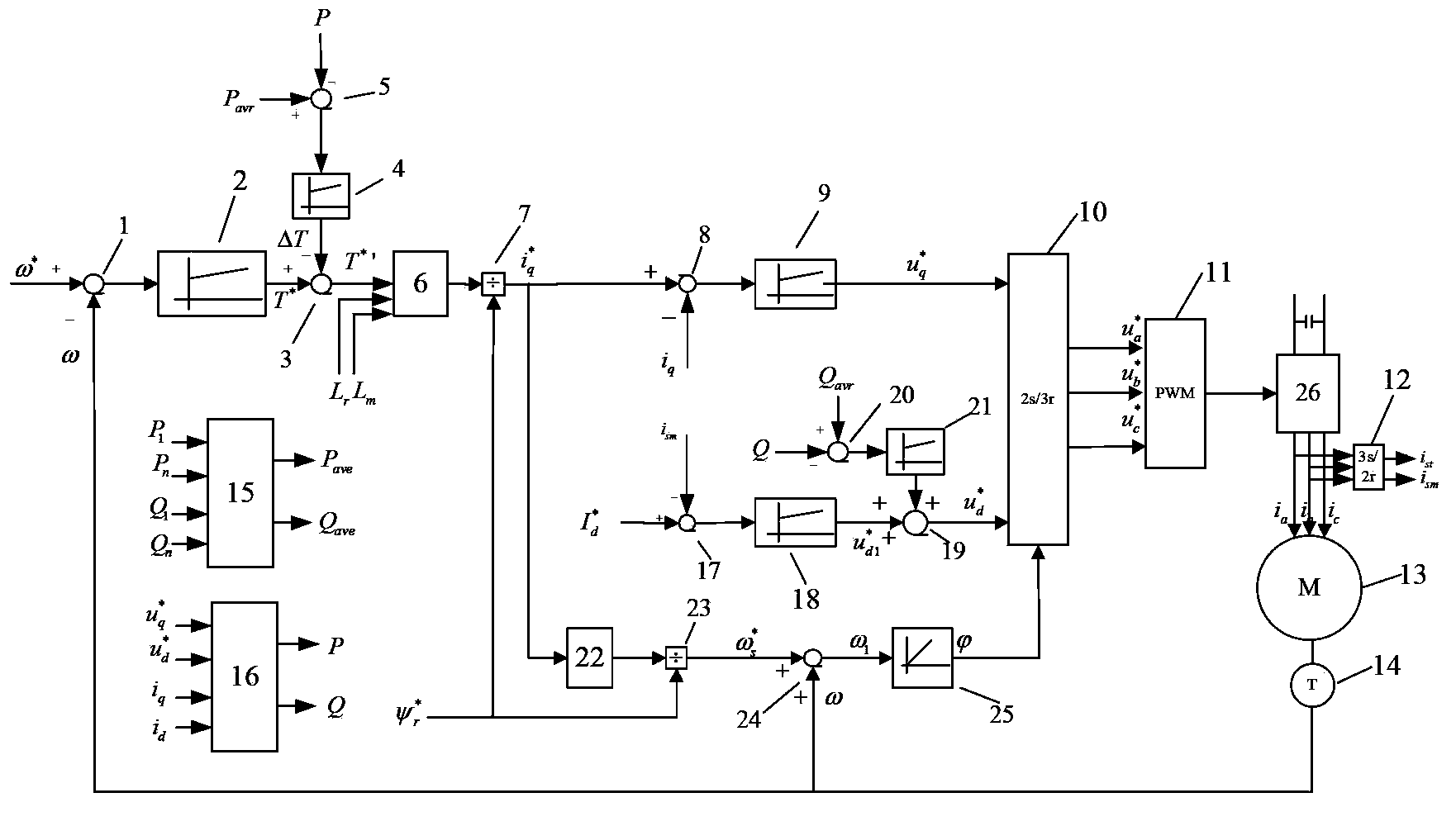

[0053] A frequency converter control method based on average power feedback. Each frequency converter in the frequency converter parallel system converts the actual three-phase output current of the frequency converter into Two-phase relative static current in the rotating coordinate system, and then combine the controller to obtain the reference control voltage in the two-phase rotating coordinate system, and obtain the active power and reactive power of a single inverter in the system; each inverter in the parallel system All inverters receive the active power and reactive power information of other parallel inverters in the system, and calculate the average active power and average reactive power of the inverter parallel system; each inverter in the system is based on the average active power and reactive power Active power is used to adjust its own active power and reactive power, so that each inverter conforms to the power distribution of the inverter parallel system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com