Module type moveable flood-preventing wall

A flood control wall and modular technology, applied in dikes, coastline protection, dams, etc., can solve the problems of long gate opening time, increased transportation costs, and troublesome sandbag handling, etc., and achieves the effect of convenient installation, low transportation and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

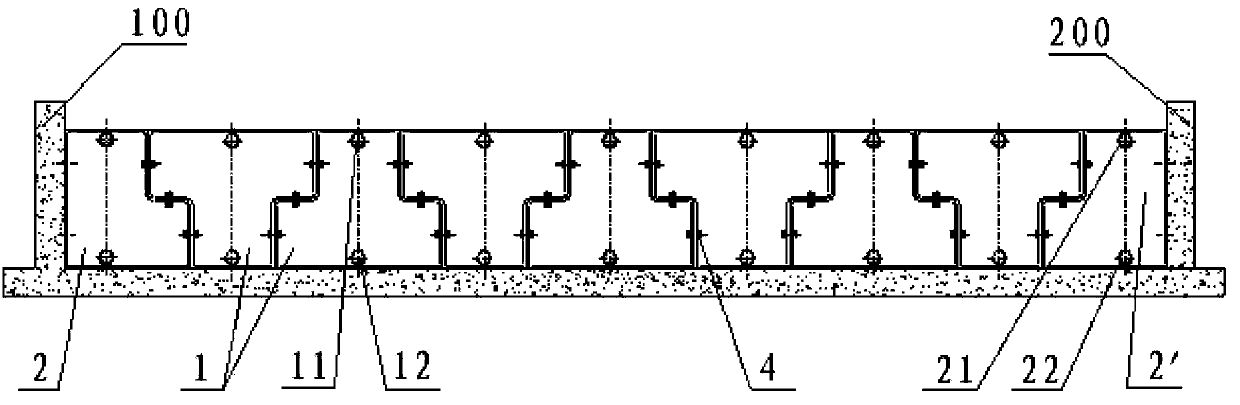

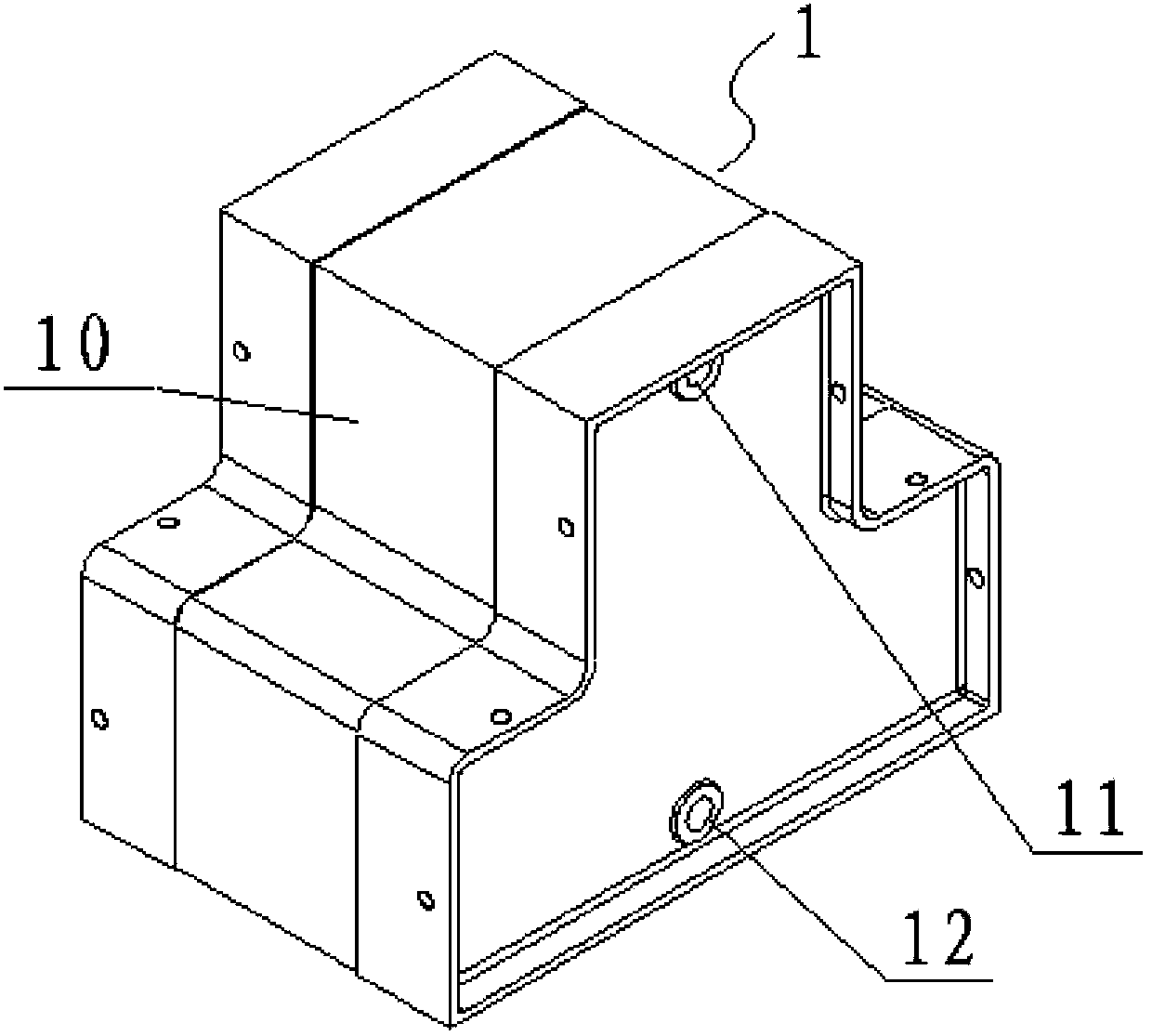

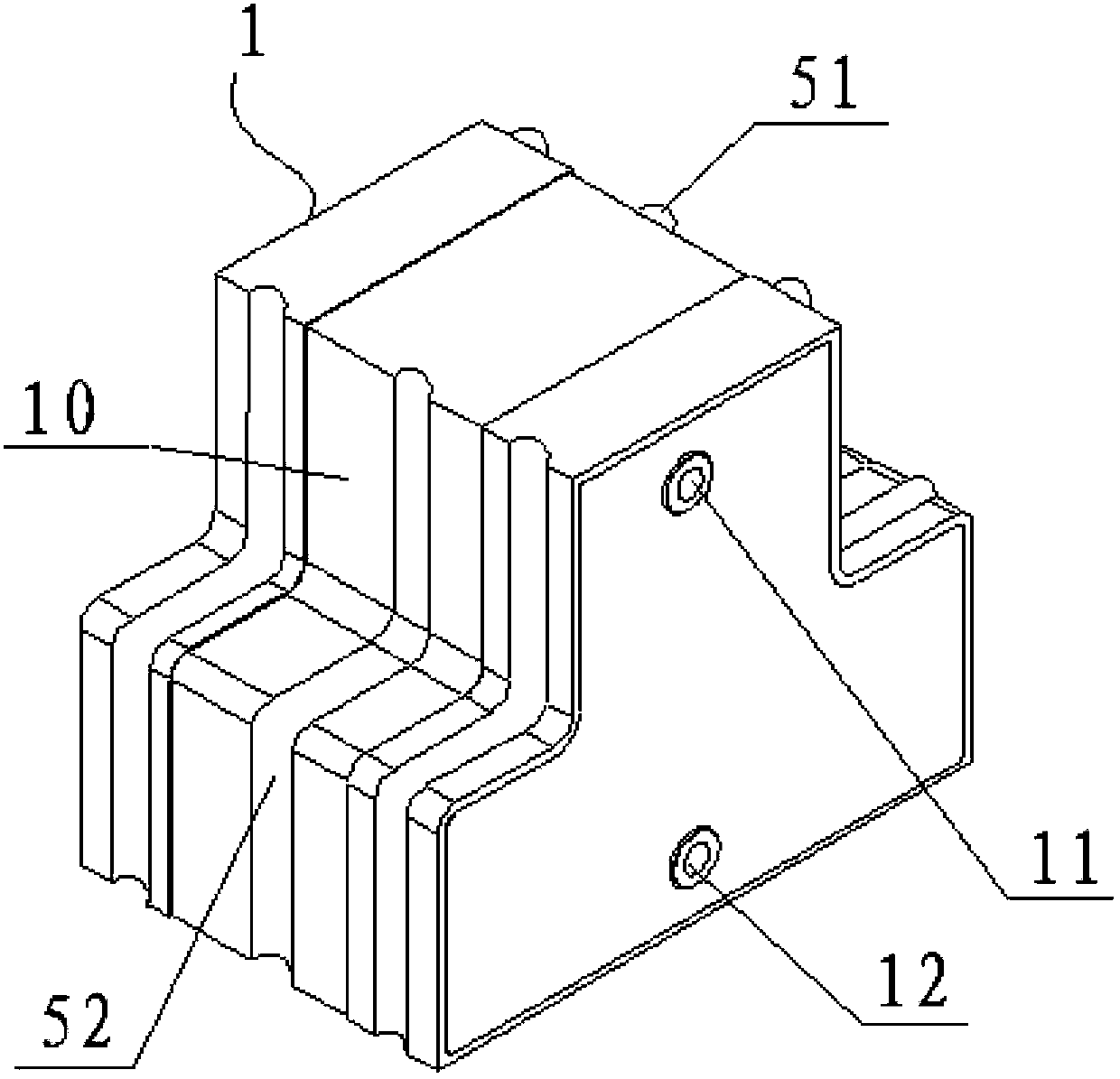

[0022] see Figure 1 to Figure 3 , a modular movable flood control wall of the present invention is installed between two building walls 100,200. The modular movable flood control wall includes several standard modules 1, a pair of end modules 2, 2', several fastening mechanisms and several connecting mechanisms, among which:

[0023] The standard module 1 is made of polyvinyl chloride plate and is a hollow block with a T-shaped cross section. Each standard module 1 is provided with a sealing strip 10 on both sides and the middle of the upper and lower end surfaces. The width of the sealing strip 10 is 1 The thickness of the sealing tape 10 is 2-5 mm; the upper and lower parts of the front face of the standard module 1 are respectively provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com