Subsoiler vibrating in staggering way

A deep loosening machine and deep loosening technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve problems such as affecting the operation of the manipulator, the machine is not compact enough, and the working environment is harsh, achieve a good working environment, increase continuity and Stability and power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

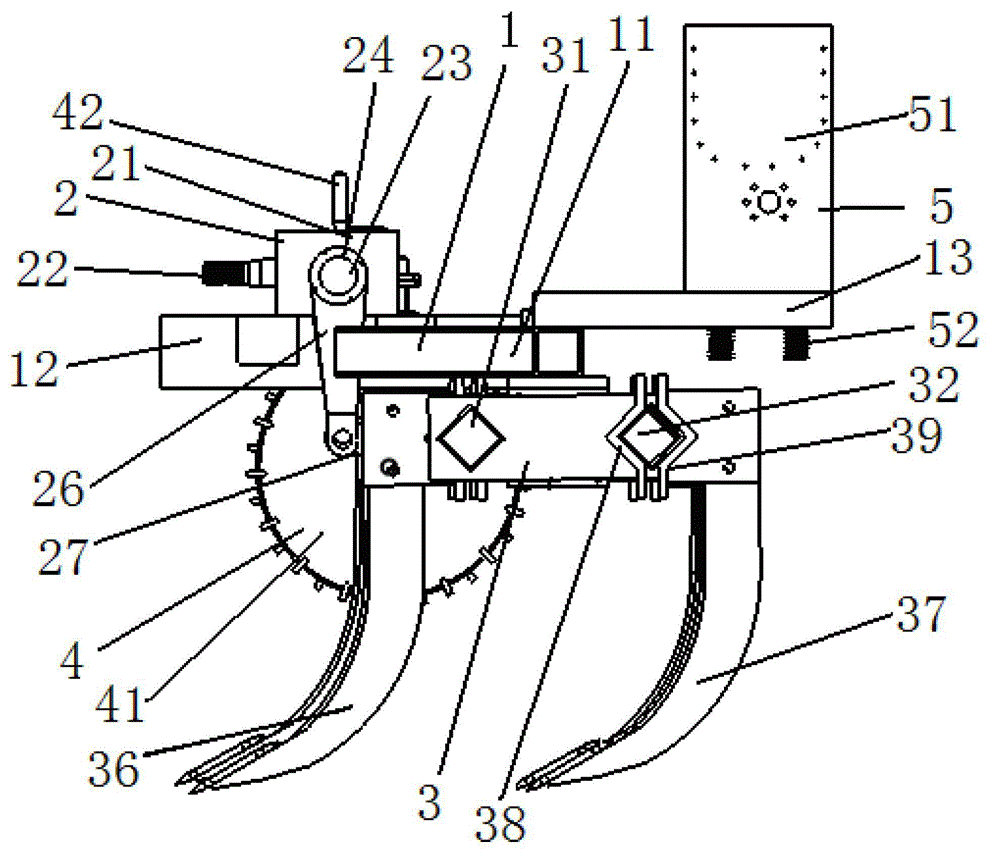

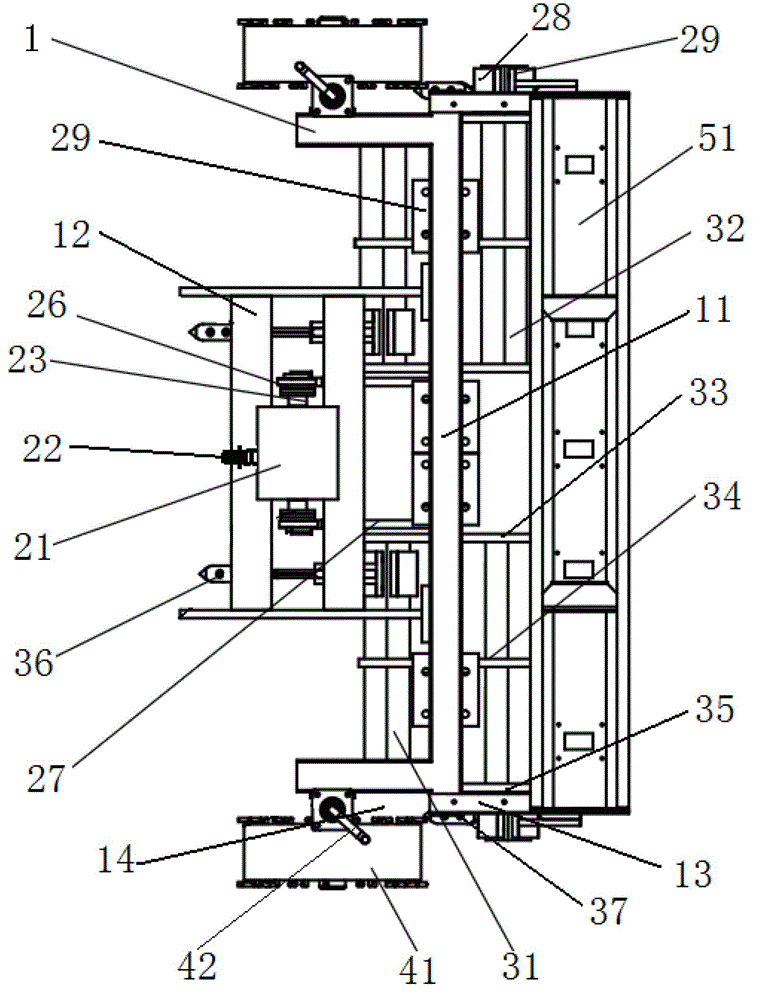

[0019] Such as figure 1 , figure 2 As shown, the present invention includes a frame 1, a subsoiling driving device 2, a subsoiling vibrating device 3, a depth adjusting device 4 and a fertilizing device 5.

[0020] The frame 1 of the present invention includes a main frame 11 and a front extension frame 12 connected to the main frame 11 , a rear extension frame 13 and two side extension frames 14 . It should be noted that the shape of the frame 1 can be set in various shapes according to the needs of installing various components, and details will not be repeated here.

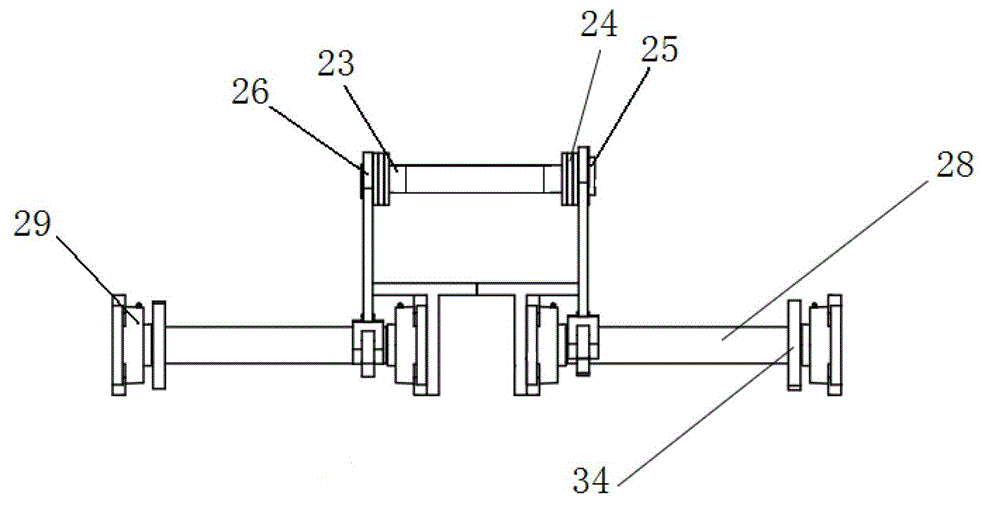

[0021] Such as figure 1 , image 3 Shown, subsoiling driving device 2 of the present invention comprises a gear box 21 that is arranged on frame 1 front stretching frame 12; Two ends of an output shaft 23 protrude from the two side walls of the box 21; the two ends of the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com