Vibration-proof rail fixed type automatic guided vehicle system

An automatic guided vehicle and fixed technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems affecting the safety and stability of the logistics transportation system, the track is prone to tilt or rollover, and the goods are damaged and other problems, to achieve the effect of low cost, prevent sideslip, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

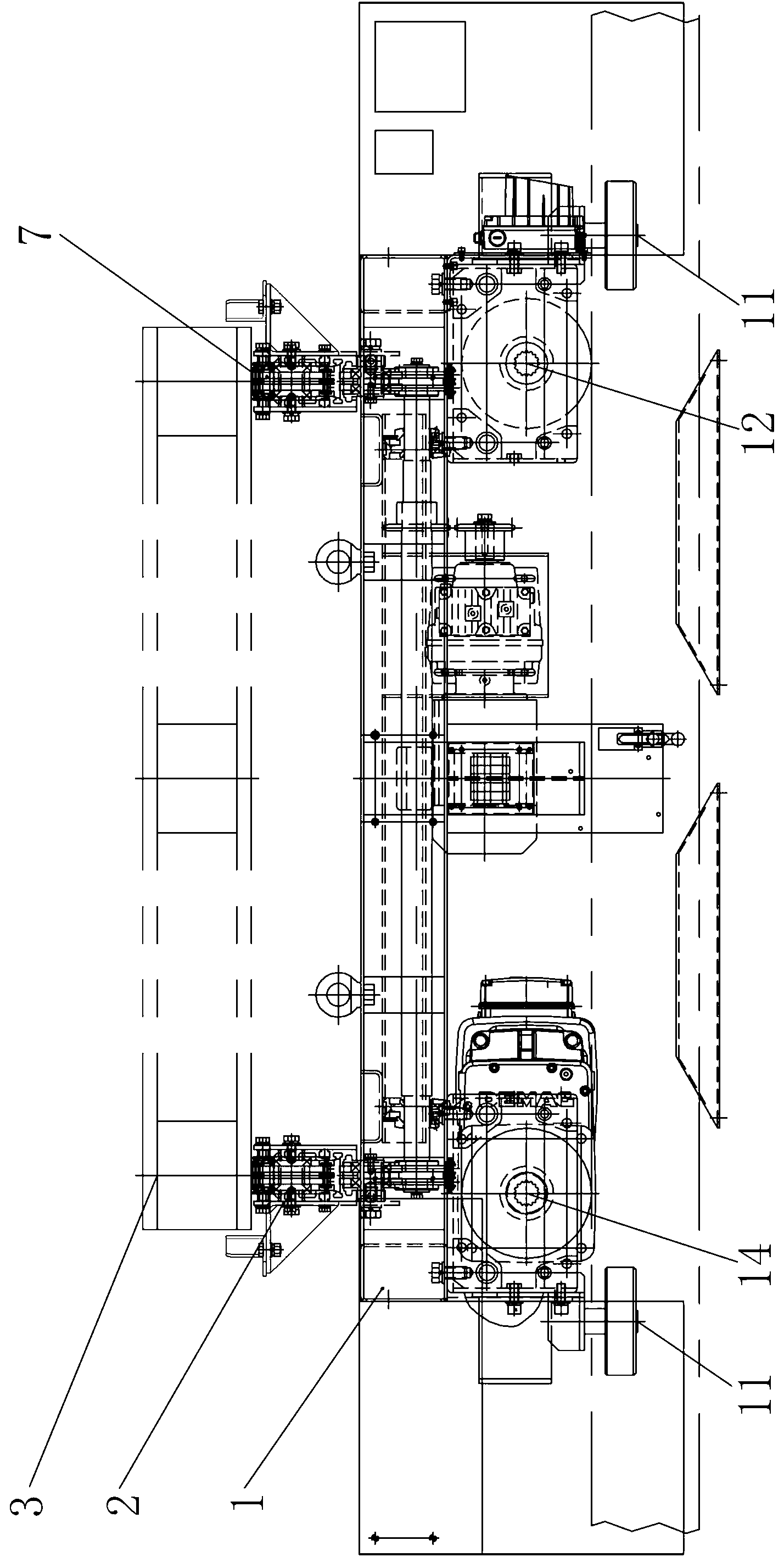

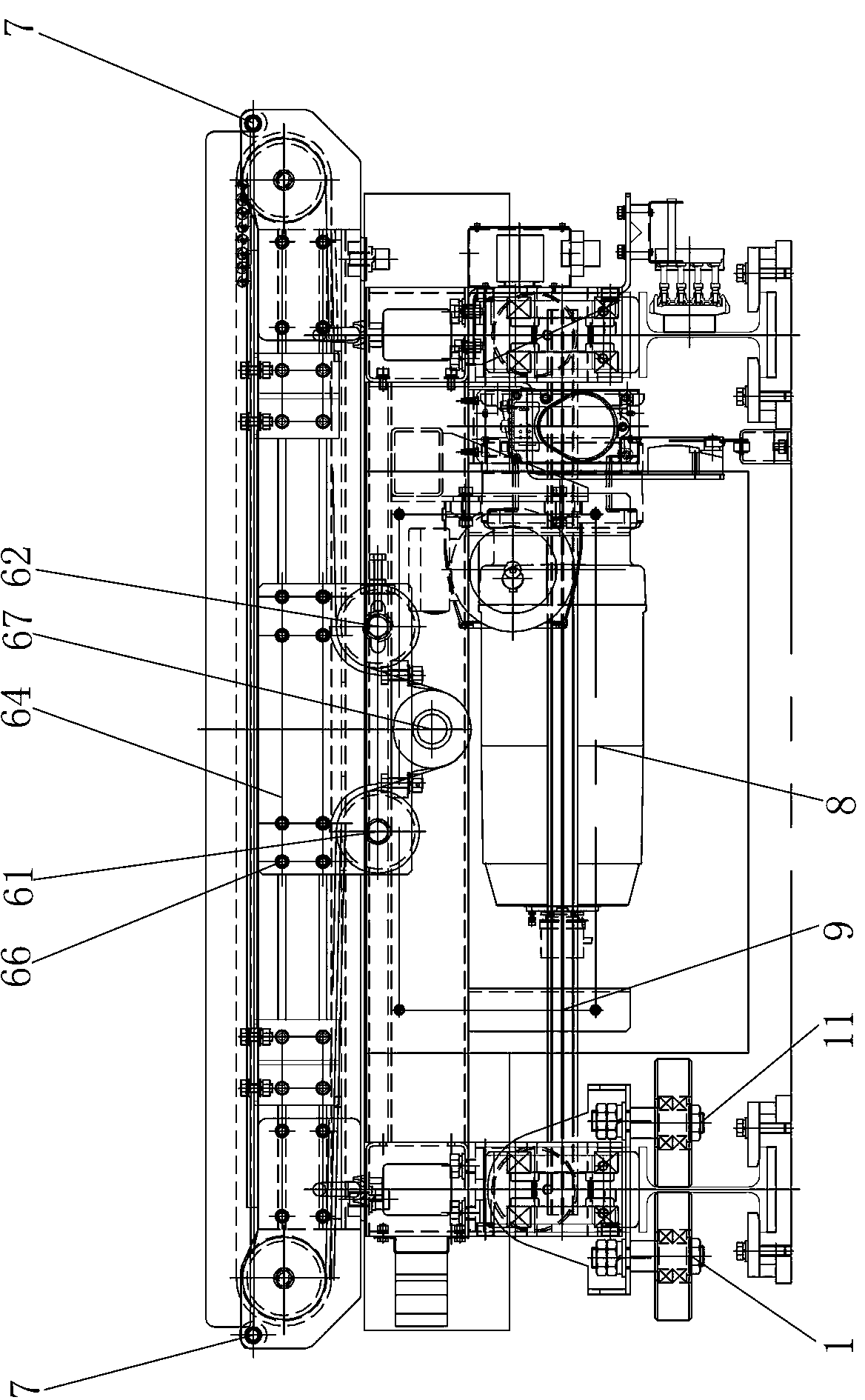

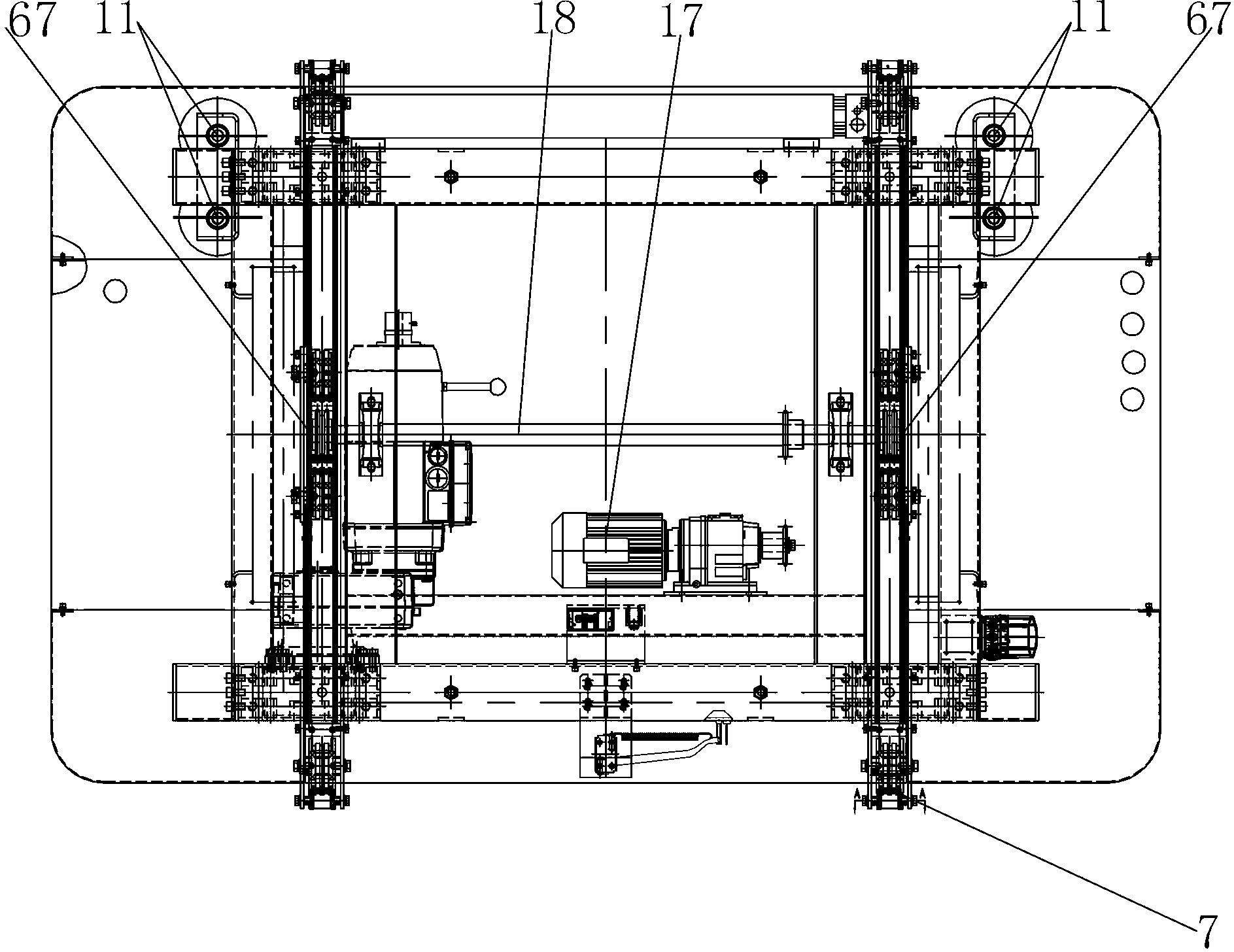

[0035] like Figure 1 to Figure 3 As shown, an automatic guided vehicle is provided with a transfer device 2 on the automatic guided vehicle, that is, a double-row chain chain conveyor; the described automatic guided vehicle also includes a walking frame 1, and the double-row The chain chain conveyor also includes a decelerating motor 17 and a transmission shaft 18 which are arranged on the walking vehicle frame 1 and are chain-driven to each other; wherein, the two ends of the transmission shaft 18 are respectively connected with double chain The driving sprocket 67, the traveling vehicle frame 1 is carried by the moving wheel set. The moving wheel set includes a walking wheel box, the moving wheel set includes a driving wheel set 14 and a driven wheel set 12, and the driving wheel set 14 includes an involute spline shaft 9 that is connected to each other and is located on the walking wheel. Motor 8 on the wheel box.

[0036] The above-mentioned automatic guided vehicle inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap