Method and device for comprehensively treating pollutants jointly aiming at waste heat recovery of flue gas in coke oven

A technology for comprehensive treatment and waste heat of flue gas, applied in separation methods, chemical instruments and methods, and air quality improvement, etc., can solve the problems of loss of effectiveness of flue gas denitrification process, loss of economy of flue gas desulfurization process, etc., and achieve economical efficiency. removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

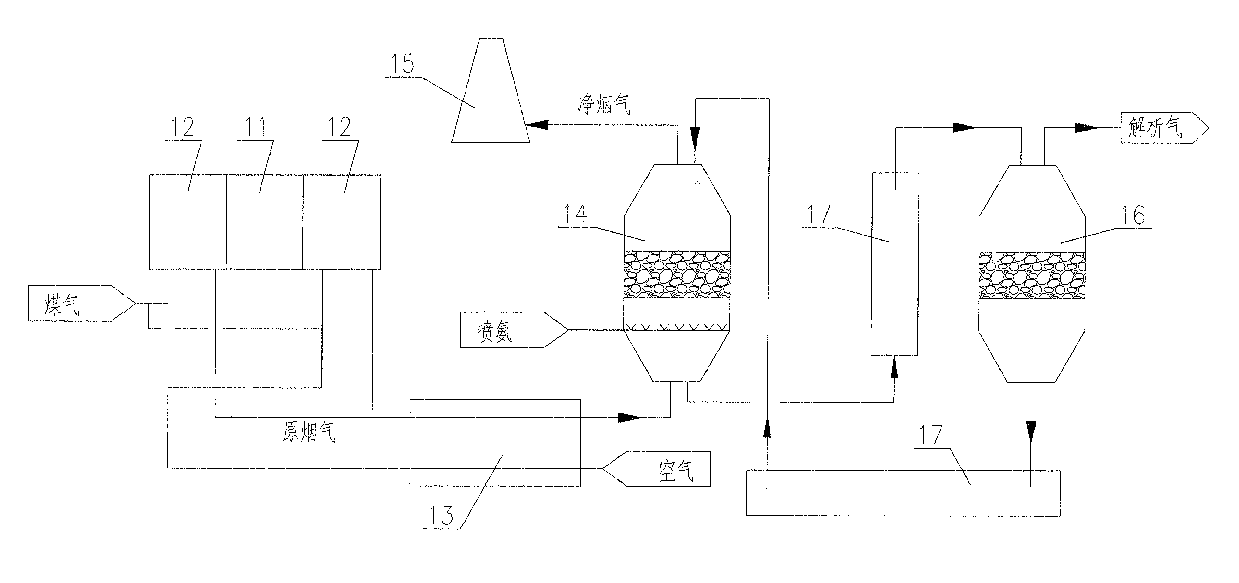

[0022] Such as figure 1 As shown, the process flow of the present invention mainly involves: carbonization chamber 11 , combustion chamber 12 , heat exchanger 13 , pollutant adsorption device 14 , chimney 15 , analytical regeneration equipment 16 , and adsorbent transfer equipment 17 .

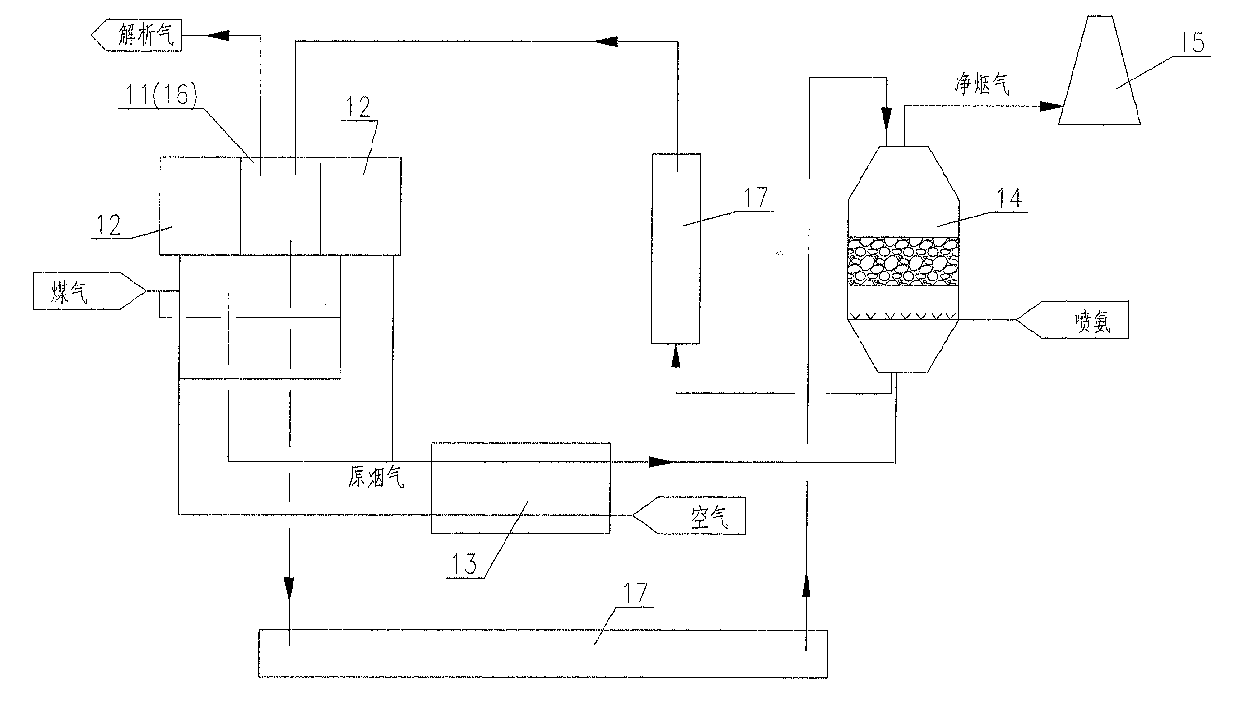

[0023] Wherein the carbonization chamber 11 and the combustion chamber 12 are the integral parts of the coke oven itself, wherein the carbonization chamber 11 can serve as the analysis and regeneration equipment 16 in a certain specific embodiment, and the combustion chamber 12 receives heated air and may be modified accordingly, see image 3 . Such changes should be considered within the scope of the present invention.

[0024] The coke oven consists of a carbonization chamber 11 and a combustion chamber 12 arranged at intervals in sequence. The gas burns in the combustion chamber 12 and supplies heat to the carbonization chamber 11 through partition heat transfer. The flue gas produced is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com