Comprehensive treatment method and device for coke oven flue gas pollutants

A technology for comprehensive treatment of pollutants, applied in separation methods, chemical instruments and methods, air quality improvement, etc. the effect of removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

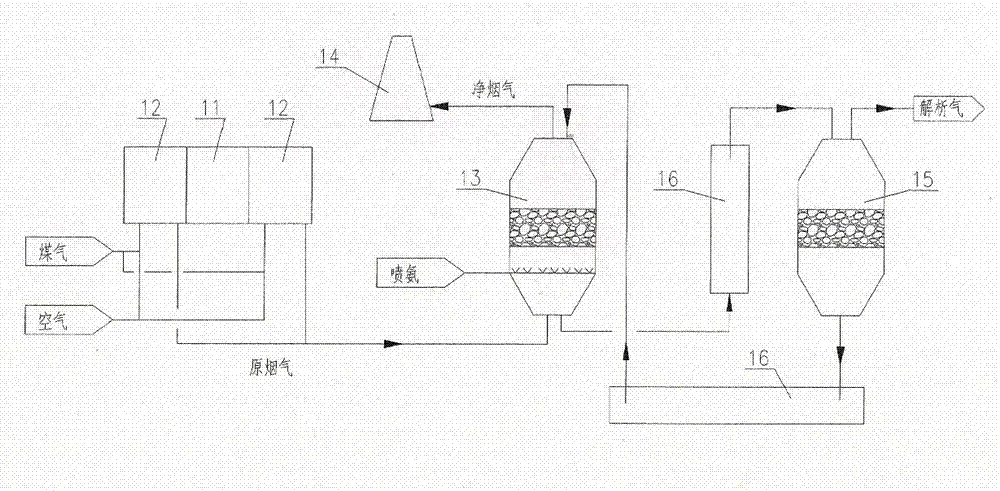

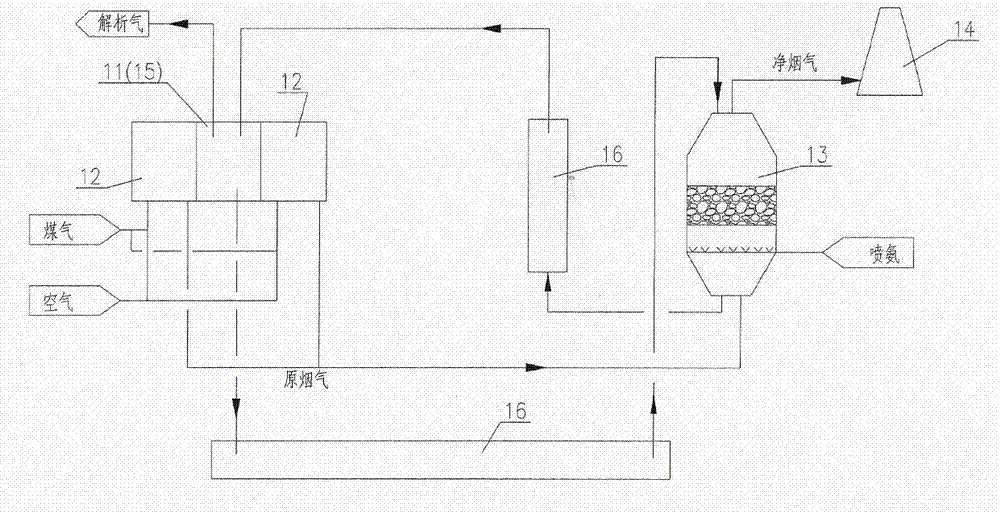

[0021] Such as figure 1 , figure 2 As shown, the main equipment of the process of the present invention includes: a carbonization chamber 11 , a combustion chamber 12 , a pollutant adsorption device 13 , a chimney 14 , an analysis and regeneration device 15 , and an adsorbent transfer device 16 .

[0022] The coke oven consists of a carbonization chamber 11 and a combustion chamber 12 arranged at intervals in sequence. The gas burns in the combustion chamber 12 and supplies heat to the carbonization chamber 11 through partition heat transfer. The flue gas produced is exhausted from the combustion chamber 12 .

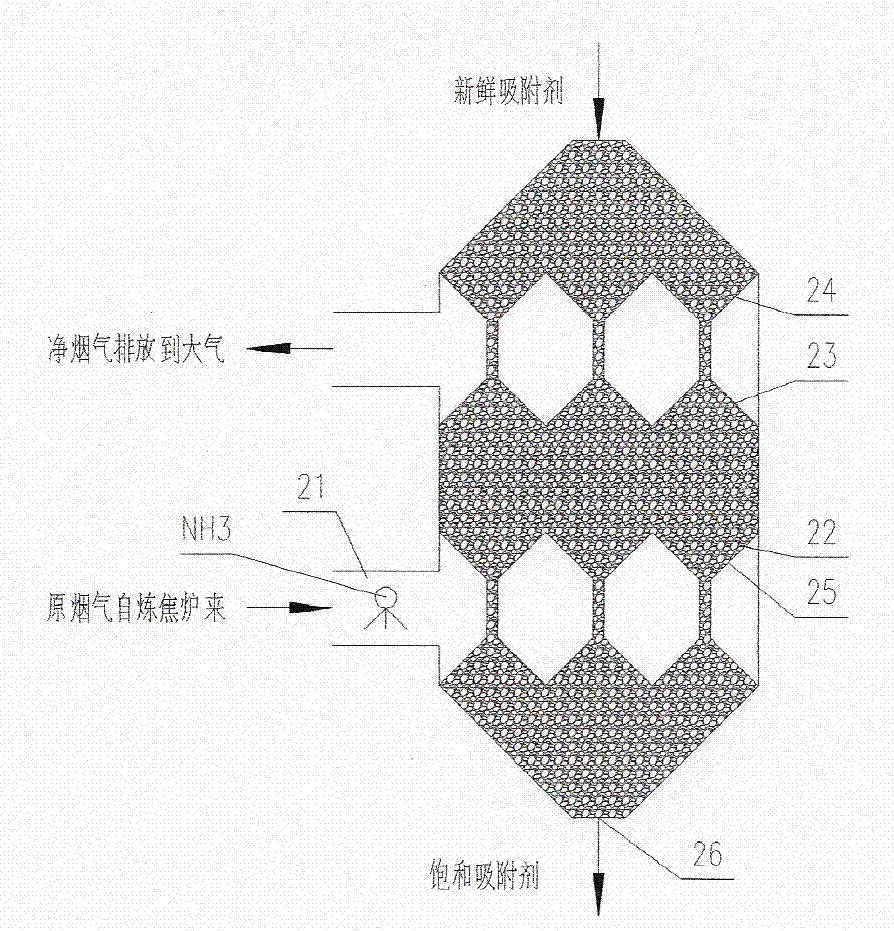

[0023] The pollutant adsorption device 13 of the present invention is a device that accommodates the adsorbent and satisfies the contact between the flue gas and the adsorbent to complete the adsorption process. Its main structure includes: the flue gas ammonia mixing unit 21, the lower gas distribution facility 22, and the adsorbent cloth Facility 24, adsorbent rece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com