Temperature equalizing system and method for autoclave

A technology of uniform temperature system and autoclave, which is applied to electrical components, generators/motors, etc., and can solve problems affecting the utilization rate of autoclaves and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

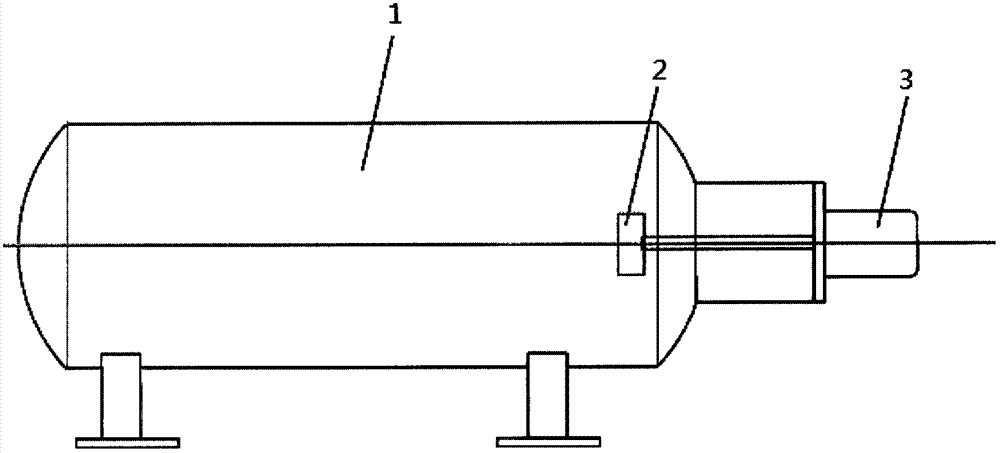

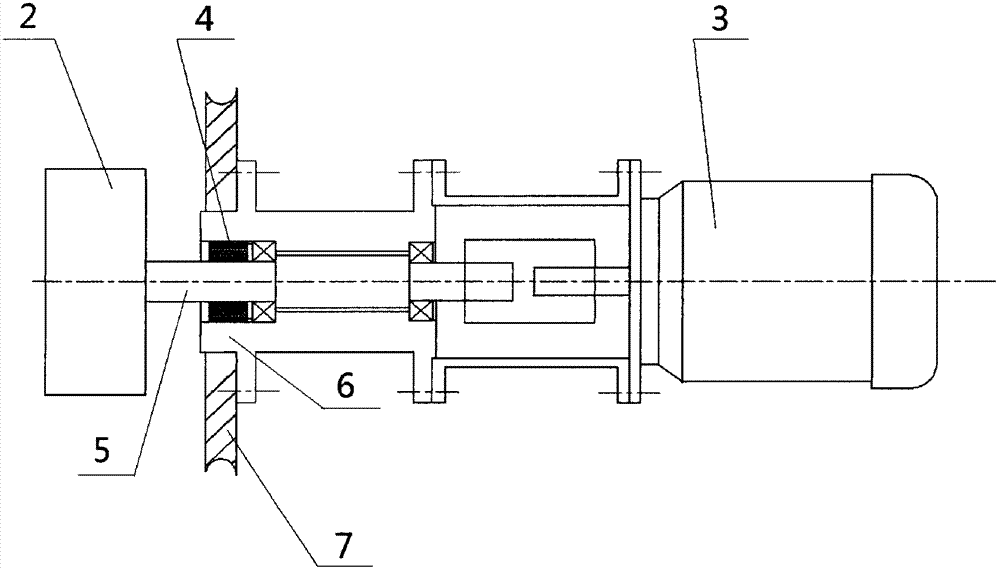

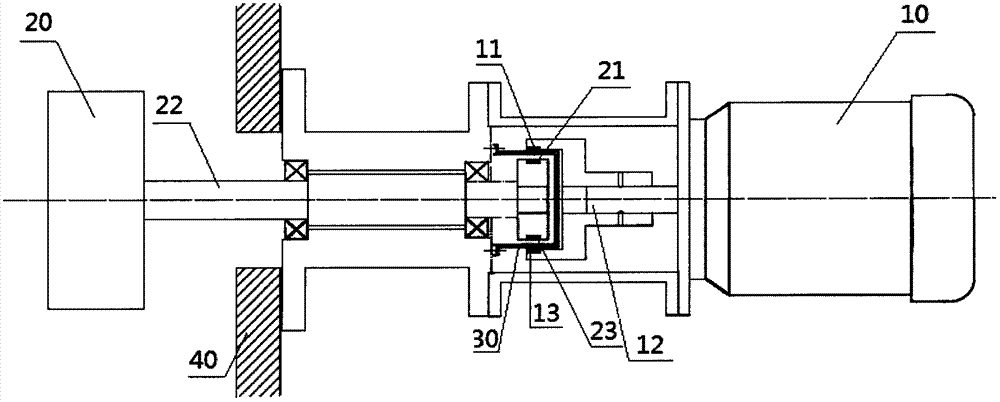

[0058] image 3 An embodiment of the temperature equalization system for autoclave of the present invention is shown. The autoclave in this embodiment belongs to small and medium-sized autoclave, and can be used for manufacturing or conducting experimental research on fiber-reinforced resin-based composite materials. In this embodiment, the autoclave includes parts such as a cylindrical tank body, a vacuum system, and an air compression system, and generally has the following parameters:

[0059] 1. Tank specifications: Circular pressure vessels, manual clutch switching methods, and combined with gear shift door switching; the pressure is 0.1MPa ~ 10.0MPa, especially 0.1MPa ~ 3MPa; the use temperature is 50 ℃ ~ 500 ℃ , especially 130~300℃; the effective space of the tank is 2L~100000L, especially 10L~100L; pressurized with air;

[0060] 2. Vacuum system: AC220V~380V, vacuum pump (0.3KW~0.5KW);

[0061] 3. Heat source: 4KW~100KW electric heater, especially 5KW~20KW electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com