Automatic multiplying power changing device of tower crane

A tower crane and magnification change technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve problems such as reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

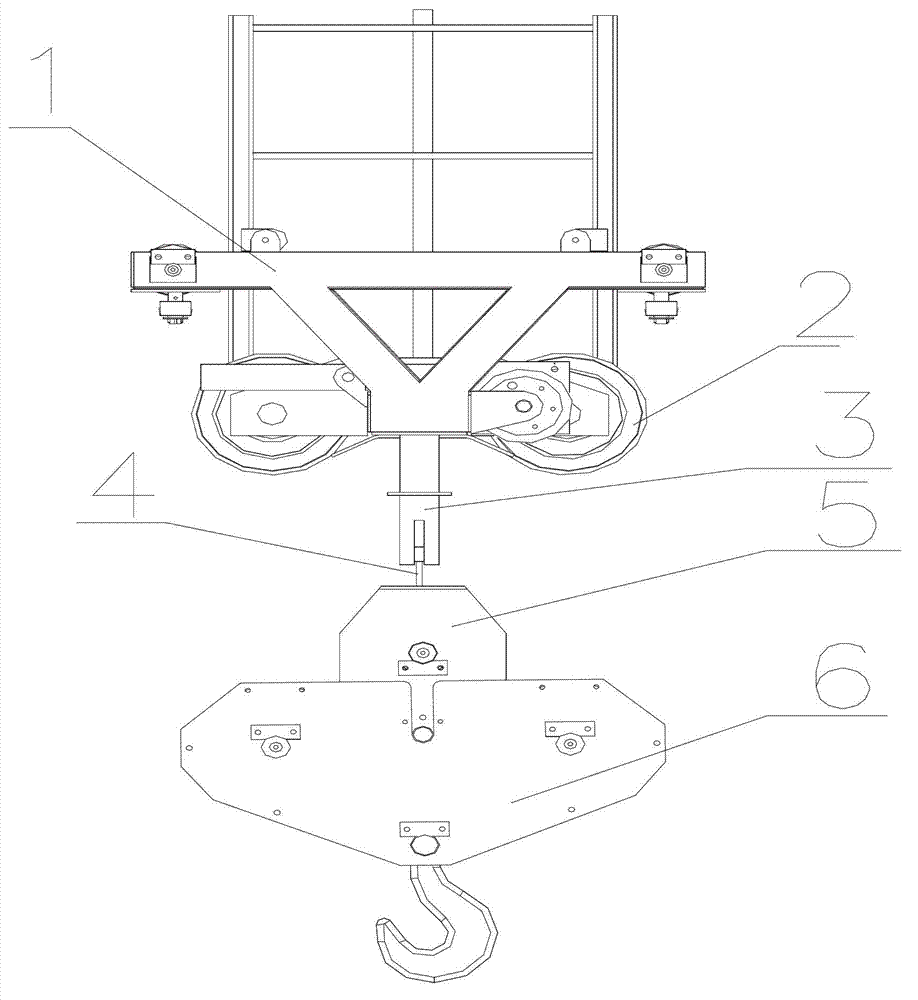

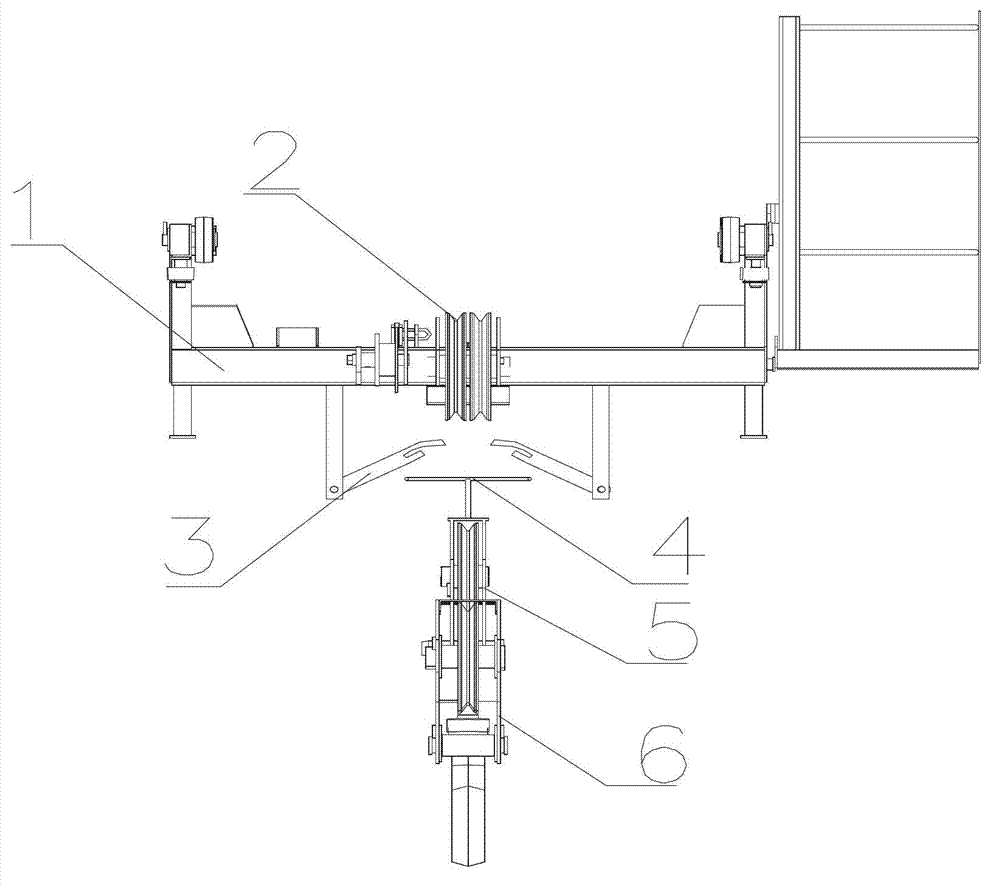

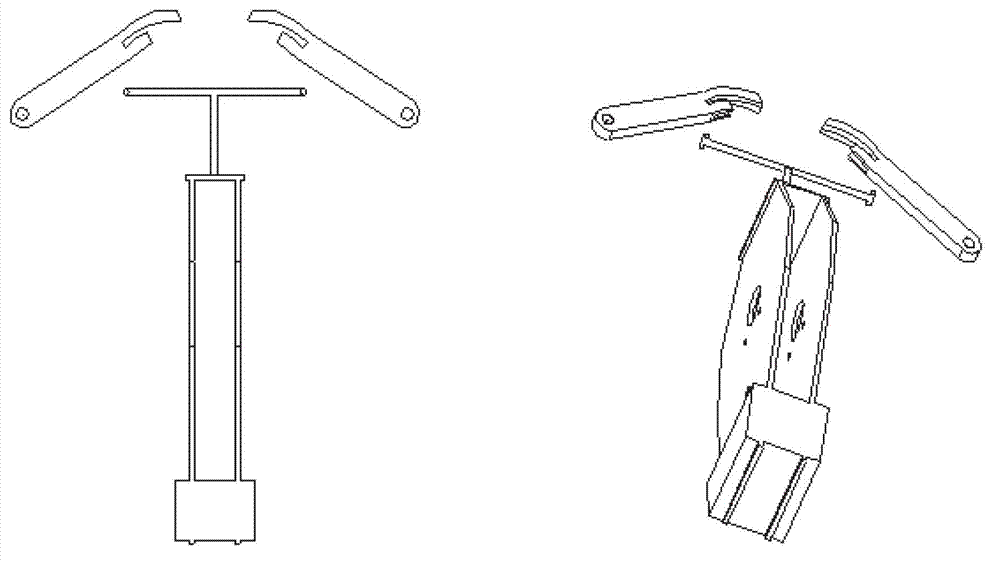

[0013] Such as Figure 1-9 As shown, the device includes a load trolley and a hook assembly, wherein the load trolley includes a trolley 1, a runner 2, a handle fixing rod, and a handle 3, and the hook assembly includes an I-shaped connecting rod 4, a pulley block 5, and a hook set 6 , wherein, two runners 2 for guiding the rope are installed on the trolley, and the key components gripper fixing rod and gripper 3, which are used to realize magnification conversion, are installed on the main beam of the trolley. Back-moving spring is arranged, and the I-shaped connecting rod 4 that is used to connect gripper and the pulley block 5 that realizes magnification conversion are welded on the pulley block, and suspension hook and two runners that are used for guiding rope are housed on the hook block 6 .

[0014] Such as Figure 8 The figure shows that the double ratio is generally used for light loads. At this time, the pulley block is stuck in the slot of the hook block due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com