Elbow welding device

A welding device and elbow technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficulty in ensuring the space angle between two elbows and poor welding quality, and achieve easy use and promotion, improve quality, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

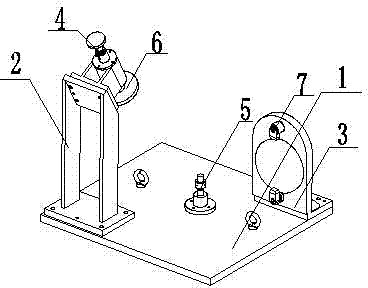

[0011] Such as figure 1 It is a schematic diagram of the structure of the present invention, a bending pipe welding device, including a base plate 1, a positioning bracket 2, a positioning bracket 2 3, a telescopic positioning mandrel 4, a support 5, a positioning disc 6 and a clamping piece 7, and a base plate 1 One side is provided with a positioning bracket 2, and the other side is provided with a positioning bracket 2 3, the positioning bracket 1 2 is fixedly connected with the telescopic positioning mandrel 4, the center of the equipment base plate 1 is provided with a support 5, and the end of the telescopic positioning mandrel 4 A positioning disc 6 is provided, and a clamping part 7 is provided on the positioning bracket 2 3 .

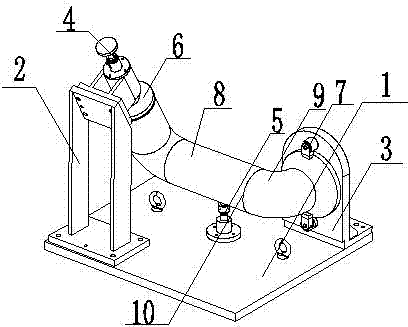

[0012] When used, such as figure 2 As shown, first position the flange end of the elbow B9 on the positioning bracket 2 3, and at the same time clamp it on the positioning bracket 2 3 with the clamping piece 7; then place the outlet end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com