Propelling mechanism

A push mechanism and push plate technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high production cost, complex structure, unreliable action, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

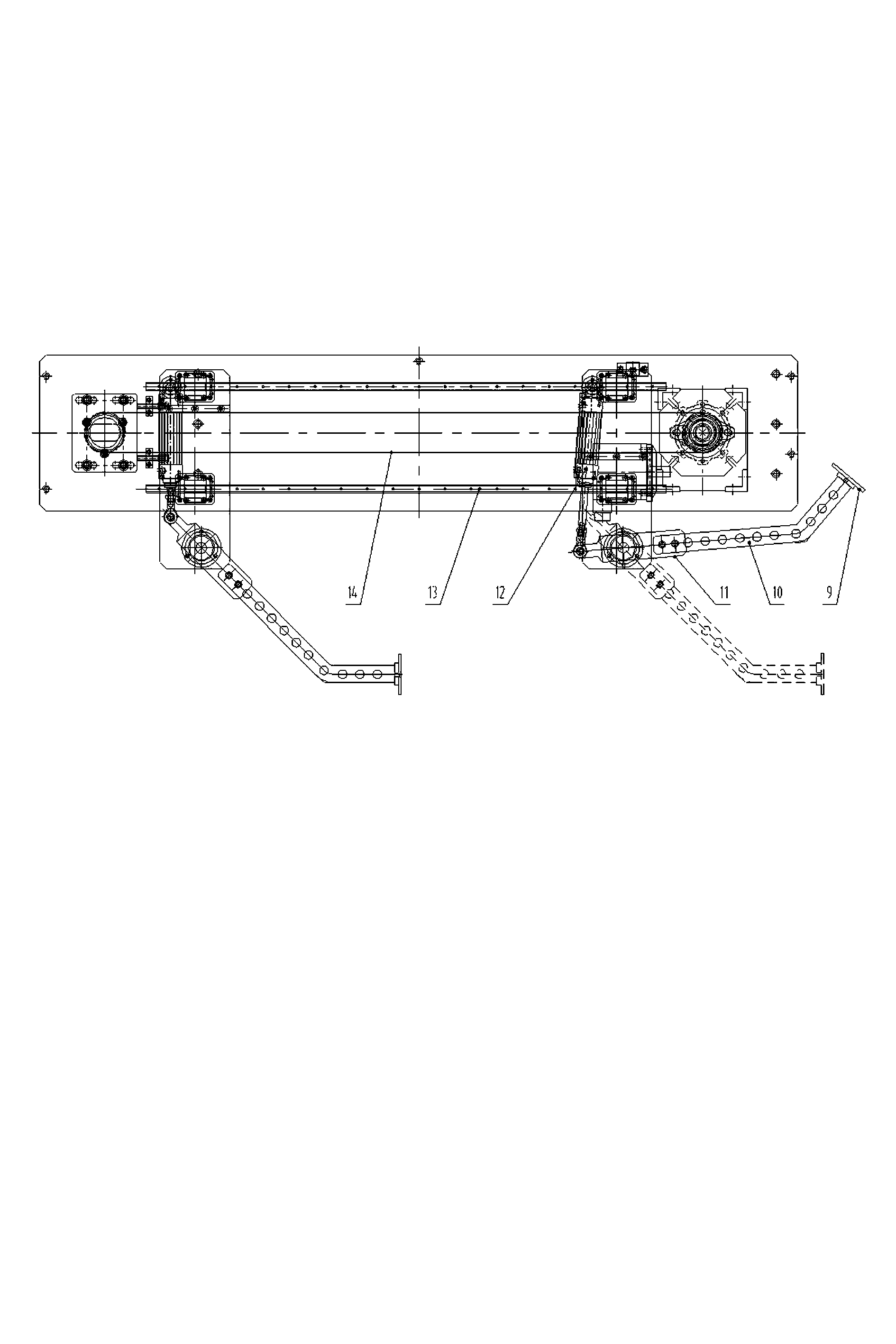

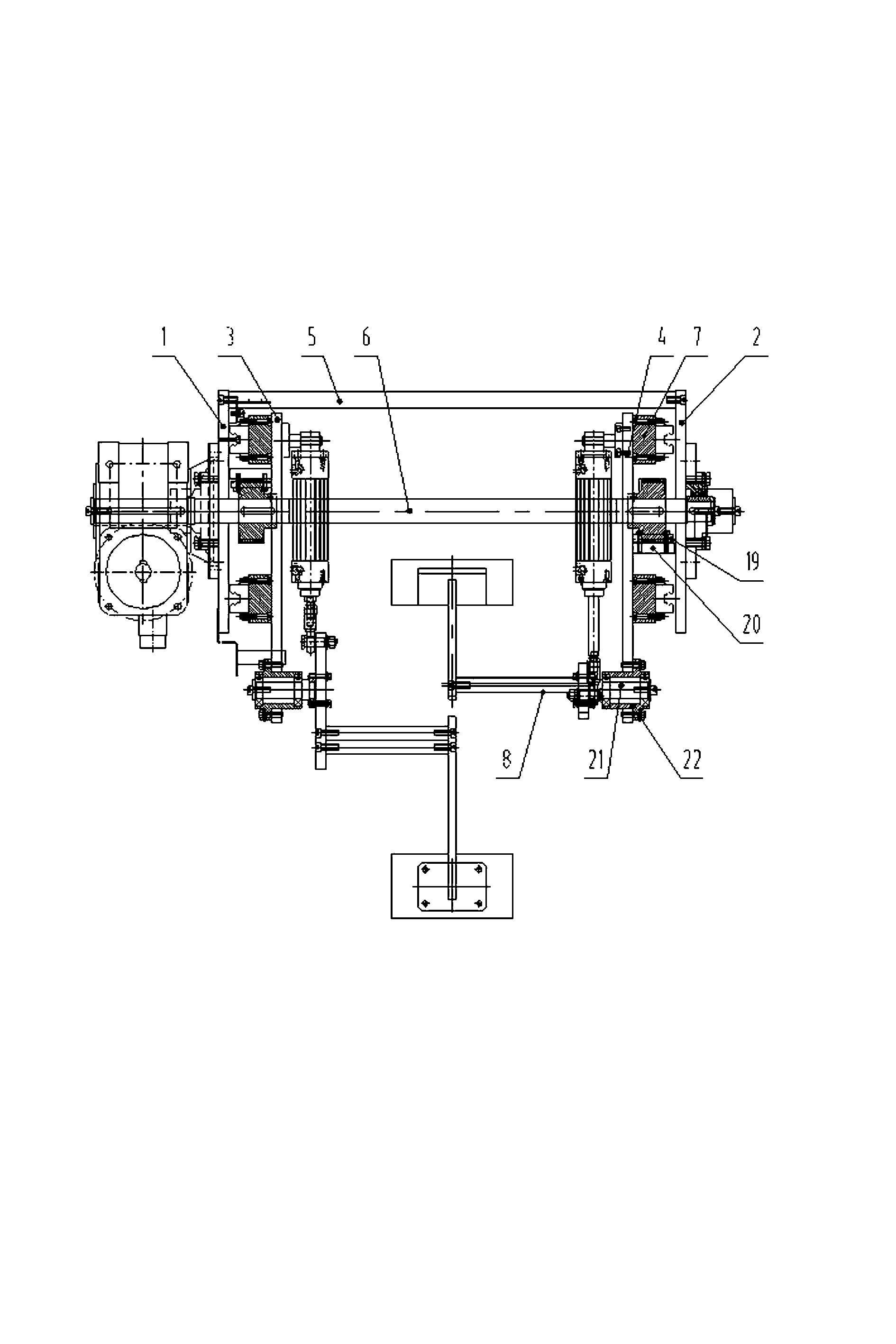

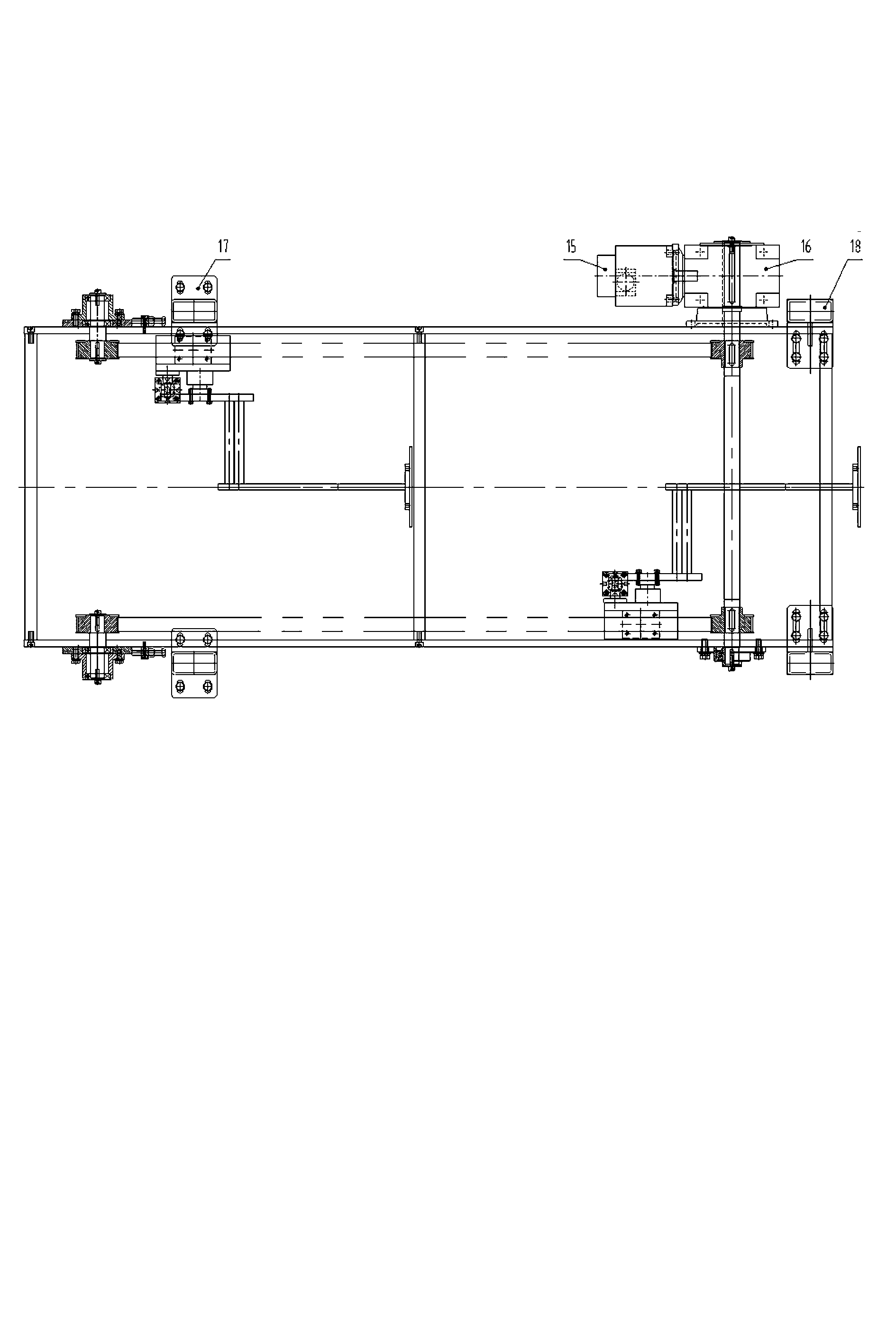

[0009] A push mechanism, including two groups of push hand mechanisms, slide plates 3, 4 are the cornerstones of the push hand mechanism, a fixed block 20 is installed on one side of the slide plates 3, 4, and the fixed block 20 is connected with a splint 19 with a toothed groove, through The splint 19 with the toothed groove can fix the left and right slide plates 3 and 4 on the left and right synchronous belts 14 respectively. 7. The other end of the connecting plate 7 is fixed on the slider of the linear guide rail 13 (the slider belongs to a part of the linear guide rail, and forms a linear motion guide rail pair together with the guide rail part of the linear guide rail). In this way, the timing belt can pull the slide plate and even all the parts installed on the slide plate move back and forth on the linear guide rail together. The other side of the slide plate is equipped with a cylinder 12 (upper position) and a bearing seat 22 (lower position), and a rotating shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com